Automatic driving stringing monorail crane

An automatic driving and monorail crane technology, applied in the direction of load hanging components, cranes, earthwork drilling and mining, etc., can solve the problems of large size, inconvenient maintenance of hydraulic station, etc., and achieve the effect of low noise, simple structure and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

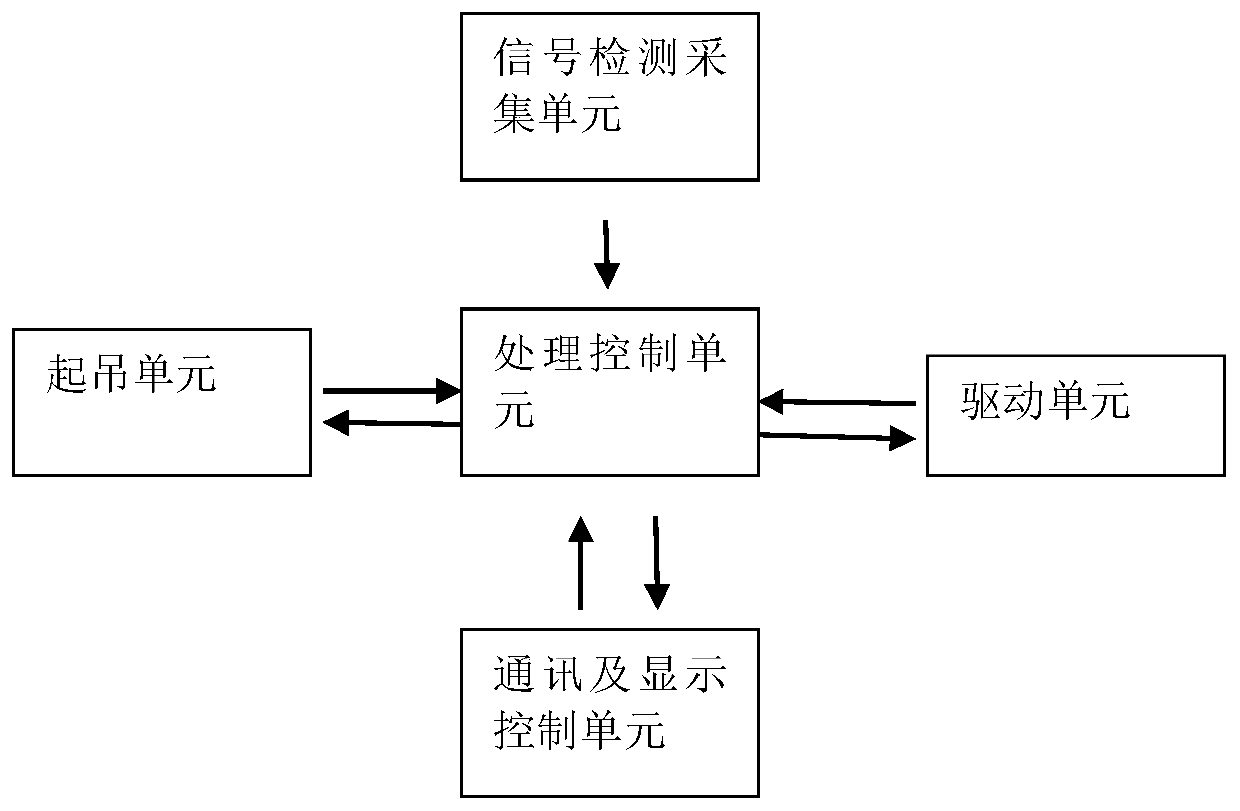

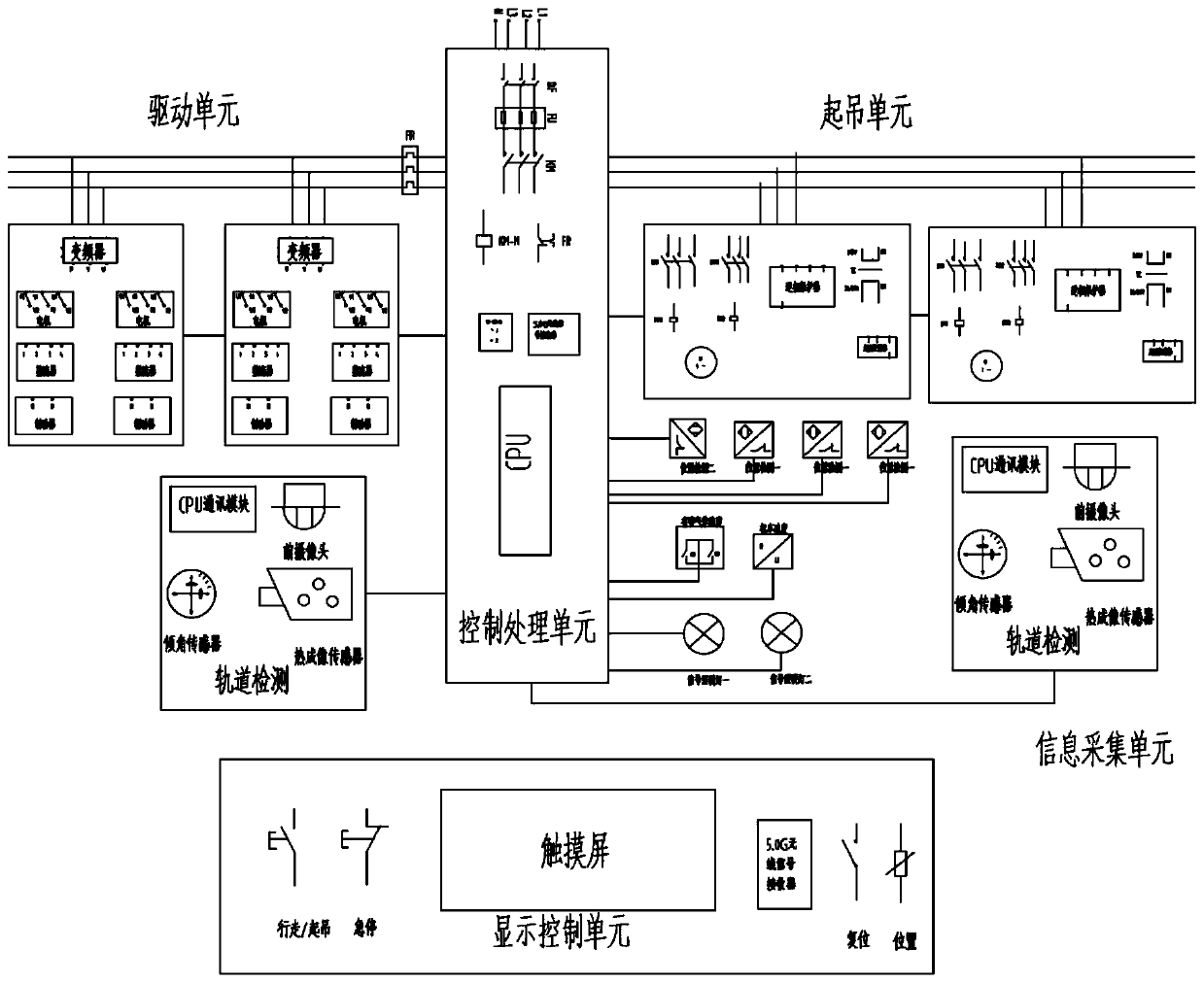

Method used

Image

Examples

Embodiment 1

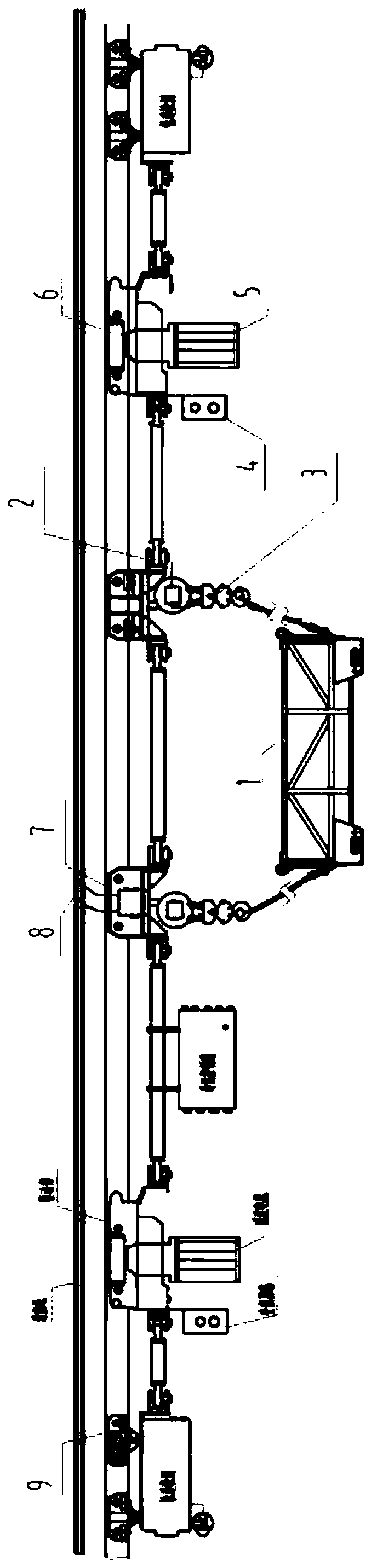

[0029] Such as figure 1 As shown, an automatic driving wire monorail crane includes a load-bearing rail, a locomotive and a control device. Conductive rails are arranged on both sides of the load-bearing rail. The conductive rails are connected to the driving part of the locomotive. The control device is connected to the driving part.

[0030] Unmanned driving is realized through remote control, and people and vehicles are separated, reducing the risk factor of people in dangerous areas or other sudden accidents. Realize the safety and environmental protection of the roadway production working face.

[0031] The locomotive includes a carrying trolley 7 and a speed measuring trolley 9, and the driving part of the carrying trolley 7 is connected to a conductive track through a collector. The conductive track, that is, the power line 8, adopts a finger-protected single-pole insulated power supply system. It solves the safety problem of live power supply with bare wires in commo...

Embodiment 2

[0052] On the basis of Embodiment 1, the motor of the driving part is a DC motor. The corresponding power supply system can be replaced by a DC system.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap