Installation and use method of active support prefabricated secondary lining for shield tunnel

A technology for secondary lining and shield tunneling, which is applied in tunnel lining, tunnel, shaft lining, etc., can solve the problems of emptying of the track bed and segment structure, segment cracking, and excessive deformation of the tunnel structure, so as to achieve a simple lining structure. , Improve the stress state, the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

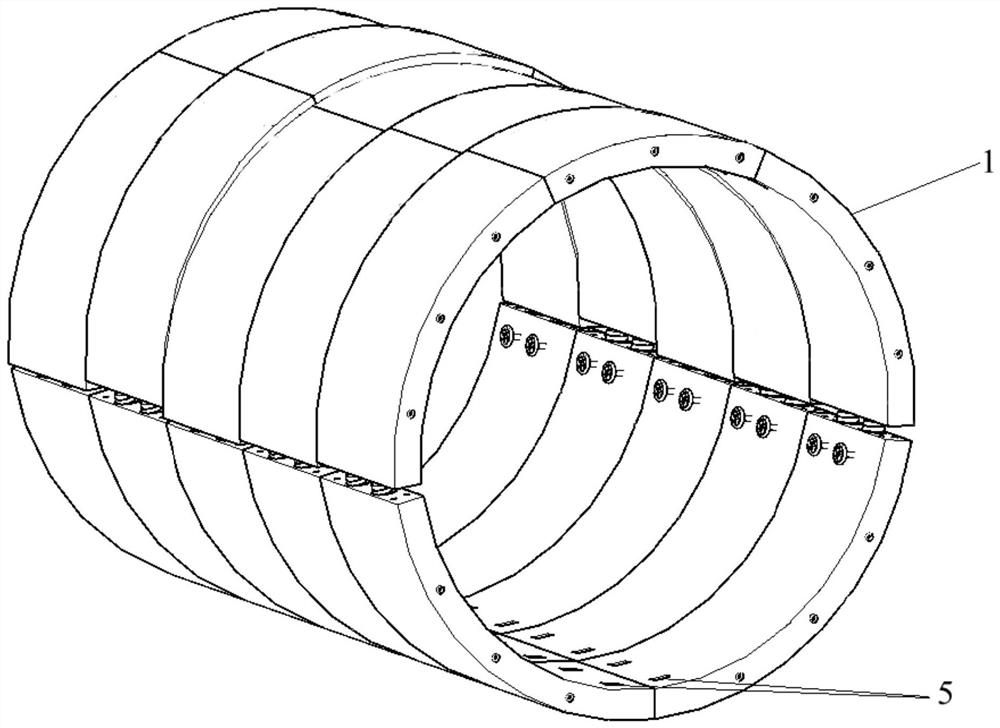

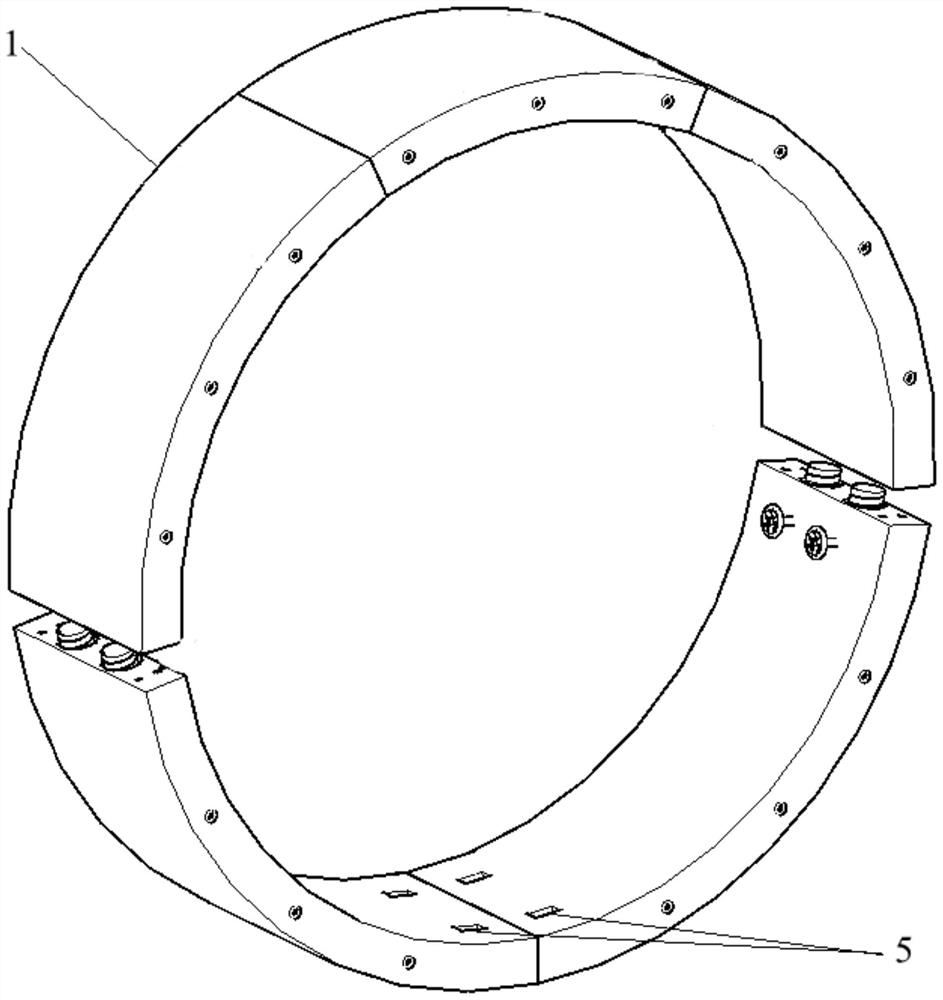

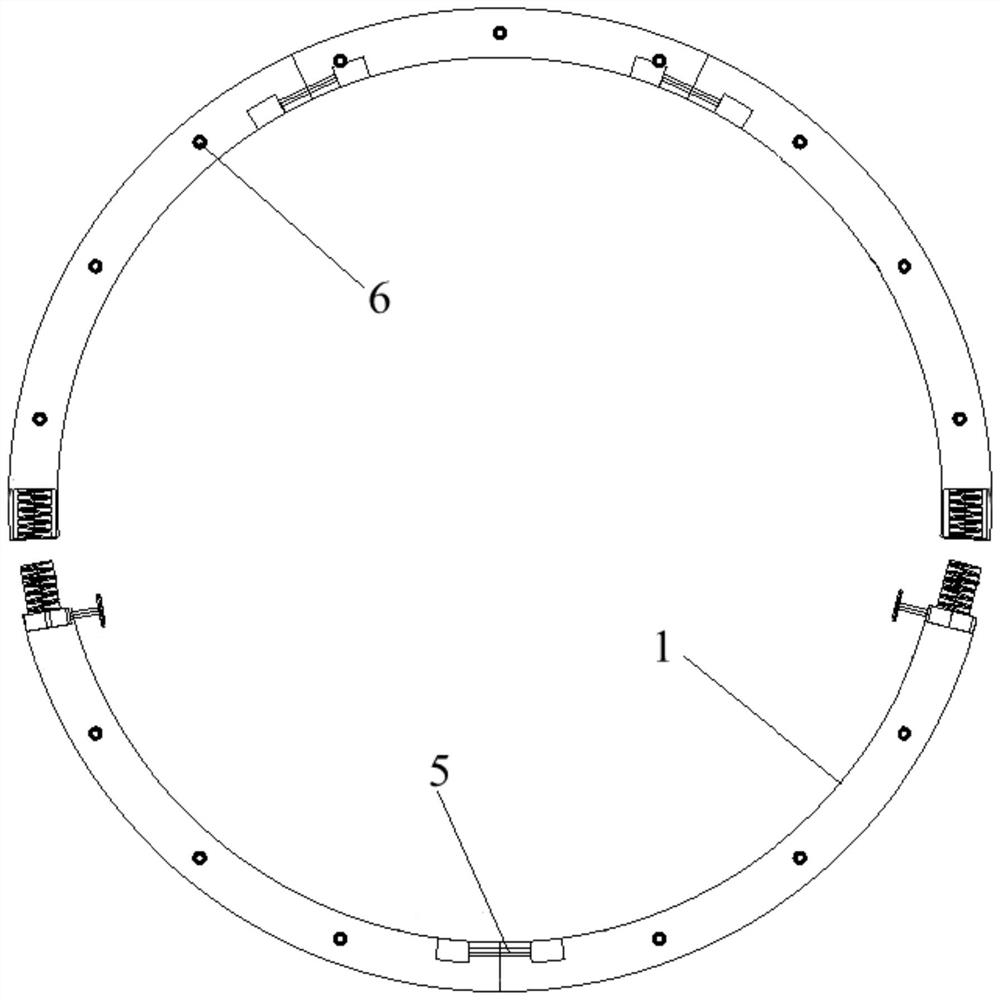

[0035] The preferred embodiment of the present invention provides an active support prefabricated secondary lining for shield tunnels, which includes a lining ring 1 spliced by a plurality of symmetrical arc-shaped lining blocks. The lining blocks are flexibly connected by a telescopic joint device, so that the two lining blocks can be flexibly stretched apart, the other lining blocks are connected by a ring joint 5, and the lining rings are longitudinally connected by steel cables. Between the rings 1 is a through-seam structure.

[0036] The entire secondary lining structure should adopt an axisymmetric structure in the transverse direction, and the telescopic joint device is installed at the circumferential connection of the two lining blocks at the tunnel arch waist. Tension in the ring; the longitudinal connection of the lining ring 1 is connected by steel cables. The lining is provided with longitudinal connection holes at certain angles from the vault. The longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com