MEMS gyroscope

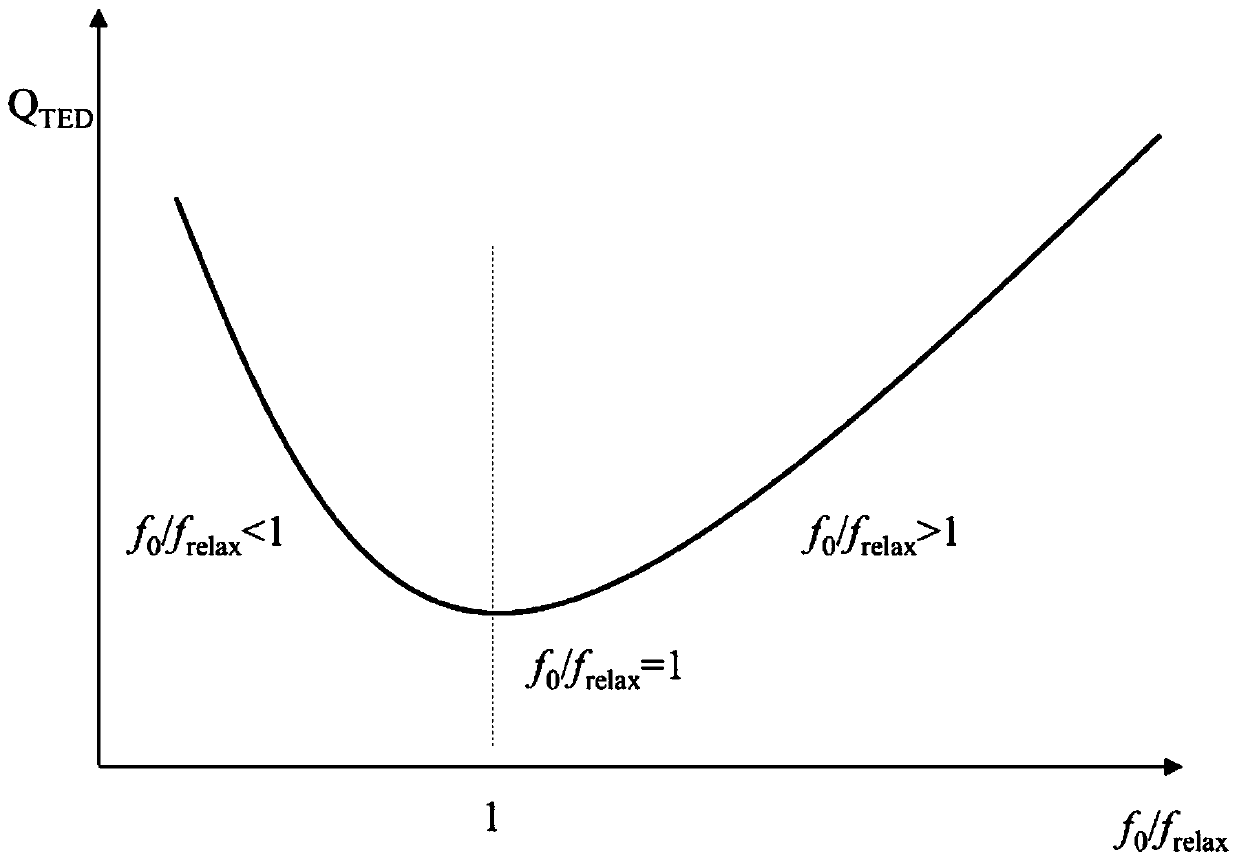

A gyroscope and spiral technology, applied in the field of MEMS gyroscope, can solve the problems of small space layout and low quality factor of disc-shaped gyroscope, and achieve the effects of degenerate mode shape, easy micro-nano processing, and large quality factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

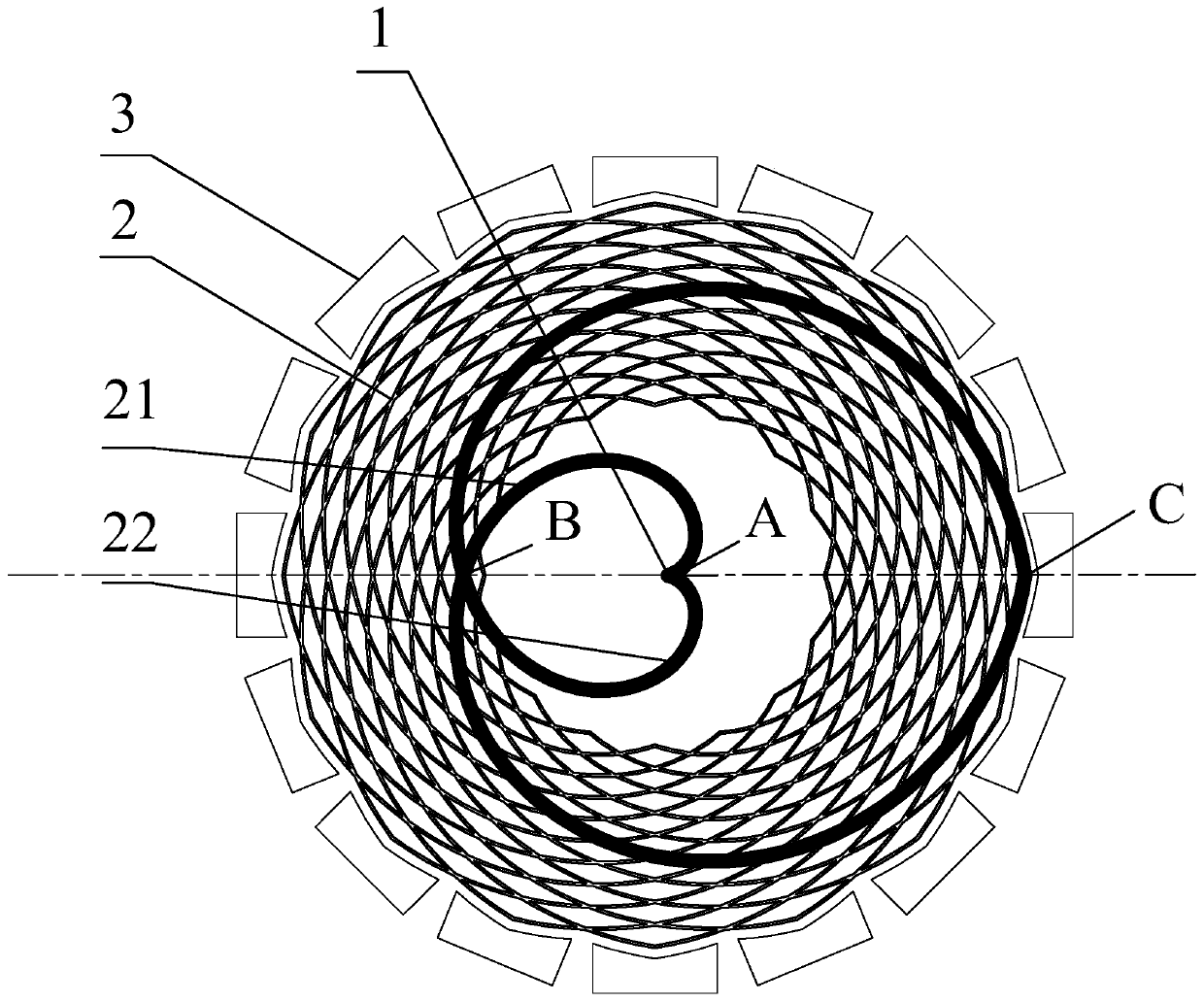

[0040] Implement 1, such as Figure 2-4 Said:

[0041] A MEMS gyroscope in this embodiment includes a resonator and 16 external electrodes 3, and the external electrodes 3 are distributed in a circular array on the periphery of the resonator 6, and the resonator is an axisymmetric disk-shaped network structure, so The harmonic oscillator includes an anchor point structure 1 located in the center of the harmonic oscillator and a helix structure, the helix structure is fixedly connected to the anchor point, the helix structure is composed of 16 helix units in a circular array according to the starting point, each helix A line unit corresponds to one external electrode 3 .

[0042] refer to figure 2, the helical structure is a helical network structure 2 formed by interweaving a plurality of helical unit circular arrays, the first helixes 21 of two adjacent helical units are parallel and equal in length, and the helical network structure also includes A parallelogram hole com...

Embodiment 2

[0046] Implement 2, such as figure 2 and Figure 5 Said:

[0047] The structure of this embodiment is substantially the same as that of Embodiment 1, except that: a spoke structure 4 is arranged in the hole formed by the intersection of the helix structure 2, and the spoke structure 4 is located at the acute angle part of the hole and forms the acute angle. The adjacent two sides of each are connected; specifically, the spoke structure 4 is located at the acute angles on the left and right sides of the parallelogram hole, and the spoke structure 4 is straight beam-shaped. After adding the spoke structure 4, the hole structure of the parallelogram is both Obtuse-angled hexagons, other deformation improvements made to the spoke structure 4 to transform holes with acute-angled structures into holes with obtuse-angled structures all belong to the protection scope of the present invention. The spoke structure 4 can reduce the difficulty of micro-nano processing, weaken the influ...

Embodiment 3

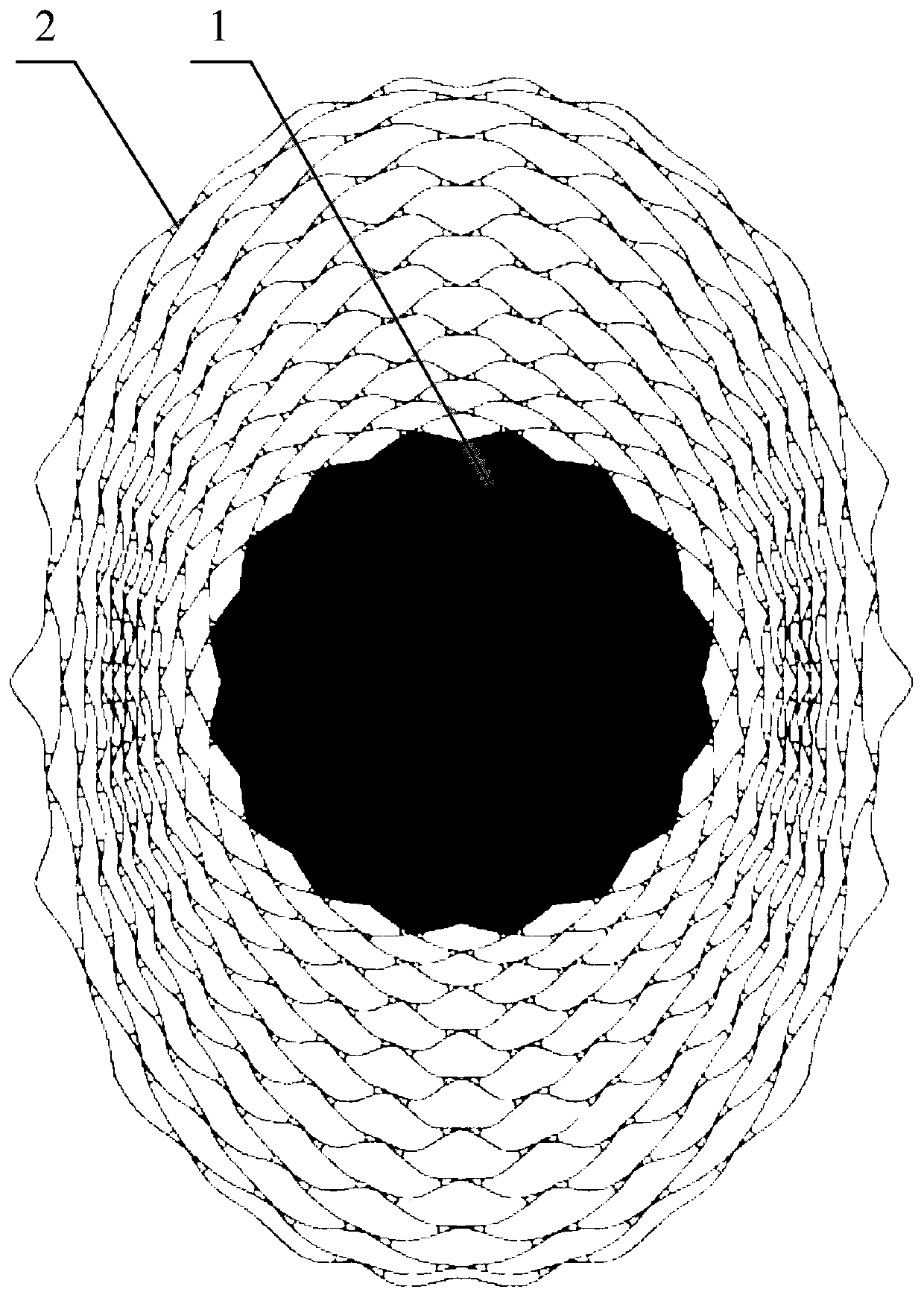

[0048] Implement 3, such as Figure 6-9 Said:

[0049] The helix structure proposed in this embodiment is a honeycomb helix structure 5, and the honeycomb helix structure 5 is formed by deformation treatment of the helix network structure 2, and the deformation treatment includes using a connecting beam 52 to connect the helix along the radial direction of the anchor point structure. The nodes of the network structure 2 and the helical lines intersecting between the adjacent connecting beams 52 in the circumferential direction are removed, thereby forming a honeycomb-shaped subunit surrounded by the left and right connecting beams 52 and the upper and lower helical line units, and the honeycomb-shaped subunits include helical lines And the connecting beam 52 extending radially along the anchor point structure, the hole is formed by connecting the connecting beam 52 and the helix end-to-end to form a hexagonal structure, the connecting beam 52 is a straight beam, the There are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com