Apparatus and method for treatment of process vapours coming from vacuum concentration section of urea plant

A technology of vacuum concentration and urea equipment, applied in the direction of vacuum distillation, chemical instruments and methods, separation methods, etc., to achieve the effect of reducing the flow rate and reducing the total intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

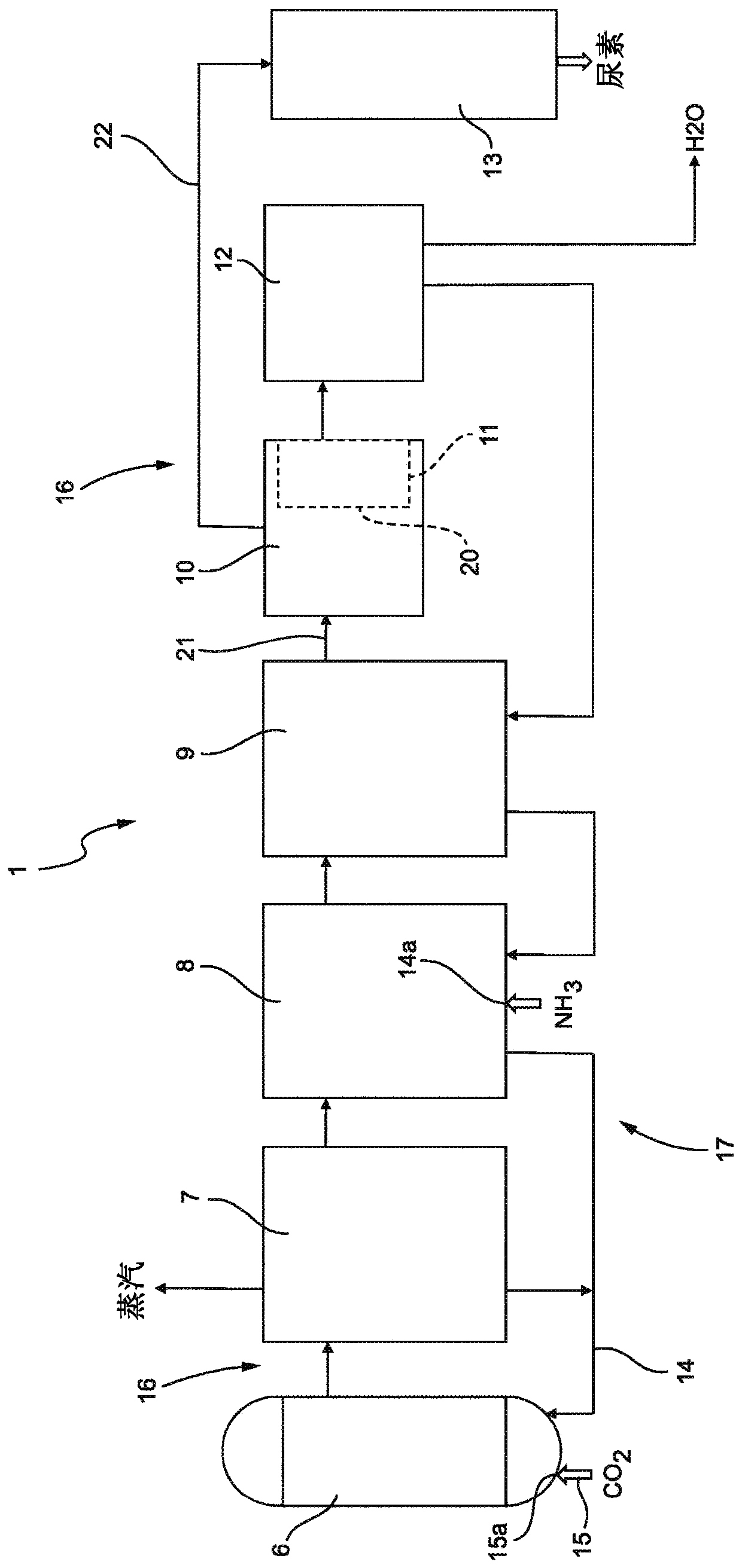

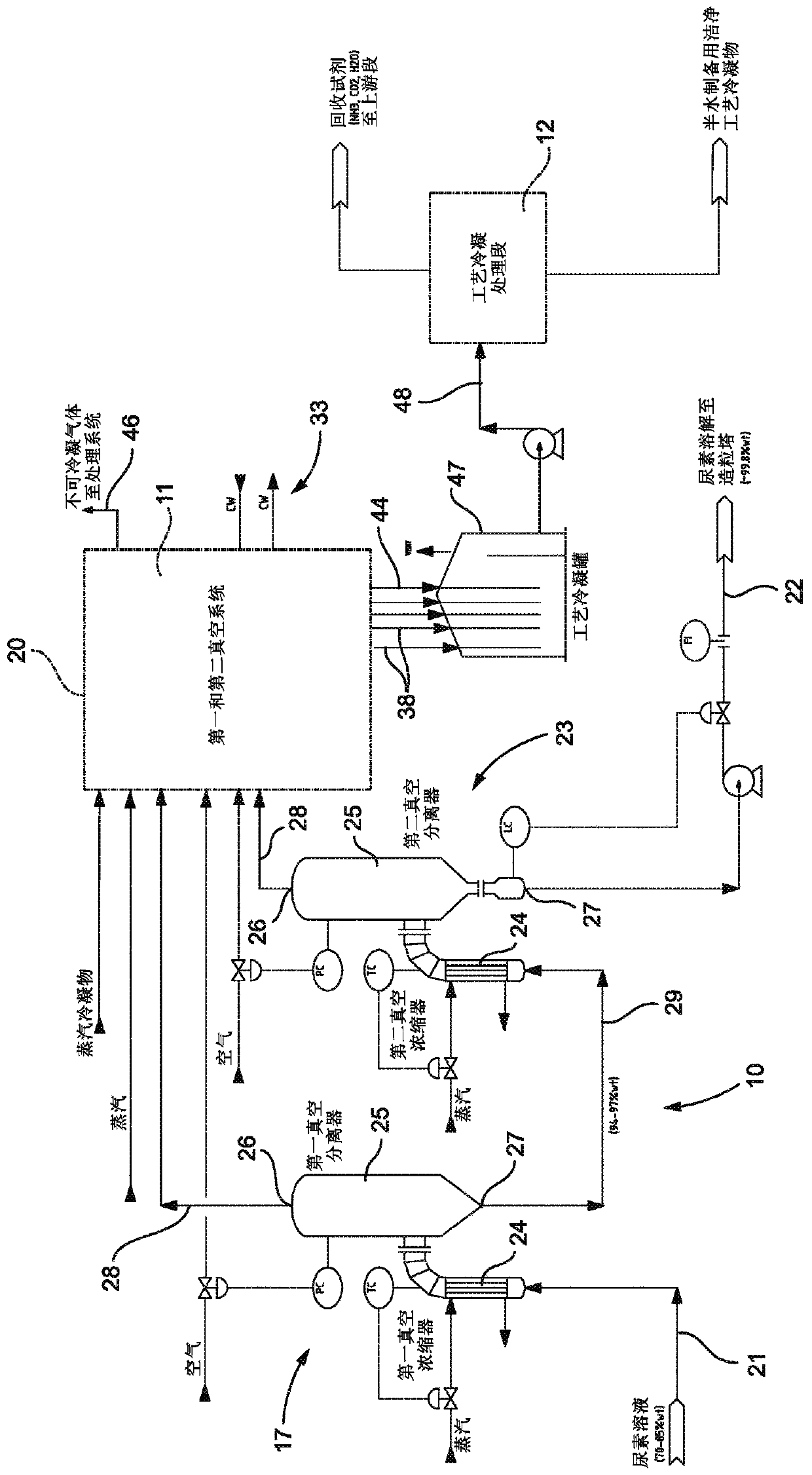

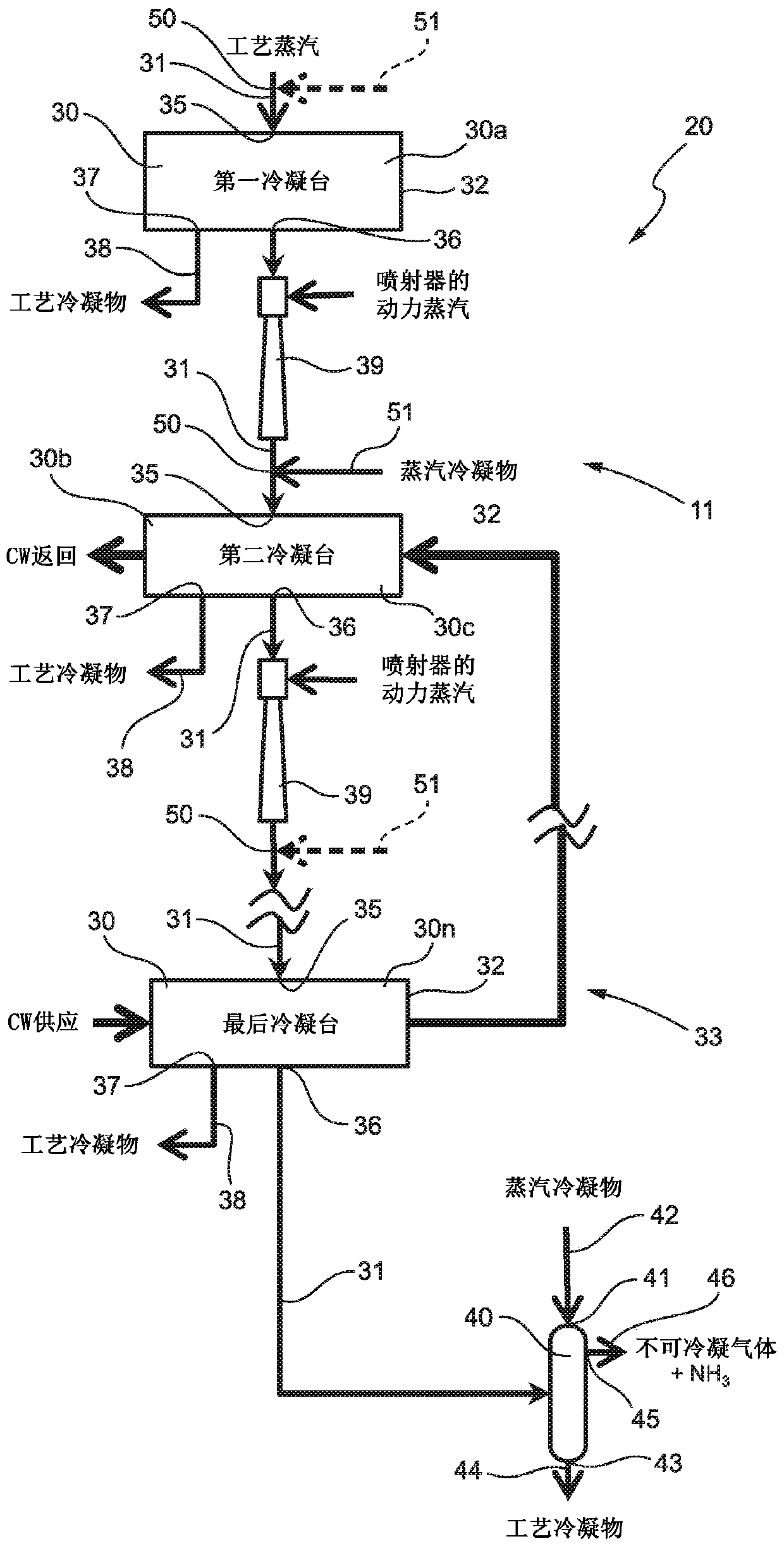

[0055] figure 1 A urea plant 1 (ie a plant for producing urea) is shown in a very schematic way.

[0056] The overall configuration of the urea plant 1 can be of one of several types, as is the urea production process implemented in the plant.

[0057] Here, reference is made by way of example only to a urea production plant / process according to the known "Snamprogetti" technology. It should be understood that the invention is also applicable to other urea production plants / processes using a vacuum concentration section or in any case at least one vacuum system.

[0058] In the non-limiting configuration shown, the urea plant 1 includes, but is not limited to: a urea synthesis reactor 6, in which the urea synthesis reaction from ammonia and carbon dioxide takes place; recovery sections 7, 8 and 9, in particular high pressure recovery section 7, Medium-pressure recovery section 8 and low-pressure recovery section 9, in which the urea solution produced in reactor 6 is graduall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com