Fat function mixture for replacing antibiotic growth promoting agent for livestock and preparation method of fat function mixture

A growth-promoting agent and antibiotic technology, which is applied in the field of feed additives, can solve problems such as easy oxidation, difficult preservation, and poor antibacterial effect, and achieve the effects of improving and repairing the intestinal tract, improving growth performance, and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

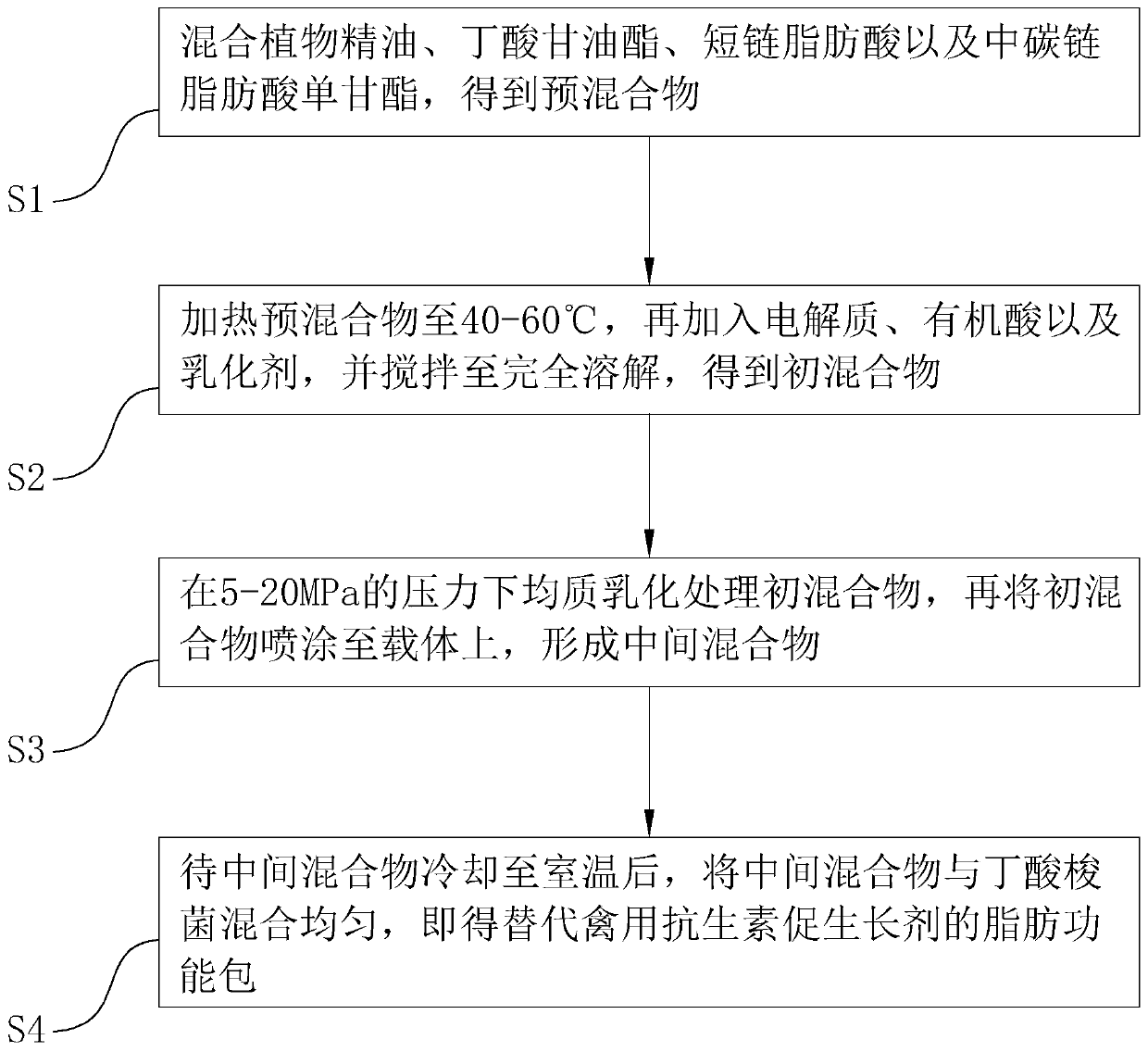

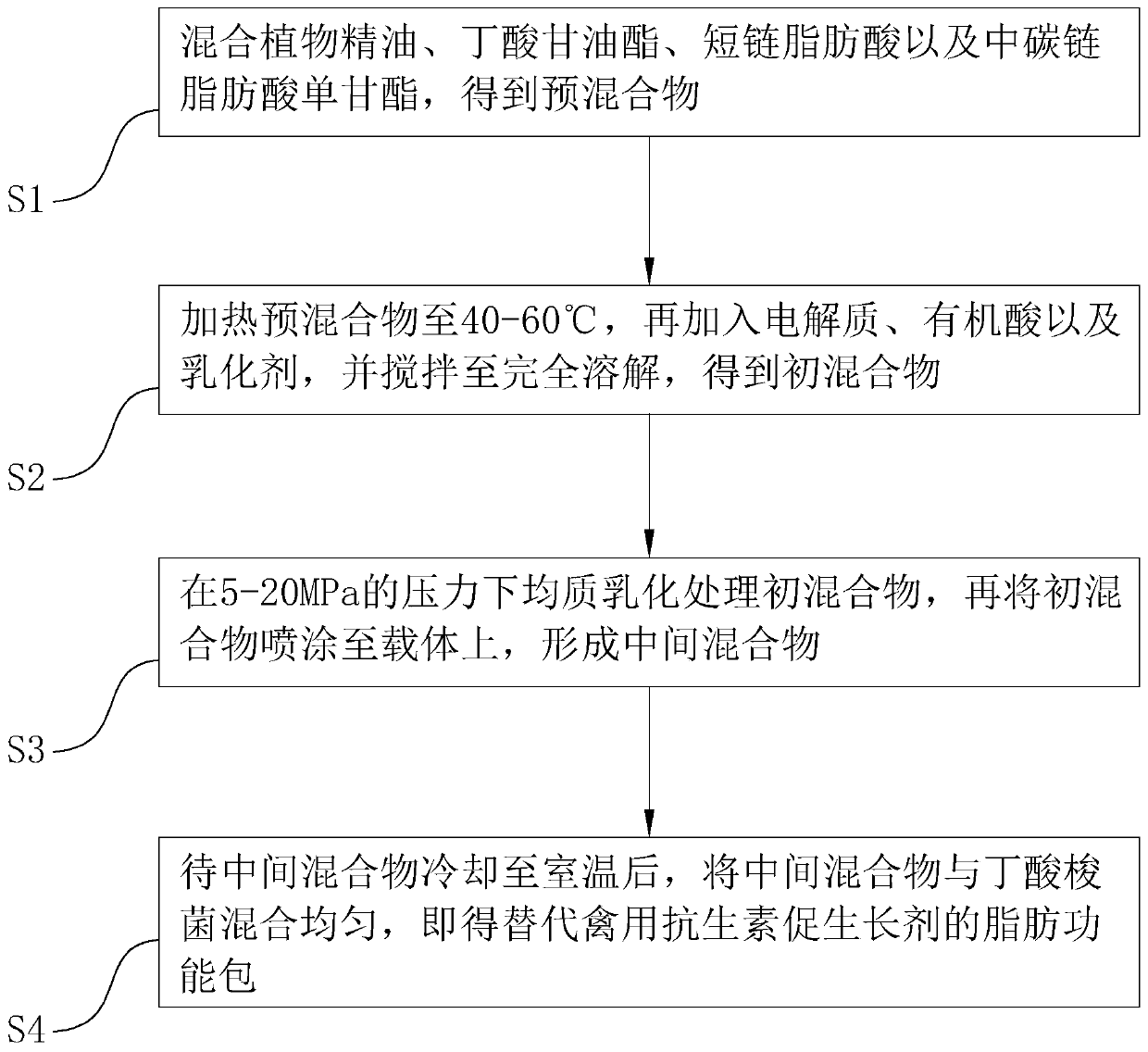

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a fat functional package that replaces antibiotic growth promoters for poultry, comprising the following steps: S1, adding 6.5kg of plant essential oils, 20kg of butyrin, 15kg of short-chain fatty acids, and medium-carbon chain fatty acid monosodium glutamate into a 200L stirred tank Glyceride 5kg was stirred at a speed of 250r / min, and the mixture was evenly stirred to obtain a premixture. S2. Heat the premixture to 40°C, then add 20kg of electrolyte, 11kg of organic acid and 100g of emulsifier while stirring, and stir until completely dissolved to obtain the preliminary mixture. S3. Homogeneously emulsify the initial mixture under a pressure of 5MPa, and then spray the initial mixture onto the carrier 65kg after vacuuming by spraying equipment, and control the spraying pressure to 0.5MPa and the spray speed to 0.5L / min to form an intermediate mixture. S4. After the intermediate mixture is cooled to room temperature, the intermediate mixture is u...

Embodiment 2

[0038] A method for preparing a fat functional package that replaces antibiotic growth promoters for poultry, comprising the following steps: S1, adding 12kg of plant essential oils, 45kg of glyceryl butyrate, 25kg of short-chain fatty acids and medium-carbon chain fatty acid monoglycerides into a 200L stirred tank 12.5 kg of the ester was stirred at a speed of 250 r / min, and the mixture was uniformly stirred to obtain a premixture. S2. Heat the premixture to 50°C, then add 5kg of electrolyte, 1kg of organic acid and 100g of emulsifier while stirring, and stir until completely dissolved to obtain the preliminary mixture. S3. Homogeneously emulsify the initial mixture under a pressure of 13MPa, and then spray the initial mixture onto the carrier 35kg after vacuuming by spraying equipment, and control the spraying pressure to 0.5MPa and the spray speed to 0.5L / min to form an intermediate mixture. S4. After the intermediate mixture is cooled to room temperature, mix the intermedi...

Embodiment 3

[0041] A method for preparing a fat functional package replacing antibiotic growth promoters for poultry, comprising the following steps: S1, adding 1 kg of plant essential oil, 32.5 kg of glyceryl butyrate, 5 kg of short-chain fatty acids and medium-chain fatty acid monosodium glutamate into a 200L stirred tank Glyceride 20kg was stirred at a speed of 250r / min, and the mixture was evenly stirred to obtain a premixture. S2. Heat the premixture to 60°C, then add 12.5kg of electrolyte, 6kg of organic acid and 100g of emulsifier while stirring, and stir until completely dissolved to obtain the preliminary mixture. S3. Homogeneously emulsify the initial mixture under a pressure of 20MPa, and then spray the initial mixture onto a carrier of 50kg after vacuuming with a spraying equipment, and control the spraying pressure to 0.5MPa and the spraying speed to 0.5L / min to form an intermediate mixture. S4. After the intermediate mixture is cooled to room temperature, the intermediate mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective viable count | aaaaa | aaaaa |

| Effective viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com