Method for preparing carbon paper of gas diffusion layer of fuel cell by calendaring and carbon paper

A gas diffusion layer and fuel cell technology, applied in fuel cells, electrical components, battery electrodes, etc., can solve problems such as low porosity, and achieve the effects of high porosity, large pore volume, excellent conductivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

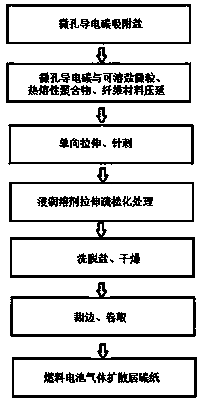

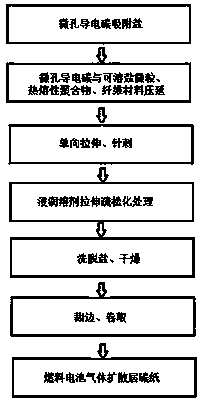

Method used

Image

Examples

Embodiment 1

[0037] (1) Immerse the microporous conductive carbon in a saturated salt solution for 1.5 hours, so that the microporous conductive carbon fully absorbs the salt solution, then filter out the excess liquid salt solution, and dry it so that the salt occupies the gaps in the microporous conductive carbon to obtain the pre- The treated microporous conductive carbon; the microporous conductive carbon is conductive carbon black with micropores; the saturated salt solution is a saturated solution composed of sodium chloride and ammonium sulfate;

[0038] (2) Disperse the pretreated microporous conductive carbon with soluble salt particles, hot-melt polymers, and fiber materials evenly, then add the mixed materials into the mixer for thermal mixing, and then calender through the calender, one-way Stretching, and finally needling roller treatment, to obtain a thin sheet with through micropores and an average thickness of 0.26mm; the soluble salt particles are sodium chloride particles;...

Embodiment 2

[0043] (1) Immerse the microporous conductive carbon in a saturated salt solution for 1 hour, so that the microporous conductive carbon fully absorbs the salt solution, then filter out the excess liquid salt solution, and dry it so that the salt occupies the gaps in the microporous conductive carbon to obtain pretreatment The microporous conductive carbon; the microporous conductive carbon is a graphene airgel with micropores; the saturated salt solution is a saturated solution composed of sodium chloride and ammonium phosphate;

[0044] (2) Disperse the pretreated microporous conductive carbon with soluble salt particles, hot-melt polymers, and fiber materials evenly, then add the mixed materials into the mixer for thermal mixing, and then calender through the calender, one-way Stretching, and finally needling roller treatment, to obtain a thin sheet with through pores and an average thickness of 0.2mm; the soluble salt particles are sodium sulfate particles; the hot-melt poly...

Embodiment 3

[0048] (1) Immerse the microporous conductive carbon in a saturated salt solution for 2 hours, so that the microporous conductive carbon fully absorbs the salt solution, then filter out the excess liquid salt solution, and dry it so that the salt occupies the gaps in the microporous conductive carbon to obtain pretreatment The microporous conductive carbon; the microporous conductive carbon is a carbon fiber ball with micropores; the saturated salt solution is a saturated solution of sodium sulfate and ammonium sulfate;

[0049] (2) Disperse the pretreated microporous conductive carbon with soluble salt particles, hot-melt polymers, and fiber materials evenly, then add the mixed materials into the mixer for thermal mixing, and then calender through the calender, one-way Stretching, and finally needling roller treatment, to obtain a thin sheet with through pores and an average thickness of 0.3mm; the soluble salt particles are sodium chloride particles; the hot-melt polymer is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com