Method for maintaining a sterile atmosphere in a bottling unit

A bottling and atmosphere technology, applied in the field of beverage filling and sealing, can solve the problems of low reliability of the system and the inability of the valve to last, and achieve the effects of ensuring sterility, simplifying design and effectively utilizing space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

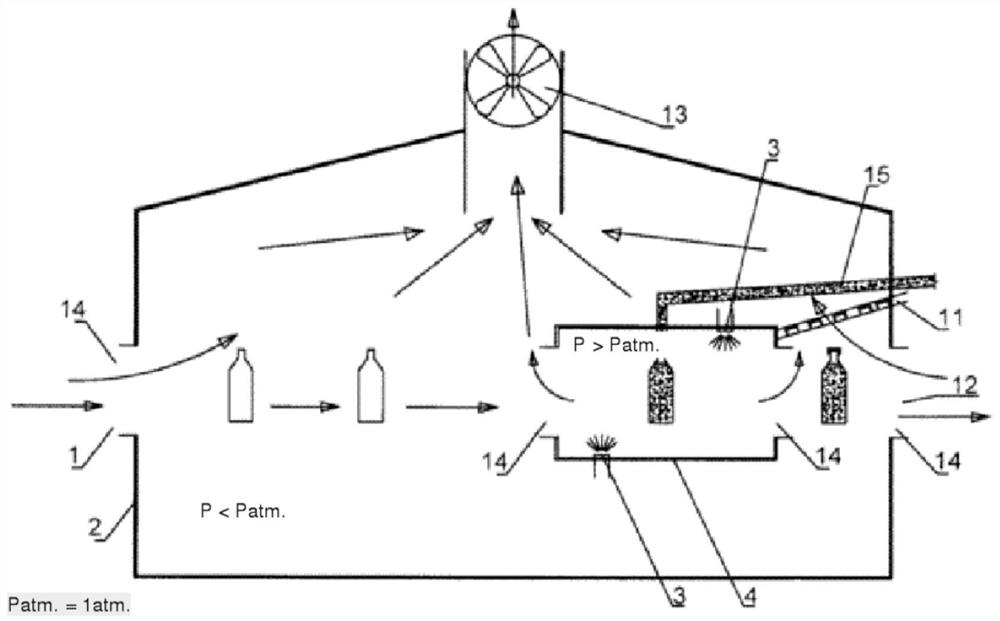

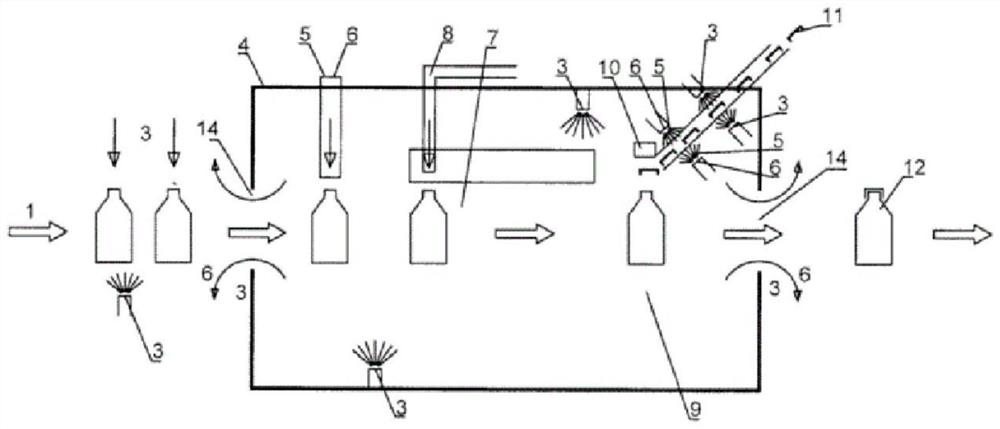

[0056] Explanation of the proposed method:

[0057] The sterilizing mixture 3 and sterile air 6 generate an elevated pressure, while the airflow generated by the variable speed exhaust fan 13 generates a reduced pressure.

[0058] Before the filling process, that is to say before feeding the bottles 1 and caps 11 into the non-pressurized isolator 4, the first step is to decontaminate the isolator. A sterilizing mixture 3 of peroxide and air is continuously fed into the space of the internal circuit 4 for 5 minutes, thus ensuring the microbiological purity and thus preparing it for the main process.

[0059] Before entering the non-pressurized isolator 4 , the empty bottle 1 is treated externally and internally with a sterilizing mixture 3 . Mixture 3 settles on the wall of bottle 1 to completely purify bottle 1.

[0060] The bottles 1 enter the non-pressurized isolator 4 to first pass through a purge zone 5 with sterile hot air 6 . As a result, residual peroxide is removed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com