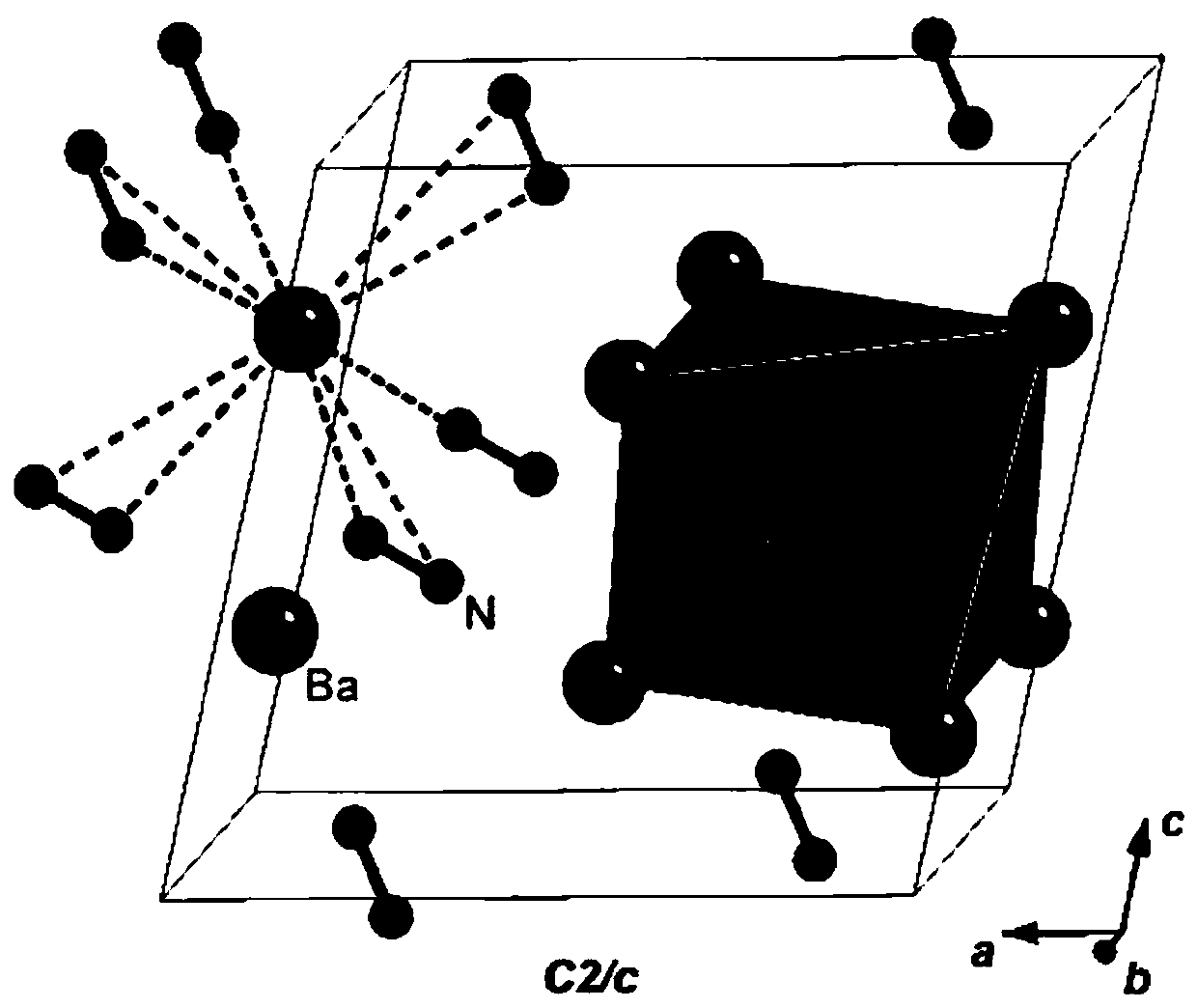

High-temperature and high-pressure preparation method of monoclinic-phase barium diazene

A technology of phase diazene, high temperature and high pressure, applied in the field of preparation of monoclinic barium diazene, to achieve the effect of shortening the preparation time, realizing large-scale production and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

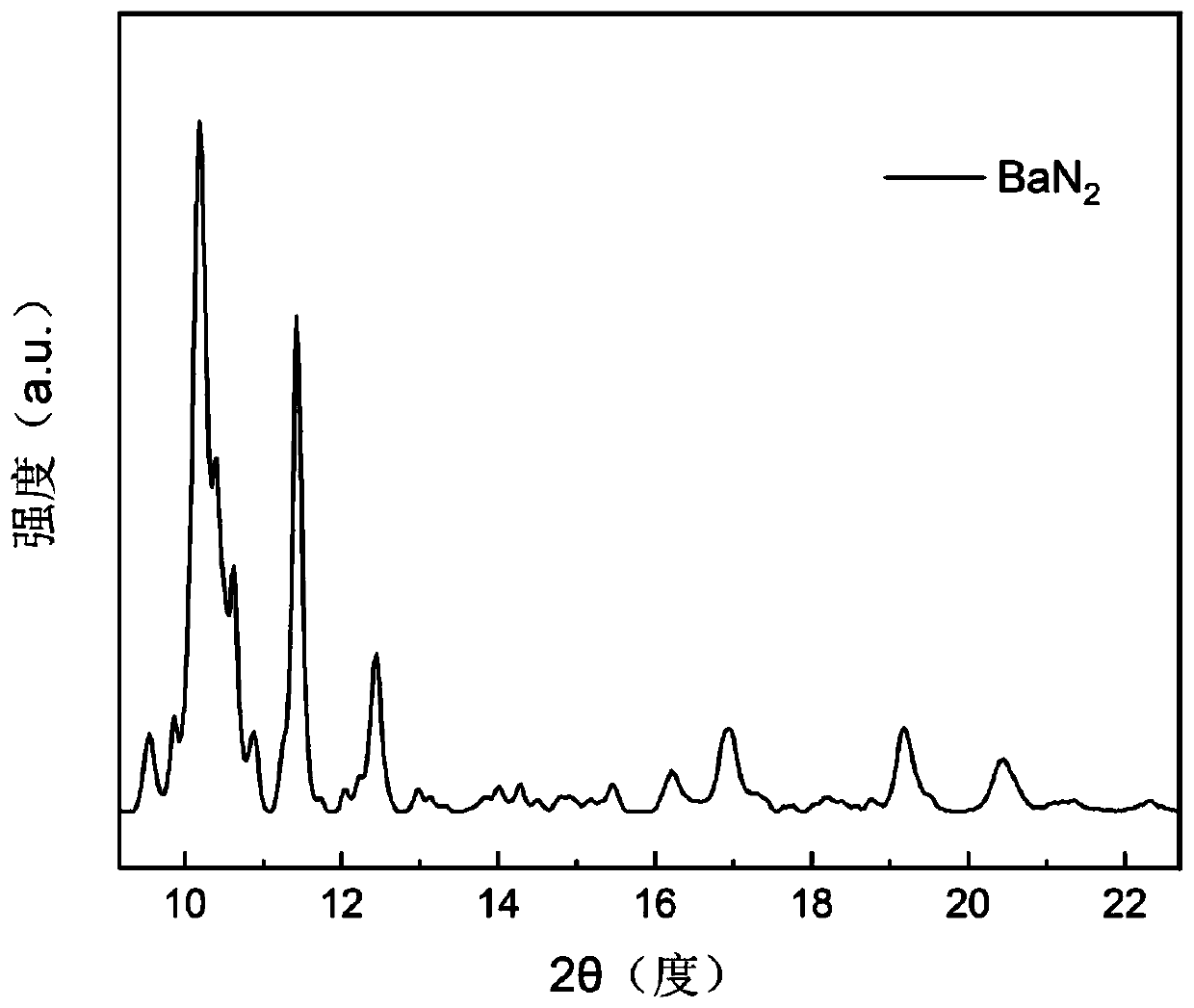

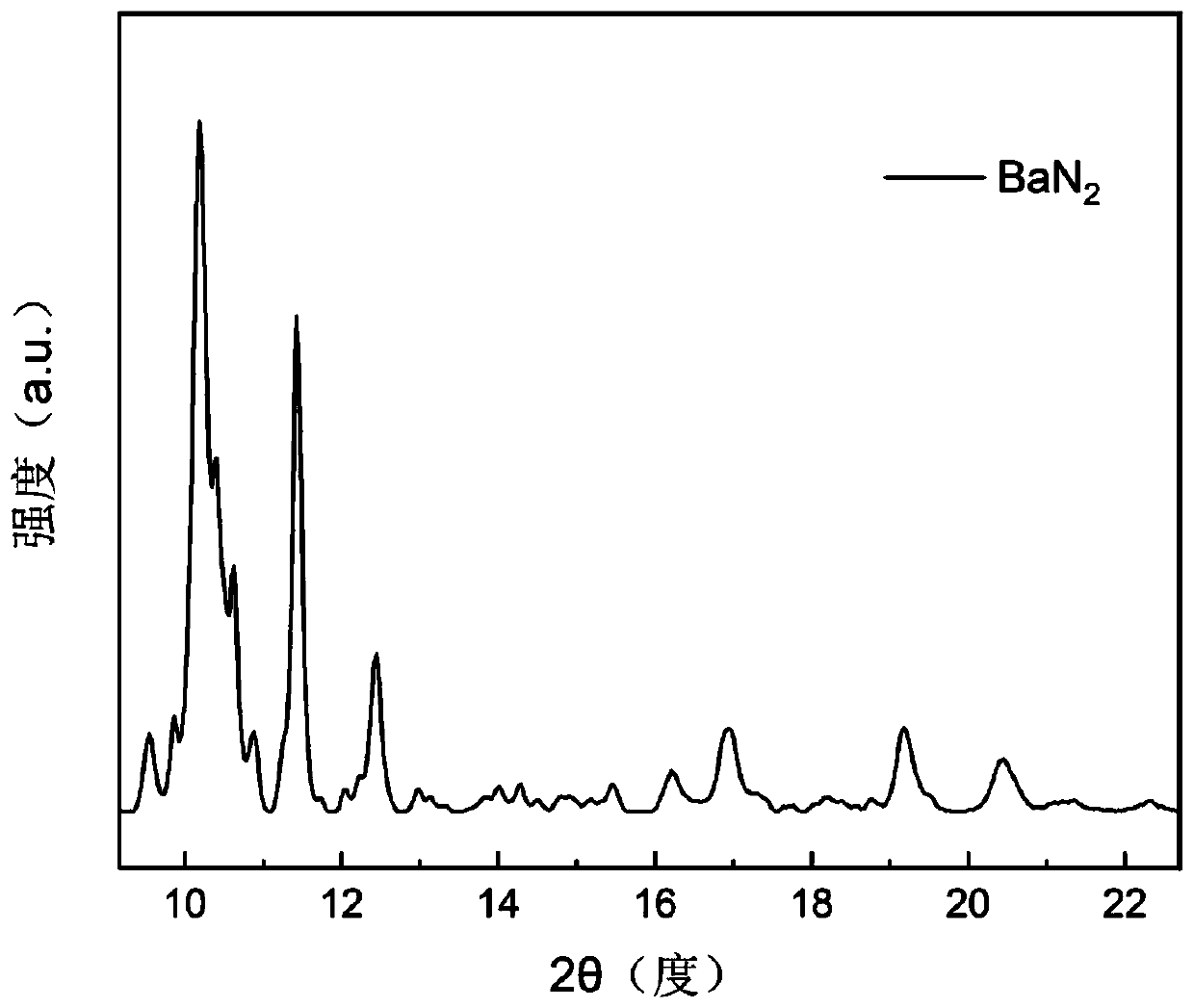

[0018] Using barium azide (Ba(N 3 ) 2 ) as the raw material, first grind and briquetting, gently grind the barium azide block into powder with an agate mortar, and use a small hydraulic press to press the barium azide powder into a cylindrical shape according to the size of the synthesis cavity (height 2.5mm and 4.0mm in diameter); then start to assemble, wrap the pressed barium azide in the glove box, wrap the hexagonal boron nitride tube, then put it into the graphite tube heating container, and finally put it into the synthesis chamber Then carry out the high temperature and high pressure preparation process, adopt the domestic SPD6×600 type six-sided top press as the equipment providing high temperature and high pressure synthesis conditions, the synthesis pressure is 3GPa, and the synthesis temperature is 720K. Under this condition, the pressure is kept for 15 minutes, and then stop After heating, the sample began to cool down to room temperature naturally and then the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com