Modified isocyanate emulsion cross-linking agent, modified adhesive and application

An isocyanate and emulsion cross-linking technology, applied in the direction of adhesive additives, polyurea/polyurethane adhesives, polymer adhesive additives, etc., can solve problems such as uneven dispersion, complicated process, and stress concentration of the adhesive layer, and achieve Good pre-pressing performance, simple and easy process, high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077]

[0078] The present embodiment also provides the preparation method of this modified isocyanate emulsion crosslinking agent, as follows:

[0079] 1. Add 4 kg of tannic acid into 7 kg of water and stir for 6 minutes until uniformly mixed to obtain an aqueous solution of tannic acid;

[0080] 2. Add the prepared tannic acid aqueous solution into 20 kg of pMDI and directly emulsify for 10 minutes to obtain a uniform modified isocyanate emulsion crosslinking agent.

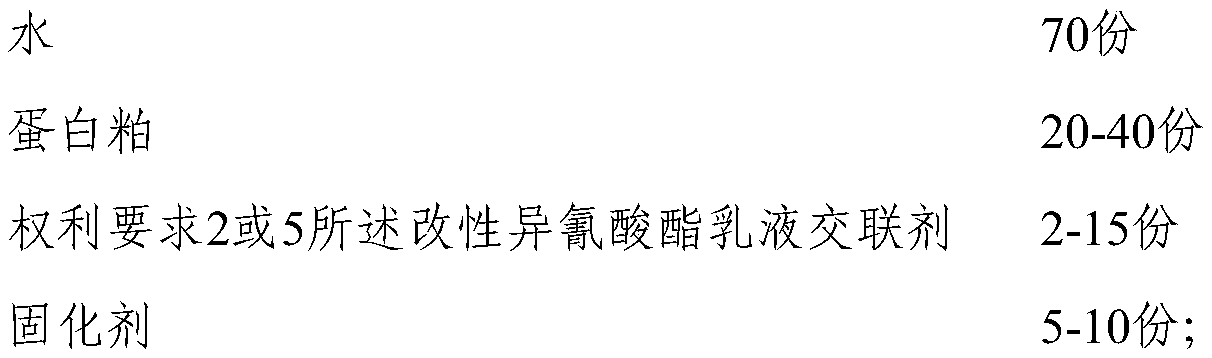

[0081] This embodiment provides a modified vegetable protein adhesive, which is made of the following raw materials in weight ratio:

[0082]

[0083] The present embodiment also provides the preparation method of this modified vegetable protein adhesive, as follows:

[0084] 1. Disperse 25kg of protein meal in 70kg of water, and stir evenly at a speed of 800 rpm to obtain a mixture containing protein meal and water;

[0085] 2. Add 8 kg of the modified isocyanate emulsion cross-linking agent of this e...

Embodiment 2

[0088] This embodiment provides a modified isocyanate emulsion crosslinking agent, which is made of the following raw materials in weight ratio:

[0089]

[0090] The present embodiment also provides the preparation method of this modified isocyanate emulsion crosslinking agent, as follows:

[0091] 1. Add 3.5 kg of tannic acid into 8 kg of water and stir for 5 minutes until uniformly mixed by mechanical stirring to obtain an aqueous solution of tannic acid;

[0092] 2. Add the prepared tannic acid aqueous solution into 20kg of pMDI, and directly emulsify for 8 minutes to obtain a uniform modified isocyanate emulsion crosslinking agent.

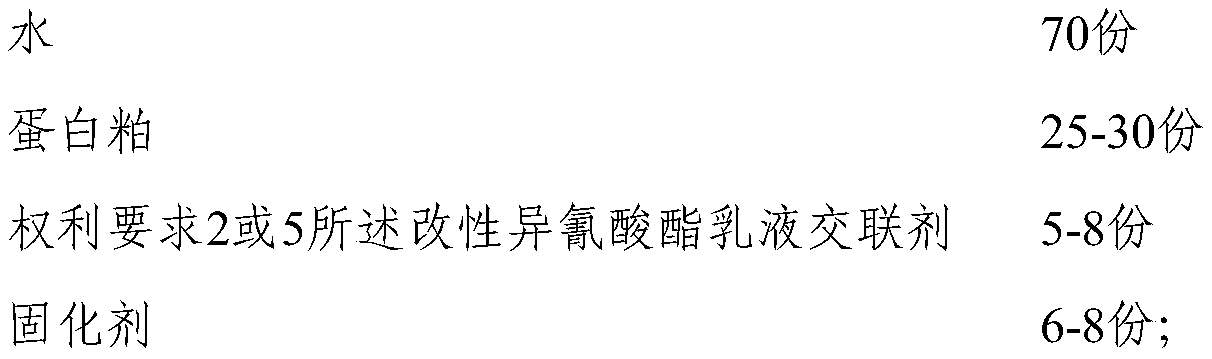

[0093] This embodiment provides a modified vegetable protein adhesive, which is made of the following raw materials in weight ratio:

[0094]

[0095] The present embodiment also provides the preparation method of this modified vegetable protein adhesive, as follows:

[0096] 1. Disperse 28kg of protein meal in 70kg of water, and stir...

Embodiment 3

[0100] This embodiment provides a modified isocyanate emulsion crosslinking agent, which is made of the following raw materials in weight ratio:

[0101]

[0102]

[0103] The present embodiment also provides the preparation method of this modified isocyanate emulsion crosslinking agent, as follows:

[0104] 1. Add 5kg of gallic acid to 7kg of water heated to 60°C and stir for 6 minutes until uniformly mixed to obtain an aqueous solution of gallic acid;

[0105] 2. Add the prepared gallic acid aqueous solution into 20 kg of pMDI and directly emulsify for 15 minutes to obtain a uniform modified isocyanate emulsion crosslinking agent.

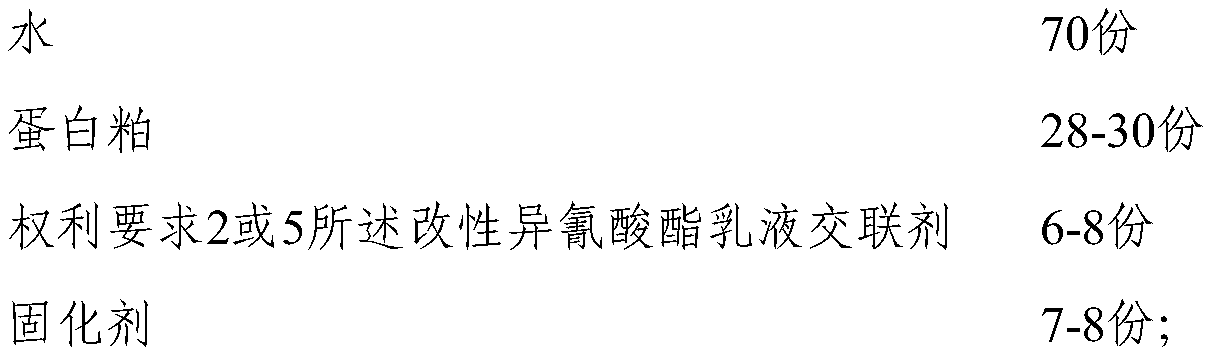

[0106] This embodiment provides a modified vegetable protein adhesive, which is made of the following raw materials in weight ratio:

[0107]

[0108] The present embodiment also provides the preparation method of this modified vegetable protein adhesive, as follows:

[0109] 1. Disperse 30kg of protein meal in 70kg of water, and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com