Polysiloxane-based polyurethane/lignin elastomer as well as preparation method and application thereof

A polysiloxane-based, polysiloxane technology, which is applied in the field of polysiloxane-based polyurethane/lignin elastomer and its preparation, can solve the problems that have not yet been seen, reduce the mechanical strength of materials, and reduce the polysiloxane phase. Poor tolerance and other problems, to achieve the effect of rich raw materials, good hydrophobicity, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

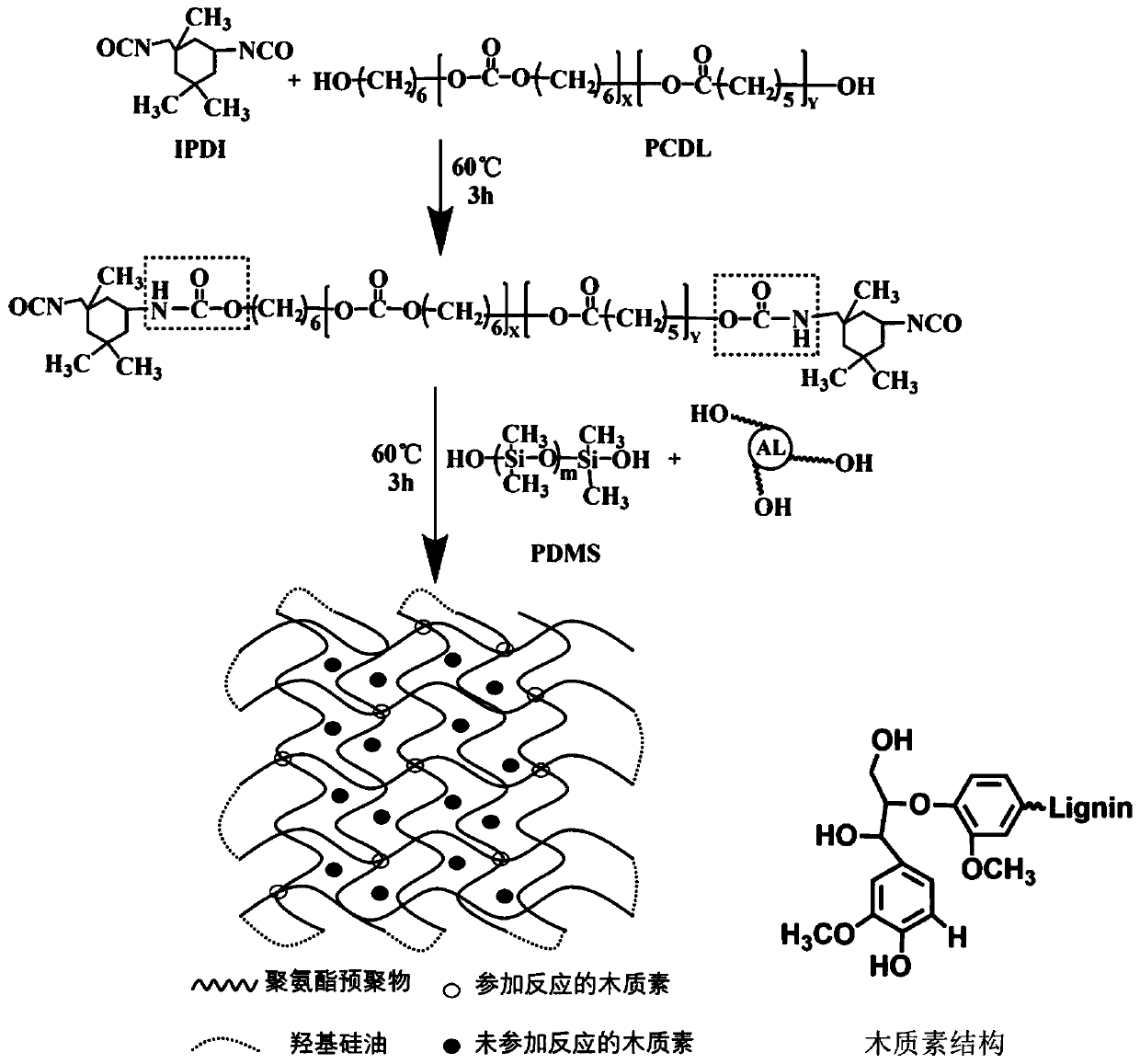

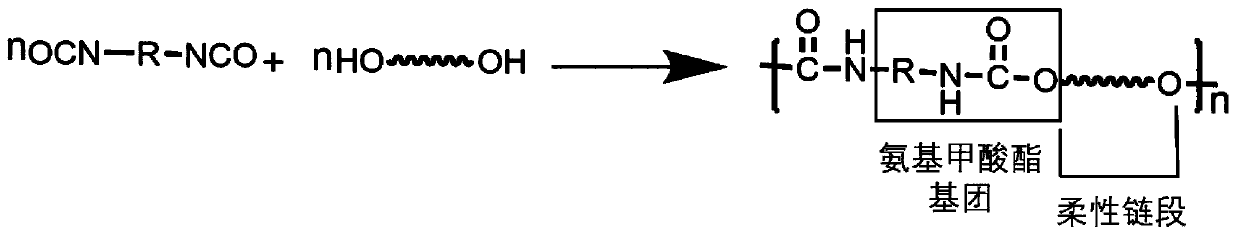

[0055] (1) Preparation of polysiloxane-based polyurethane / lignin solution

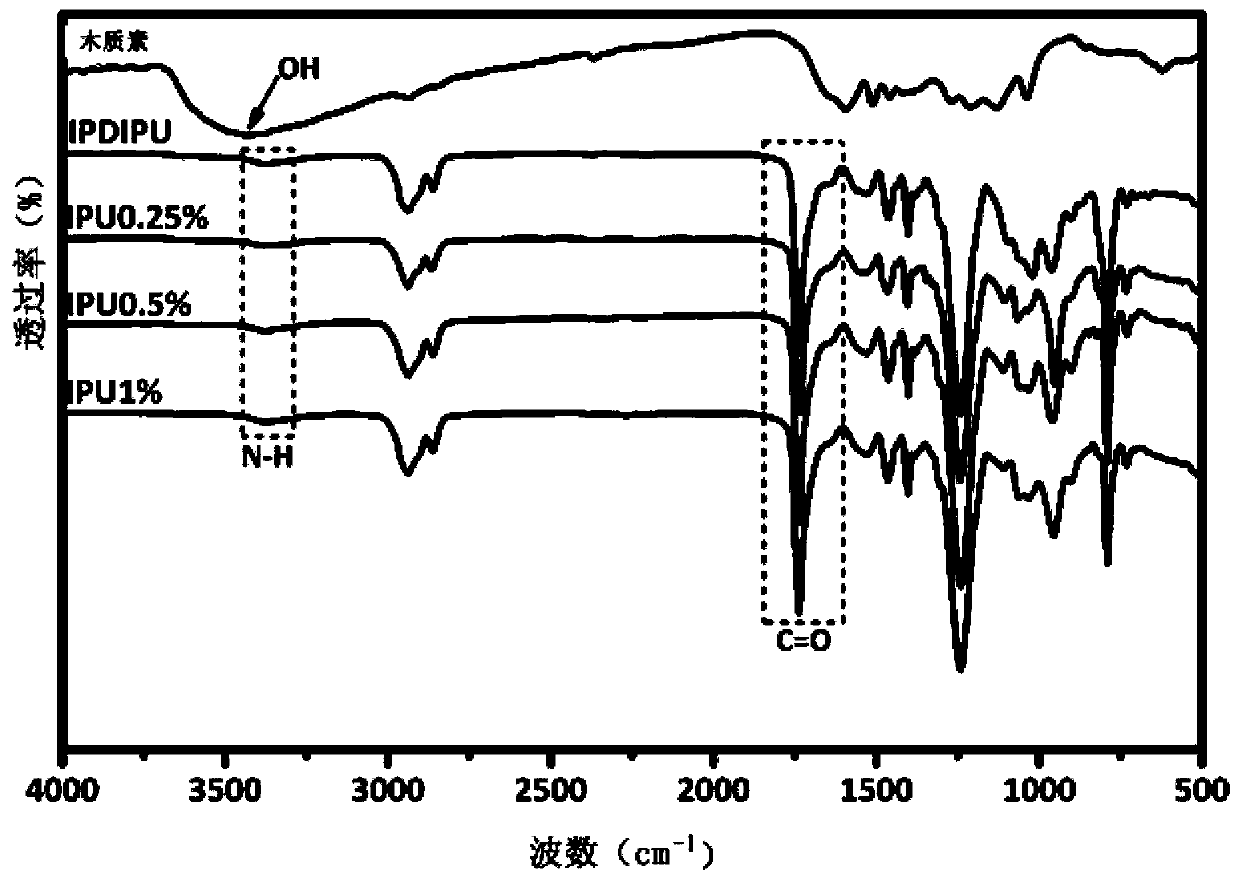

[0056] Mix 1.17g isophorone diisocyanate (IPDI) and dibutyltin dilaurate catalyst (catalyst addition is 2-3 drops), 20mL N,N-dimethylformamide (DMF) and 5g polycarbonate diol (PCDL) was added into a 250mL three-necked flask, the temperature was raised to 60°C, and the mechanical stirrer was stirred at a speed of 500rpm, and the reaction was carried out for 3h to obtain a prepolymer mixed solution; then 1.25g of hydroxyl-capped Terminated polysiloxane was dissolved in 5 mL of DMF, and 0.25% by mass of lignin (the mass fraction of lignin was the percentage of the mass sum of IPDI, PCDL, and PDMS) was added to the above-mentioned PDMS-dissolved solution for ultrasonic treatment for 30 min, and then added The reaction was continued for 3 hours during the reaction. After the reaction, the reaction temperature was lowered to 50° C., and the product (polysiloxane-containing polyurethane / lignin solution contai...

Embodiment 2

[0060] (1) Preparation of polysiloxane-based polyurethane / lignin solution

[0061] Mix 1.17g isophorone diisocyanate (IPDI) and dibutyltin dilaurate catalyst (catalyst addition is 2-3 drops), 20mL N,N-dimethylformamide (DMF) and 5g polycarbonate diol Add it into a 250mL three-necked flask, raise the temperature to 60°C, stir under the action of a mechanical stirrer at a speed of 500rpm, and react for 3h to obtain a prepolymer mixed solution; then add 1.25g of hydroxyl-terminated polysilicon Dissolve oxane in 5 mL of DMF, add 0.5% lignin by mass (the mass fraction of lignin is the percentage of the mass sum of IPDI, PCDL, and PDMS) into the PDMS-dissolved solution for ultrasonic treatment for 30 min, and then add to the reaction to continue After the reaction was completed for 3 hours, the reaction temperature was lowered to 50° C., and the product (polysiloxane-containing polyurethane / lignin solution containing solvent) was removed from the three-necked flask.

[0062] (2) Pr...

Embodiment 3

[0065] (1) Preparation of polysiloxane-based polyurethane / lignin solution

[0066] Mix 1.17g isophorone diisocyanate (IPDI) and dibutyltin dilaurate catalyst (catalyst addition is 2-3 drops), 20mL N,N-dimethylformamide (DMF) and 5g polycarbonate diol Add it into a 250mL three-necked flask, raise the temperature to 60°C, stir under the action of a mechanical stirrer at a speed of 500rpm, and react for 3h to obtain a prepolymer mixed solution; then add 1.25g of hydroxyl-terminated polysilicon Dissolve oxane in 5 mL of DMF, add 1% lignin by mass (the mass fraction of lignin is the percentage of the mass sum of IPDI, PCDL and PDMS) into the PDMS-dissolved solution for ultrasonic treatment for 30 min, and then add to the reaction to continue After the reaction was completed for 3 hours, the reaction temperature was lowered to 50° C., and the product (polysiloxane-containing polyurethane / lignin solution containing solvent) was removed from the three-necked flask.

[0067] (2) Prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com