Zinc oxide nanoparticle stable solution, and zinc oxide-polymer nanocomposite stable solution, preparation method and applications thereof

A nanocomposite material, zinc oxide nanotechnology, applied in the field of material chemistry, to achieve the effect of convenient and efficient removal of stabilizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

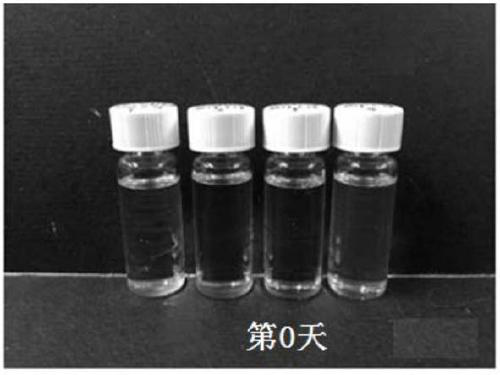

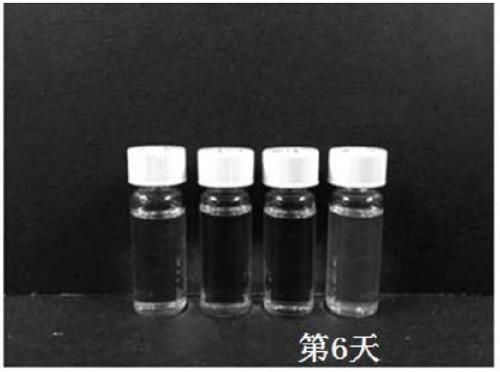

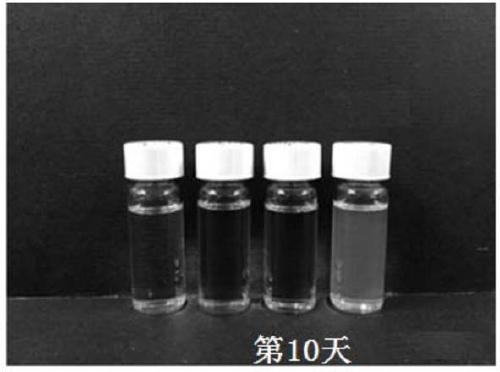

[0063] A zinc oxide-P3HT nanocomposite stable solution was prepared, and a thin film was prepared.

[0064] 1. Prepare zinc oxide nanoparticles stable solution

[0065] Dissolve 100 mg of zinc oxide nanoparticles (dissolved in 1 mL of chlorobenzene, measure 0.1 mL of propylamine into the solution, and dilute to 30 mg / mL with chlorobenzene to obtain a stable solution of zinc oxide nanoparticles.

[0066] 2. Configure P3HT solution

[0067] Dissolve 30mg of P3HT in 1mL of chlorobenzene and stir to dissolve.

[0068] 3. Mix

[0069] The zinc oxide nanoparticle stable solution and the P3HT solution were mixed at a ratio of 1:1 to obtain a zinc oxide-P3HT nanocomposite stable solution.

[0070] 4. Preparation of thin film

[0071] The thin film was prepared by spin-coating the stabilized solution of zinc oxide nanoparticles in this embodiment, and the spin-coating speed was 1000 rpm for 30 s.

Embodiment 2

[0073] A zinc oxide-P3HT nanocomposite stable solution was prepared, and a thin film was prepared.

[0074] 1. Prepare zinc oxide nanoparticles stable solution

[0075] Dissolve zinc oxide nanoparticles (100 mg) in chlorobenzene (1 mL), measure 0.1 mL of butylamine into the solution, and dilute to 30 mg / mL with chlorobenzene to obtain a stable solution of zinc oxide nanoparticles.

[0076] 2. Configure P3HT solution

[0077] Dissolve 30mg of P3HT in 1mL of chlorobenzene and stir to dissolve.

[0078] 3. Mix

[0079] The zinc oxide nanoparticle stabilization solution and the P3HT solution were mixed in a ratio of 1:2 to obtain a zinc oxide-P3HT nanocomposite stabilization solution.

[0080] 4. Preparation of thin film

[0081] The thin film was prepared by spin-coating the stabilized solution of zinc oxide nanoparticles in this embodiment, and the spin-coating speed was 1000 rpm for 30 s.

Embodiment 3

[0083] A zinc oxide-P3HT nanocomposite stable solution was prepared, and a thin film was prepared.

[0084] 1. Prepare zinc oxide nanoparticles stable solution

[0085] Dissolve 100 mg of zinc oxide nanoparticles in 1 mL of chloroform, add 0.1 mL of isobutylamine into the solution, and dilute to 30 mg / mL with chloroform to obtain a stable solution of zinc oxide nanoparticles.

[0086] 2. Configure P3HT solution

[0087] Dissolve 30mg of P3HT in 1mL of chlorobenzene and stir to dissolve.

[0088] 3. Mix

[0089] The zinc oxide nanoparticle stabilization solution and the P3HT solution were mixed in a ratio of 1:1 to obtain a zinc oxide-P3HT nanocomposite stabilization solution.

[0090] 4. Preparation of thin film

[0091] The thin film was prepared by spin-coating the stabilized solution of zinc oxide nanoparticles in this embodiment, and the spin-coating speed was 1000 rpm for 30 s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com