Toxoflavin high-producing strain and application thereof

A high-yield technology of toxoflavin, applied in the field of microorganisms, can solve the problem of low toxoflavin production and achieve the effect of stabilizing toxoflavin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1. Extraction of toxigenic flavin from solid culture of Burkholderia sp.HDXY-02

[0030] 1. Activation of strains

[0031] Pick the preserved Burkholderia sp.HDXY-02 strain, streak on the seed solid medium (0.5% beef extract; 1% peptone; 0.5% NaCl; 2% agar; distilled water; pH7.0), 30-35 ° C, Cultivate at constant temperature for 48-72 hours.

[0032] 2. Solid plate culture

[0033] Pick a single colony of Burkholderia sp.HDXY-02 and inoculate it on the seed medium (0.5% beef extract; 1% peptone; 0.5% NaCl; 2% agar; distilled water; pH7.0) and shake it for 24 hours. KMB medium (peptone 20.0g, dipotassium hydrogen phosphate 1.5g, magnesium sulfate 0.75g, glycerol 15mL, pH 5.5-8.5, constant volume to 1000mL, 1.5% agar), 30-35℃, static culture at constant temperature for 48-72h .

[0034] 3. Extraction of Toflavin

[0035] Scrape off the bacterial lawn on the surface of the solid medium, chop the solid medium rich in toxin flavin, add 1 / 2 volume of chloroform ...

Embodiment 2

[0036] Example two. Burkholderia sp.HDXY-02 liquid fermentation toxaflavin production

[0037] 1. Activation of strains

[0038]Pick the preserved Burkholderia sp.HDXY-02 strain, streak on the seed solid medium (0.5% beef extract; 1% peptone; 0.5% NaCl; 2% agar; distilled water; pH7.0), 30-35 ° C, Cultivate at constant temperature for 48-72 hours.

[0039] 2. Liquid fermentation process

[0040] Pick the Burkholderia sp.HDXY-02 strain on the seed medium and dilute it with normal saline and mix it evenly. Draw 1-10mL overnight culture and inoculate it into 100mL KMB liquid medium (peptone 20.0g, dipotassium hydrogen phosphate 1.5g, sulfuric acid Magnesium 0.75g, glycerin 15mL, pH 5.5-8.5, constant volume to 1000mL) in a 250mL Erlenmeyer flask, 30-35°C, 150-200rpm, continuous shaking culture for 48-72h.

[0041] 3. Extraction of Toflavin

[0042] After shaking culture, centrifuge the fermentation broth at 4-20°C, 4000-6000g for 4-5min, absorb the supernatant, add 1 / 2 volume ...

Embodiment 3

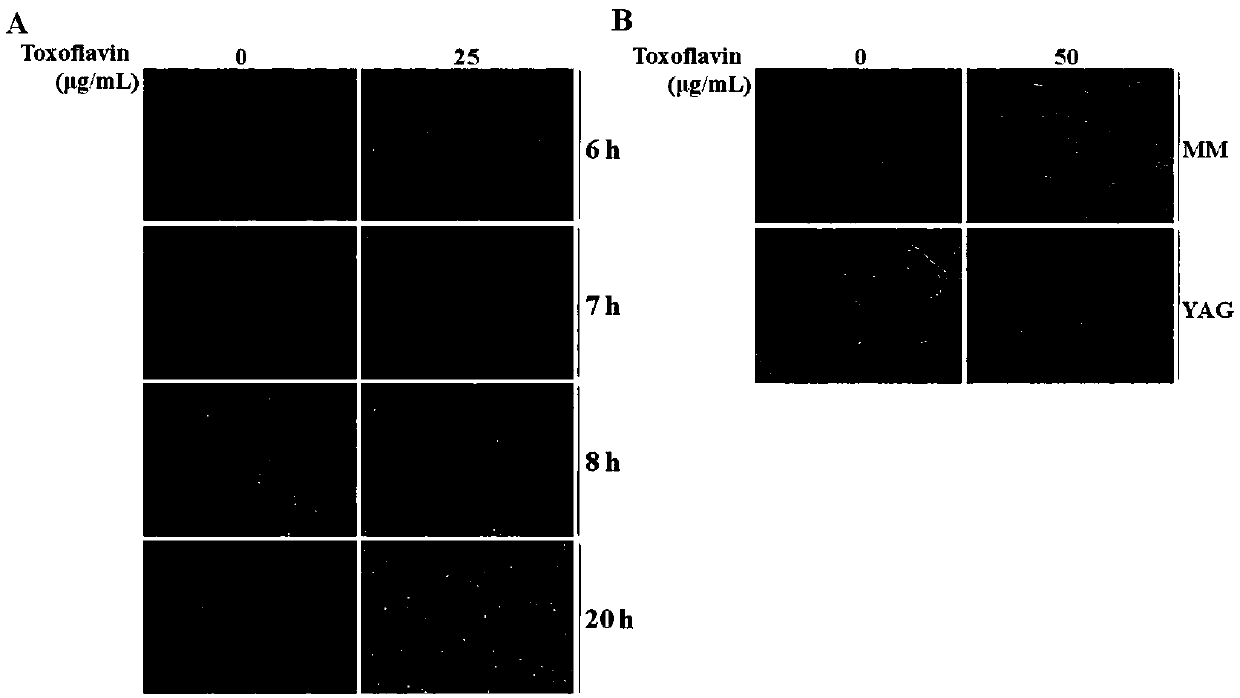

[0043] Example three. Toxoflavin detection

[0044] Secondary purification of toxin: the above crude extract is separated and purified by silica gel column chromatography, and the gradient elution process is: (dichloromethane: methanol) 90:10→80:20→60:40→50:50 →30:70→0:100 (v / v). And further recrystallized twice through n-butanol to obtain the purified toxin.

[0045] The toxin extracted from the strain was compared with the toxin standard.

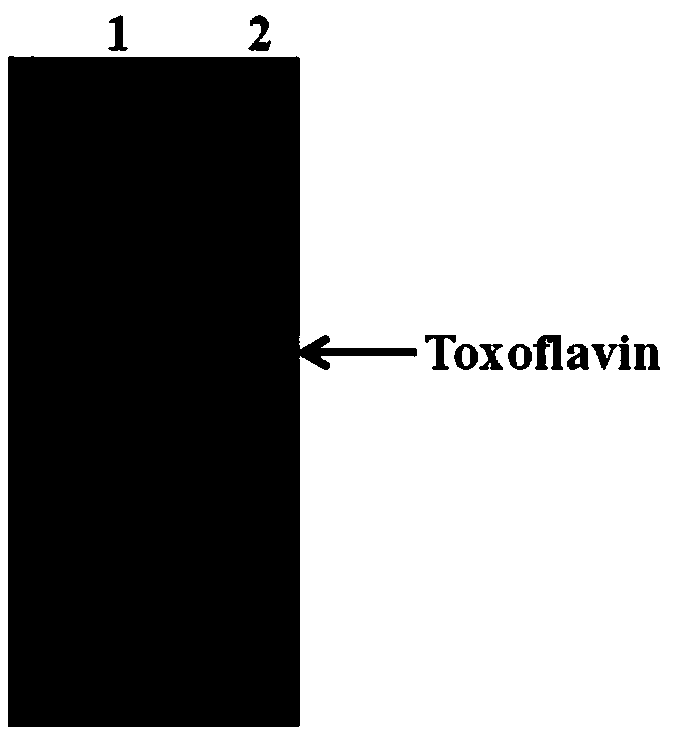

[0046] Thin-layer chromatography: respectively dissolve the fermentation broth extract and standard toxin of the bacterial strain in the methanol of the same volume, spot on one end of the thin-layer silica gel G plate, develop solvent (chloroform: methanol: water) (70:25 :5, V / V) (see figure 1 ).

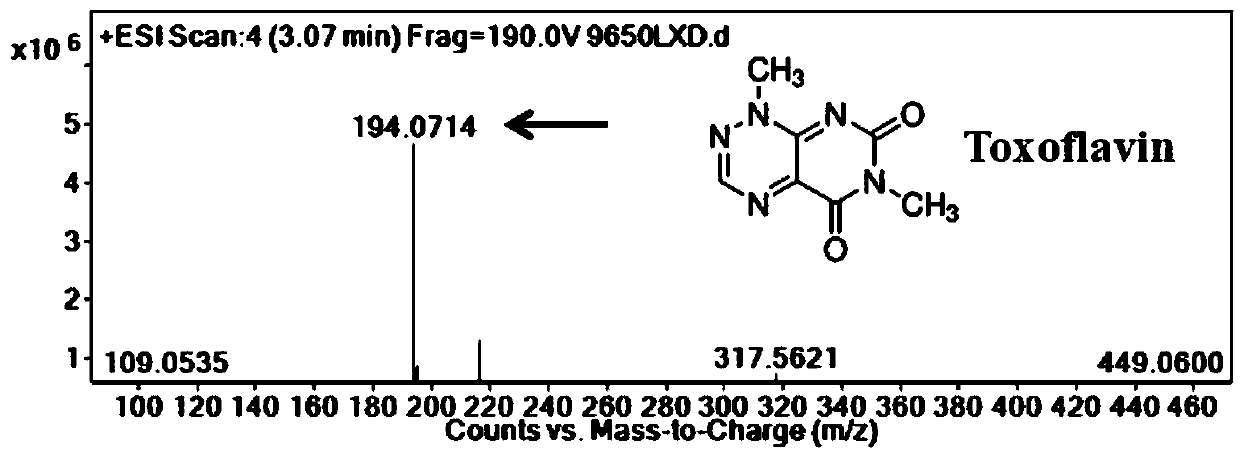

[0047] Mass spectrometry detection: Burkholderia sp.HDXY-02 liquid fermentation toxoflavin fermentation liquid extract has the same ion peak of m / z=194.0714 as the standard product toxoflavin. The result shows that the fermentation liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com