A kind of plastic enhanced tensile strength 590mpa grade cold-rolled dual-phase steel and production method thereof

A tensile strength, dual-phase steel technology, applied in the field of metallurgical sheet production, to achieve the effect of improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

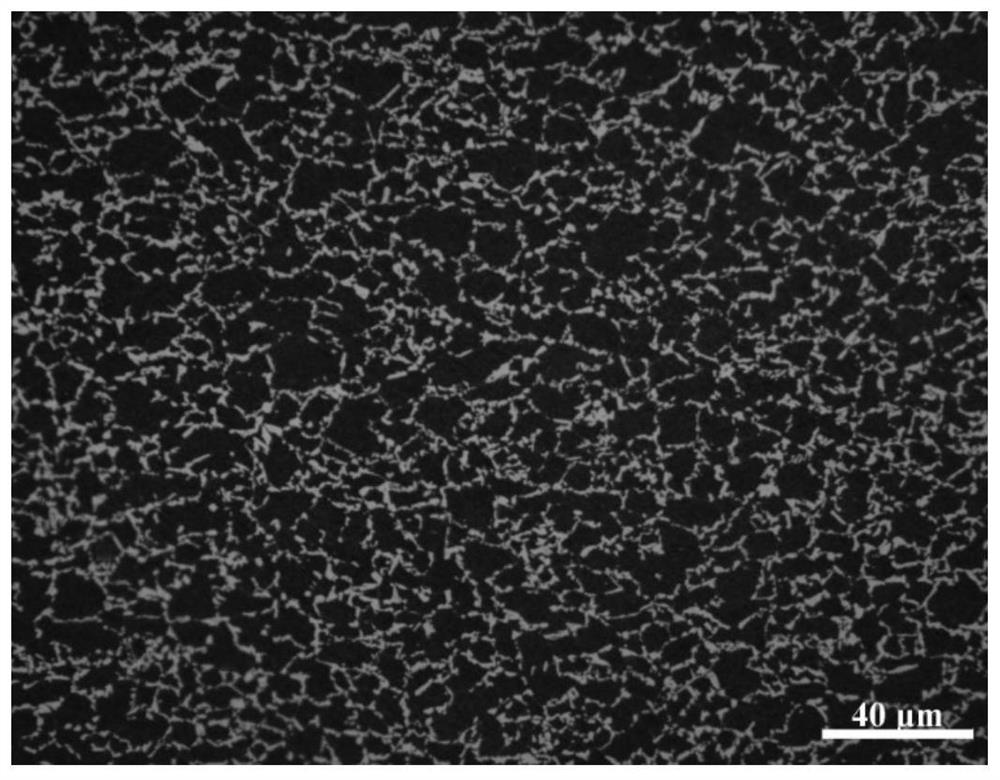

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with examples.

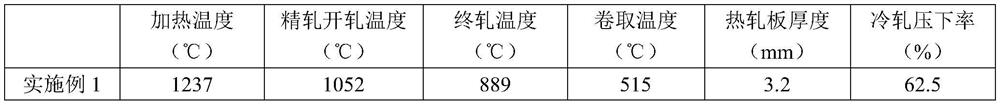

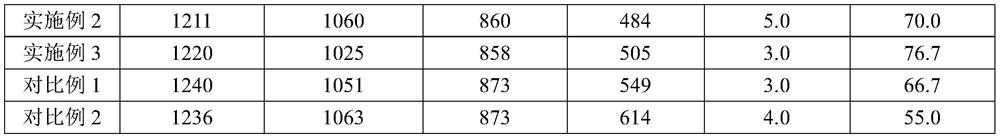

[0033] The cold-rolled dual-phase steel production steps and process parameter control ranges in each embodiment are as follows:

[0034] 1) According to the process route of molten iron pretreatment→converter smelting→alloy fine-tuning→LF furnace refining→continuous casting, it is smelted and poured into billets;

[0035]2) The slab is heated to 1200-1240°C, after dephosphorization and 6 passes of rough rolling, and 7 passes of finish rolling, the start temperature of finish rolling is 1000-1080°C, the outlet temperature is 840-890°C, the Flow cooling to 480 ~ 530 ℃, then coiled and air cooled;

[0036] 3) Cold rolling after conventional pickling, the cold rolling reduction rate is 55-80%;

[0037] 4) Carry out continuous annealing, the steel coil is heated to 780-820°C, and after heat preservation, it is slowly cooled to 650-700°C at a cooling rate of 6-16°C / s, and then cooled at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com