Special-shaped precast pile zipper type supporting structure and construction method thereof

A technology of support structure and construction method, which is applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., can solve problems such as failure to form continuity, water leakage, endangering the safety of foundation pits, etc., to reduce the scope of land use, save concrete, The effect of increasing the rigidity of the pile body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

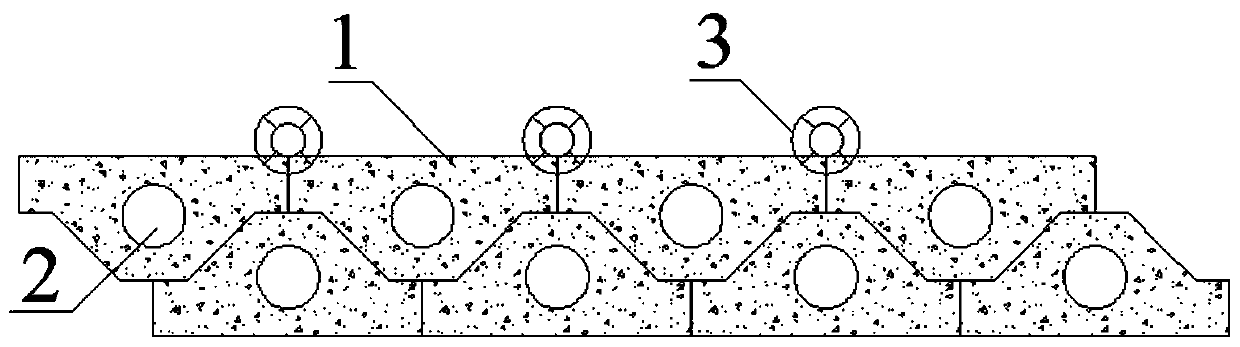

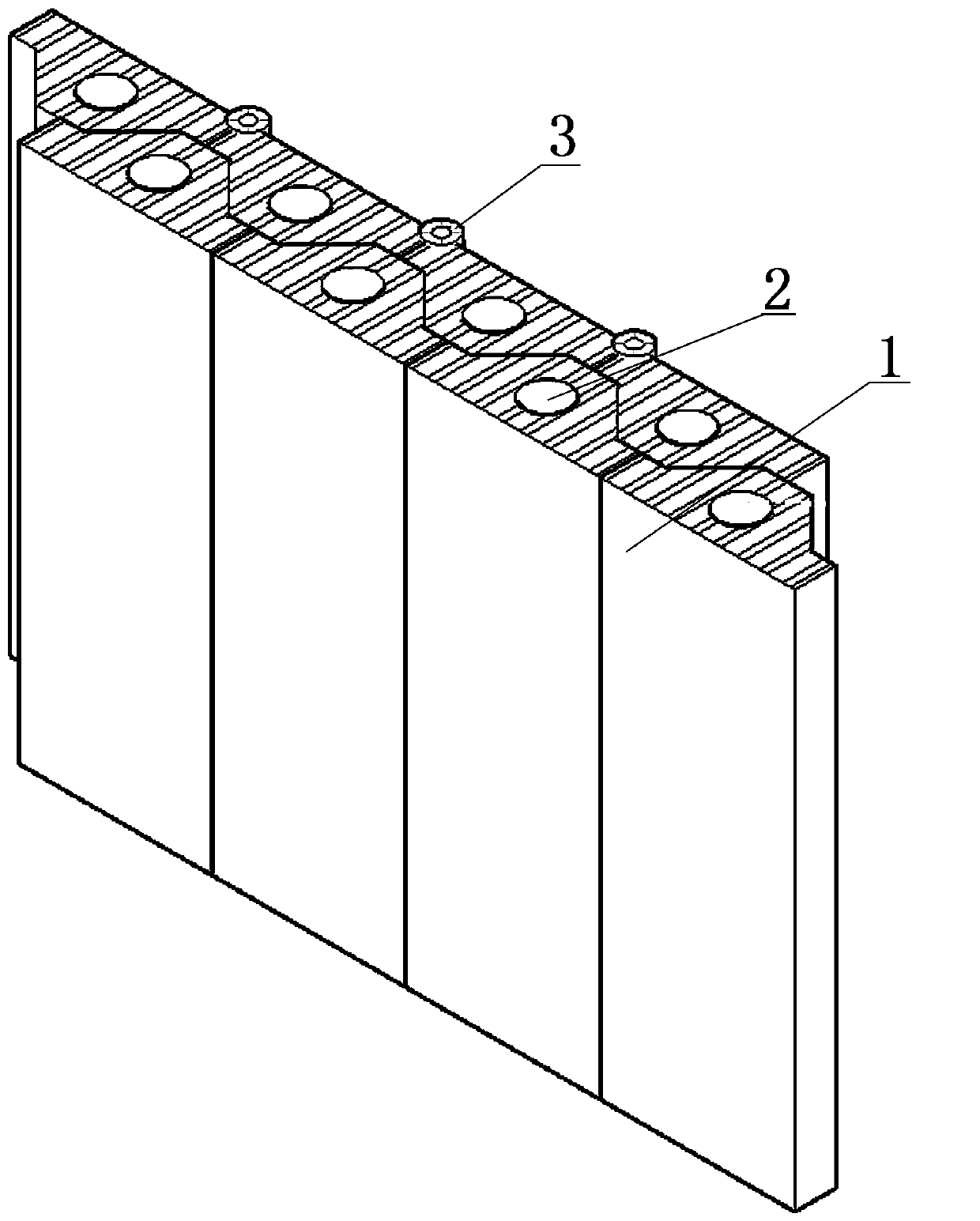

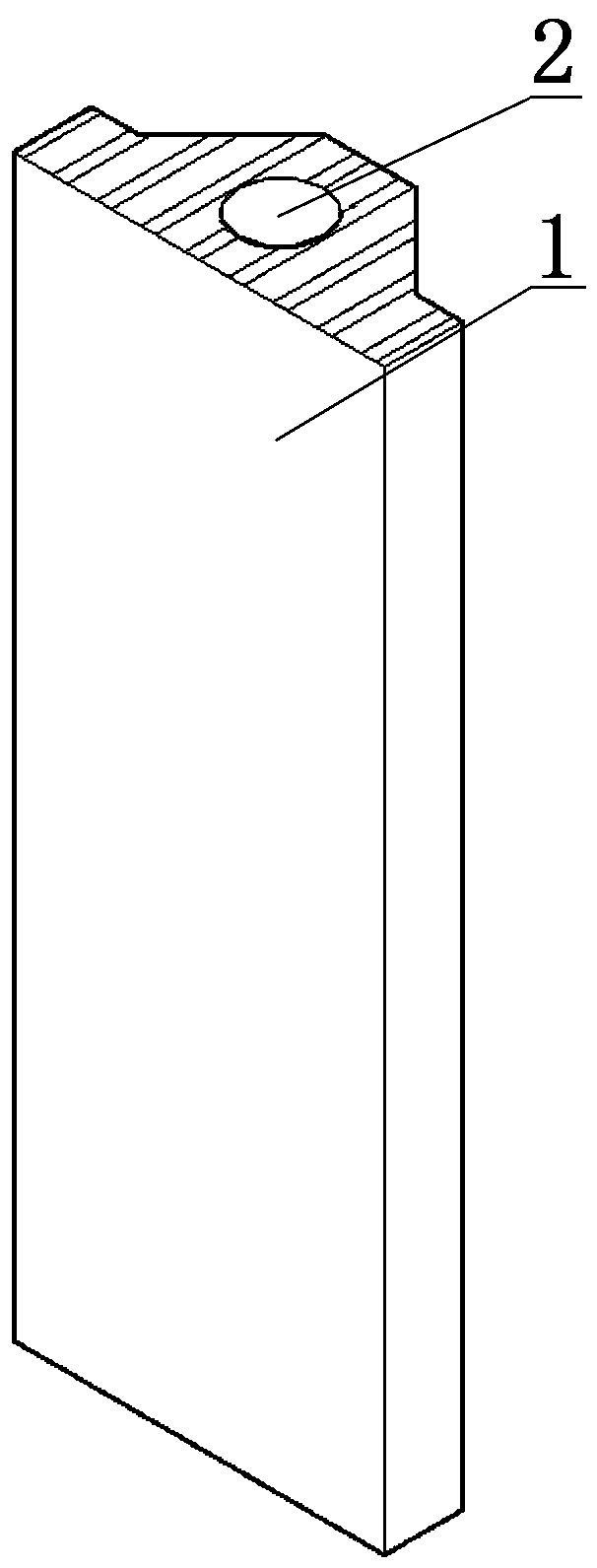

[0050] like Figure 1~5 As shown, the special-shaped prefabricated pile zipper support structure of the present invention is mainly composed of special-shaped prefabricated support piles 1 juxtaposed and dislocated and symmetrically constructed; supporting structure. At the joints formed by the two parallel-constructed special-shaped prefabricated piles, the high-pressure jet spraying mixing piles 3 are constructed to seal the gaps, and then the concrete crown beams 5 are set to form the entire supporting system.

[0051] In this implementation case, the special-shaped prefabricated pile 1 is a concrete prefabricated pile, the concrete strength grade of the pile body is C60-C80, the length of the long side is 1200mm, the length of the short side is 300mm, and the height of the short T is 550mm. The pile body of the special-shaped prefabricated pile is hollow, wherein the hollow is a hollow circle 2 with a diameter of 300mm; the steel rod 5 for prestressed concrete set in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com