Saturated silty-fine sand layer induced grouting experimental model and experimental method

An experimental model and experimental method technology, applied in the field of foundation grouting reinforcement treatment, can solve the problems of no grout penetration, poor grouting effect, poor permeability and injectability of saturated powder fine layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

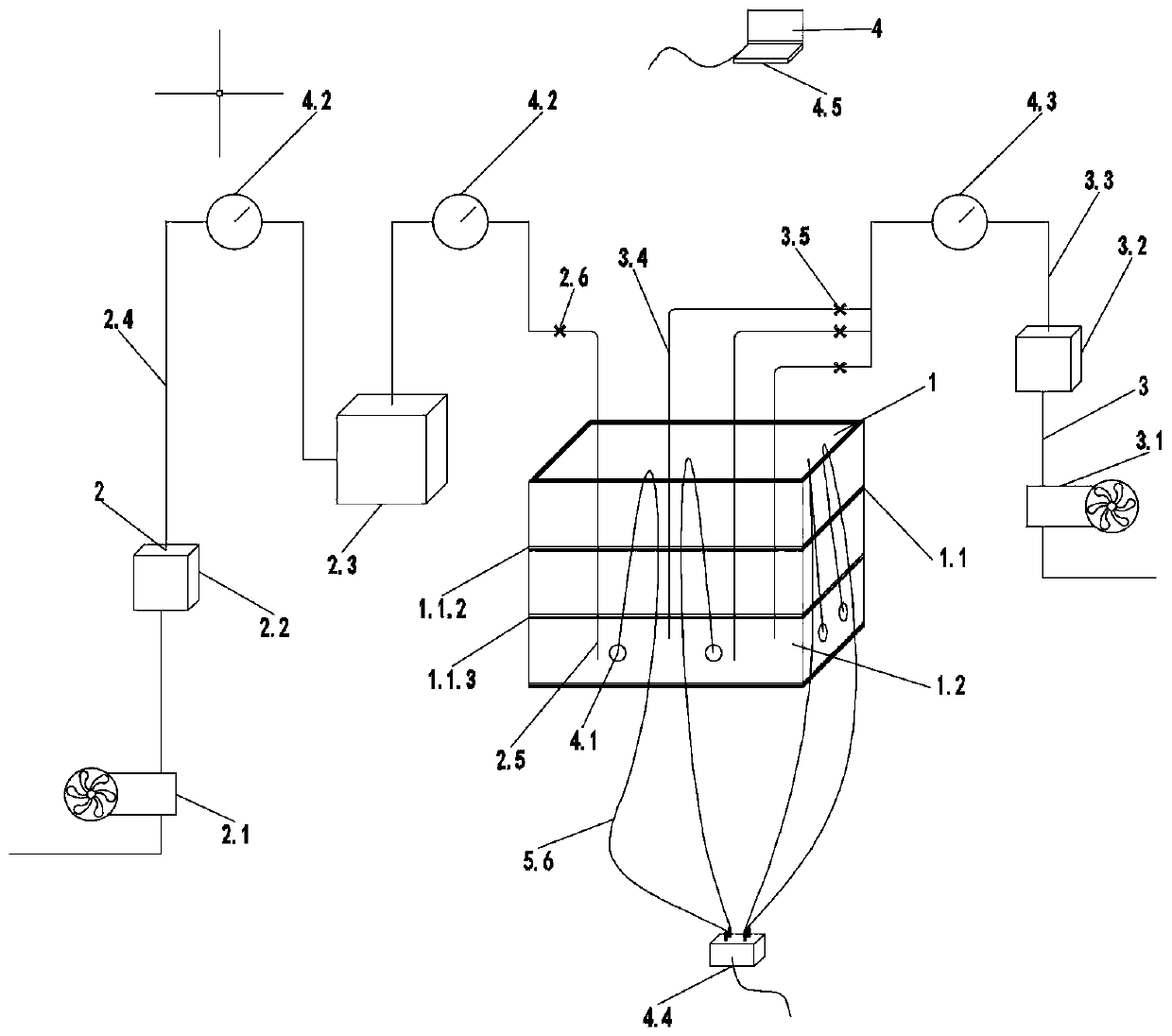

[0076] (1) Equipment selection and model installation

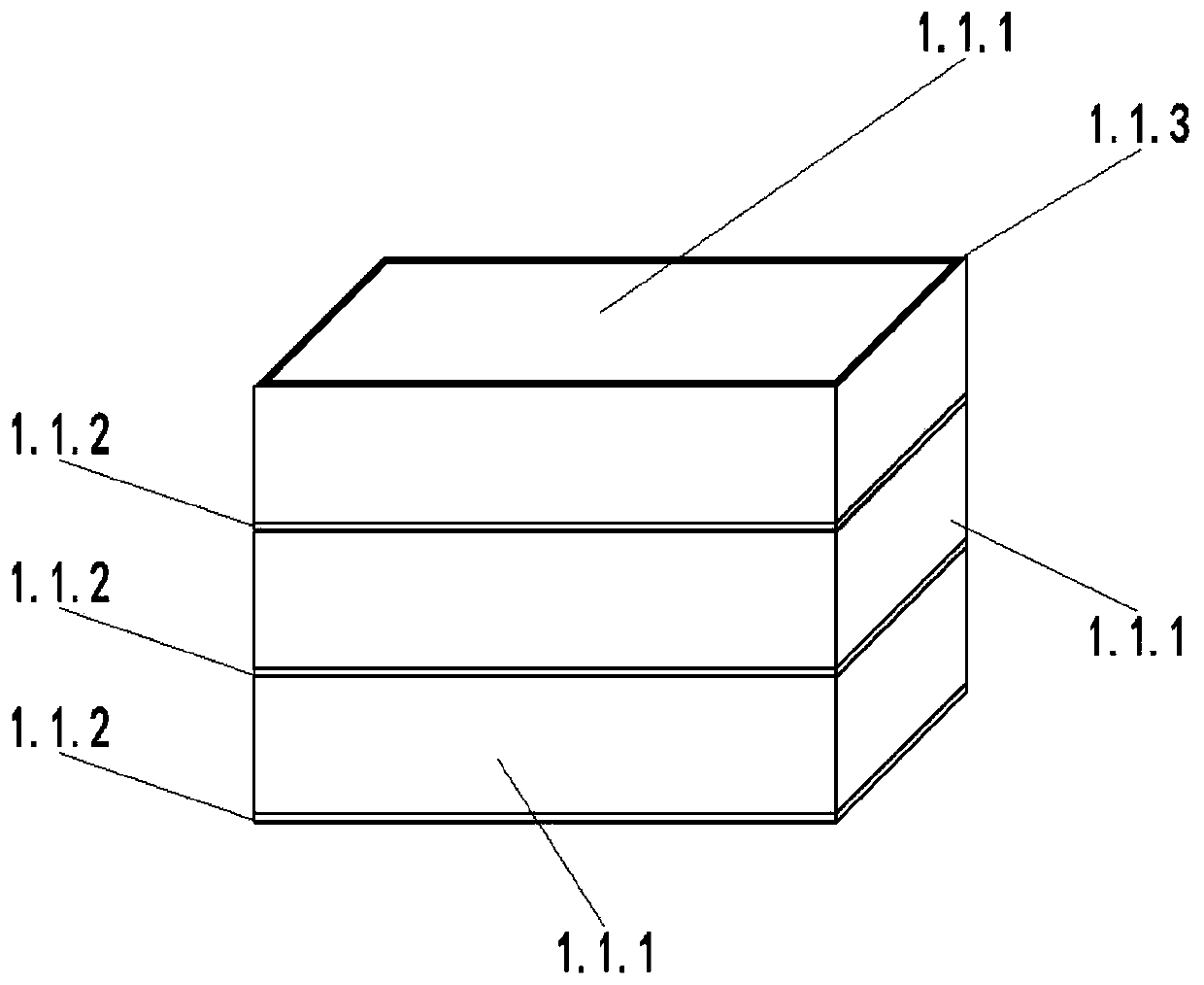

[0077] The production of the model tank (1.1): the model tank (1.1) adopts a cuboid with a length of H, a width of B, and a height of H, and a model tank plate (1.1.1) made of organic glass with a thickness of h is used to splice the tank body. It is convenient to observe the grouting situation in the soil body and the diffusion situation of the grout (5.1). The connection between the side plate and the top cover plate is sealed with a rubber gasket (1.1.3) and reinforced with a steel reinforcement strip (1.1.2) with high rigidity to prevent the tank body from being deformed due to excessive internal pressure Even destroy.

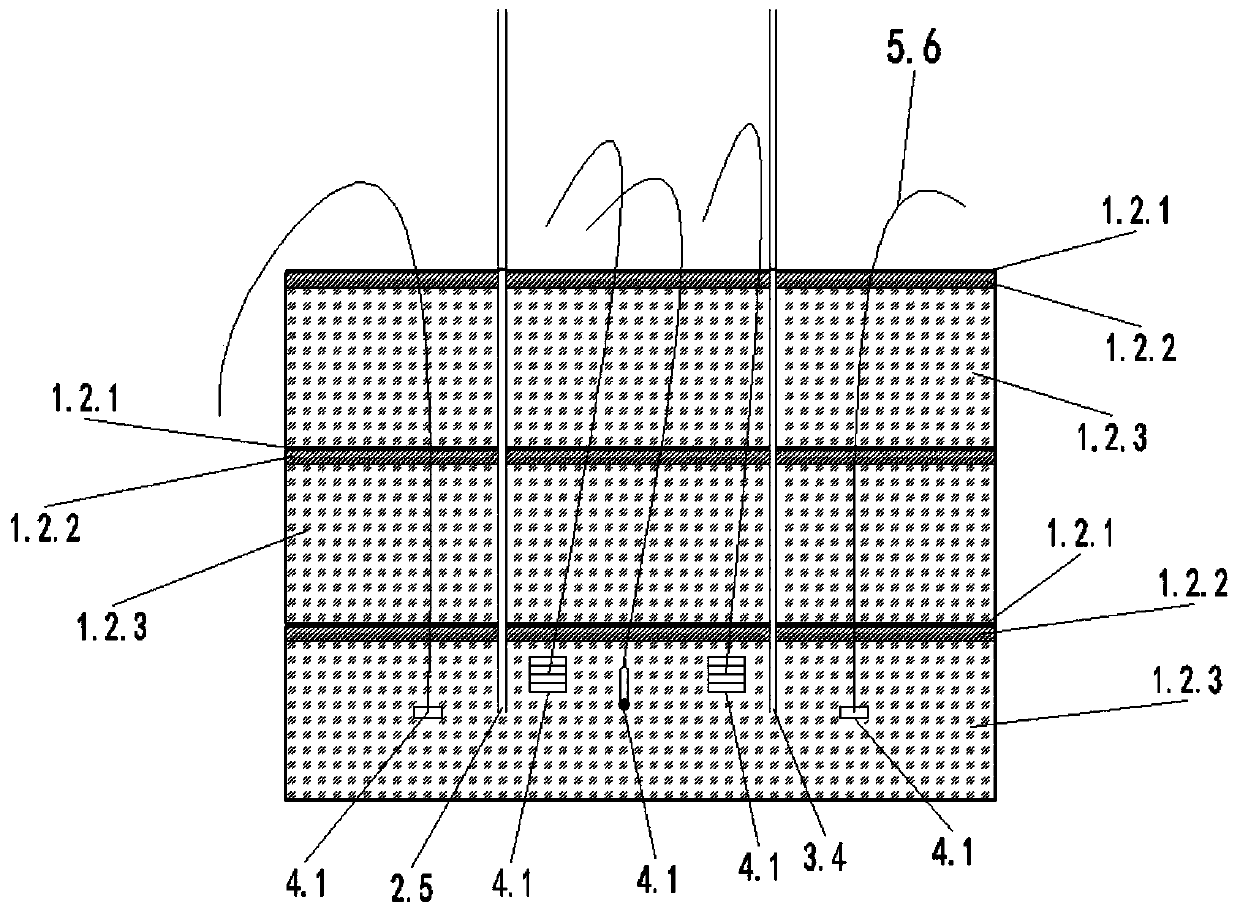

[0078] Soil (1.2) production and filling: the experimental soil is replaced by machine-made quartz sand and river sand, and the thickness of each layer of fine sand layer (1.2.3) is h according to the size of the model tank (1.1). 1 , the thickness of the aquifer is h 2 Clay waterstop (1.2.2) and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com