LNG skid-mounted station control system and installation method

A technology of station control system and control unit, applied in general control system, control/adjustment system, program control, etc., can solve the problems of difficult selection of instrument equipment, high construction cost, and difficulty in alignment, and achieve more convenience. The effect of project utilization, simplifying on-site construction and reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

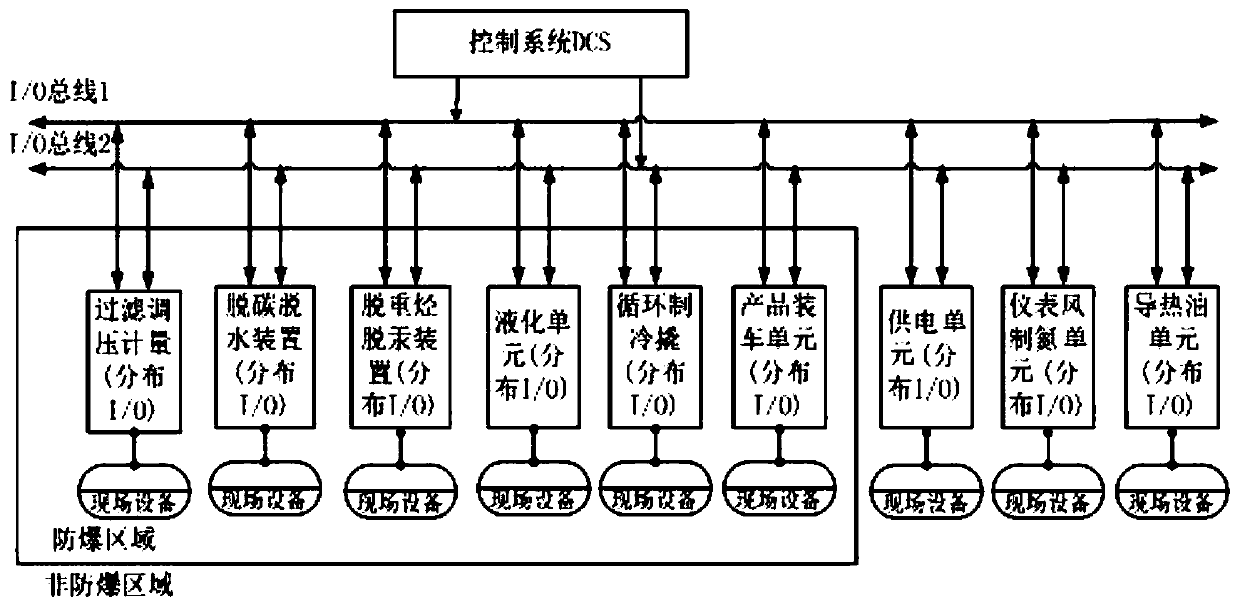

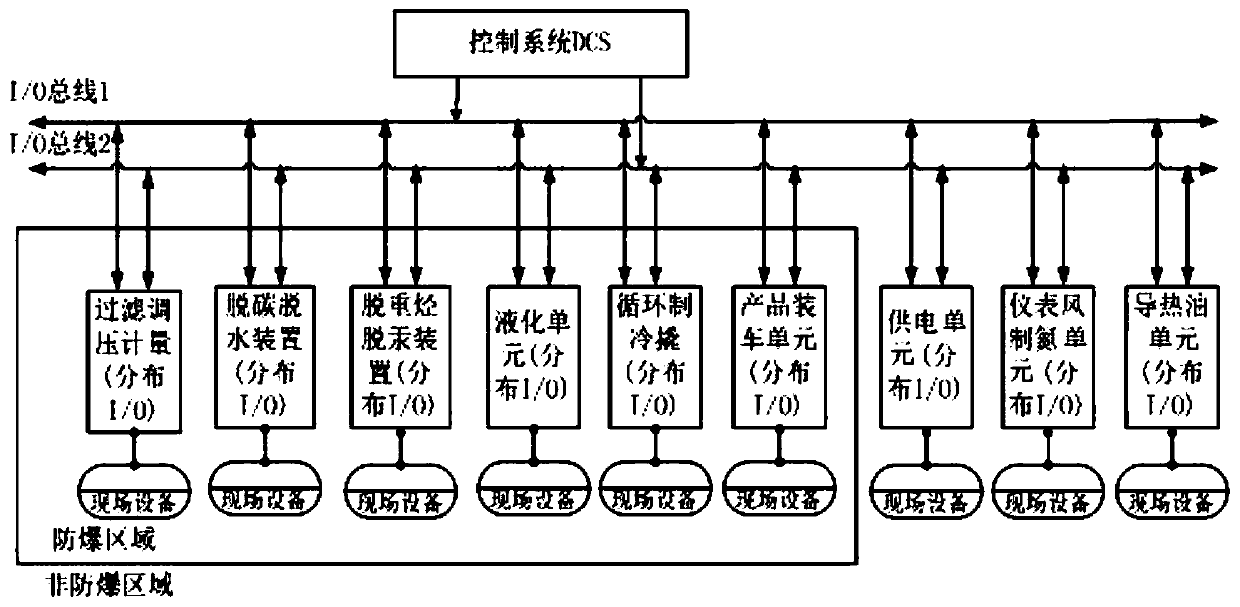

[0018] like figure 1 As shown, a station control system for an LNG skid loading station includes a plurality of skids installed in the LNG skid loading station. Refrigeration skid, product loading unit, power supply unit, instrument air nitrogen unit and heat transfer oil unit. Filtration and pressure regulating metering, decarbonization and dehydration device, heavy hydrocarbon and mercury removal device, liquefaction unit, circulating refrigeration skid, product loading unit, power supply unit, instrument air nitrogen unit and heat transfer oil unit are respectively connected with instruments and valves, and each Each skid is equipped with an independent I / O module. The I / O module includes a redundant communication interface and an I / O card. The instrument valve is connected to the skid point-to-point through the I / O card. The rest of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com