Photo-thermal catalytic CO2 hydrogenation reaction catalyst and preparation method thereof

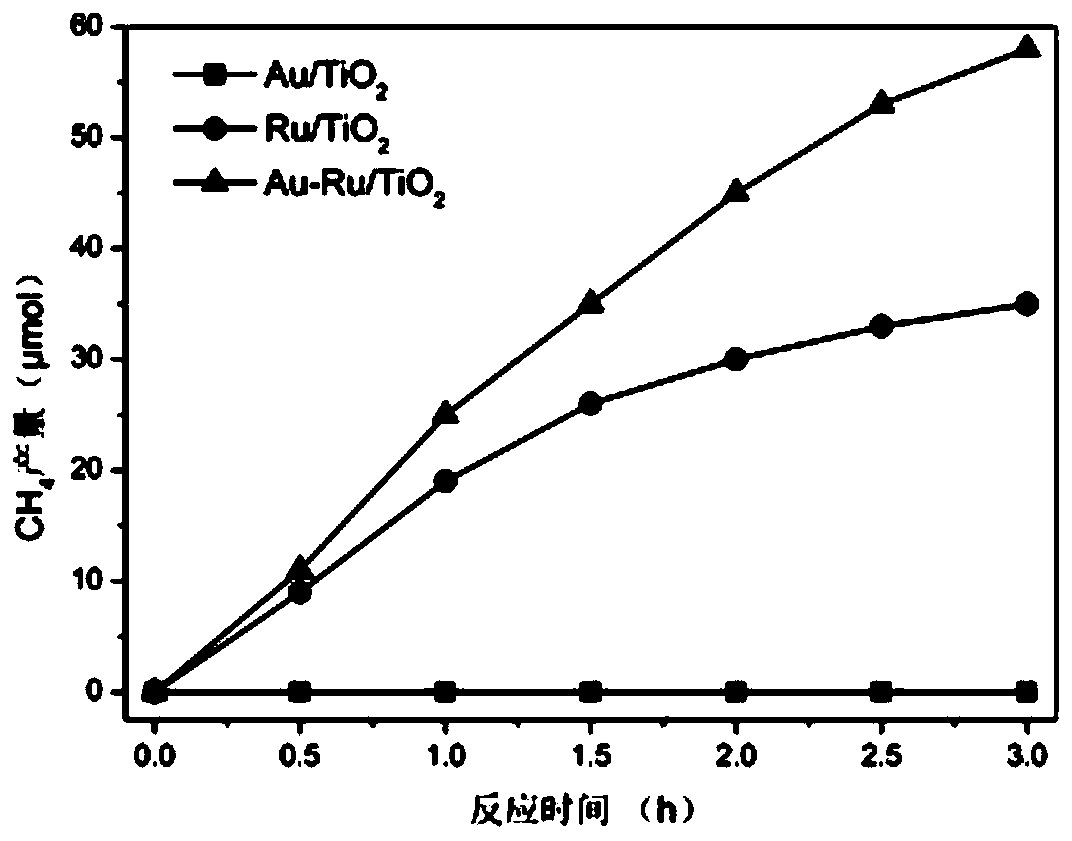

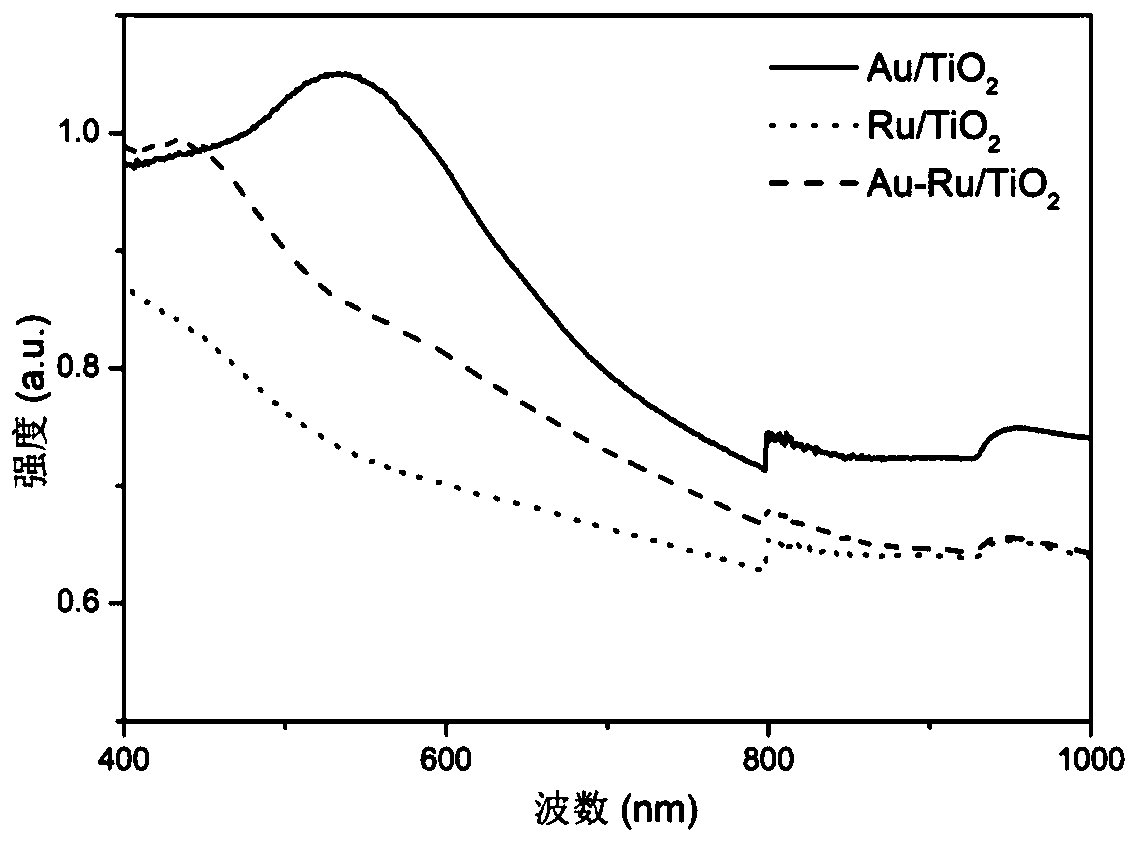

A technology of hydrogenation reaction and photothermal catalysis, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, carbon compound catalyst, etc., can solve the problem of low hydrogenation reaction efficiency and achieve considerable output , improve efficiency, enhance the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The above-mentioned photothermocatalytic CO 2 The preparation method of hydrogenation reaction catalyst, it comprises the following steps carried out in sequence:

[0038] S1 produces precipitation: the TiO 2 After being dispersed in the first deionized water, add chloroauric acid solution and ruthenium chloride solution to react to produce precipitate;

[0039] S2 reduction reaction: add NaOH solution to adjust the pH to 10, then add NaBH 4 solution, undergoing a reduction reaction to generate the catalyst.

[0040] Further, in step S1, TiO 2 It is mixed with the first deionized water in a weight-to-volume ratio of 1 g: 50-150 ml.

[0041] Further, in step S1, the concentration of the chloroauric acid solution is 0.03-0.07M, and the added amount of the chloroauric acid solution is 1-3% of the volume of the first deionized water.

[0042] Further, in step S1, the concentration of the ruthenium chloride solution is 0.2-0.4M, and the added amount of the ruthenium chlor...

Embodiment 1

[0052] A photothermocatalytic CO 2 The preparation method of hydrogenation reaction catalyst, it comprises the following steps:

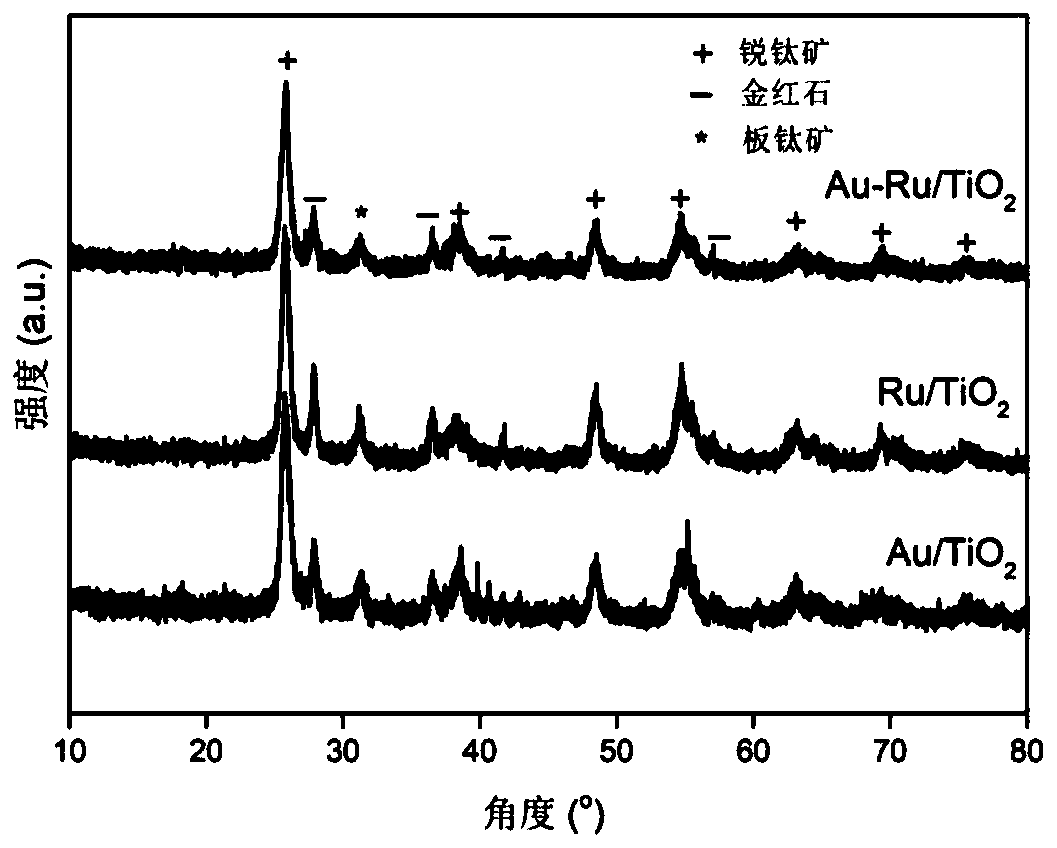

[0053] S1TiO 2 Preparation: after dissolving tetrabutyl titanate in ethanol, stirring for 20 min, it was added dropwise to the second deionized water, the volume ratio of tetrabutyl titanate, ethanol solution and the second deionized water was 15: 50:100 stirring to evaporate to obtain a white powder, calcined at 400°C for 3h to obtain TiO 2 .

[0054] S2: Au-Ru / TiO 2 Preparation: 1gTiO 2 After being dispersed in 150 ml of the first deionized water, add a chloroauric acid solution having a concentration of 0.04M at a concentration of 1% of the volume of the first deionized water and a solution of 0.2 M at a concentration of 3% of the volume of the first deionized water. M ruthenium chloride solution; after adding 0.1M NaOH solution to adjust the pH to 10, after stirring for 22min, add 0.6M NaBH at a concentration of 2% of the volume of the firs...

Embodiment 2

[0056] Photothermocatalytic CO 2 The preparation method of hydrogenation reaction catalyst comprises the following steps:

[0057] TiO 2 It was prepared by the following method: Dissolve 15ml of tetrabutyl titanate in 50ml of ethanol solution, add it dropwise into the deionized aqueous solution after stirring for 30 minutes, continue to stir for 3 hours, and evaporate the solution to obtain a white powder. The powder is calcined at 400°C for 1 to 3 hours to obtain TiO 2 .

[0058] Au-Ru / TiO 2 Preparation: 1gTiO 2 Disperse in 100ml of ionized water, add 1ml of chloroauric acid solution (0.05M) and 1ml of ruthenium chloride solution (0.3M), and add 0.1M NaOH solution to adjust the pH to 10, stir for 20min and then add 10ml of NaBH 4 (0.7M) solution, continue to stir for 3h for reduction reaction to generate TiO loaded with Ru and Au alloy 2 , namely Au-Ru / TiO 2 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com