A method of smelting metal materials

A technology of metal materials and smelting methods, applied in the direction of charge, furnace, lighting and heating equipment, etc., can solve the problems of long transportation cycle, difficult storage, long production cycle, etc., to improve the purity of smelting, improve the purity, reduce the smelting cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a method for smelting metal materials, which includes the following steps:

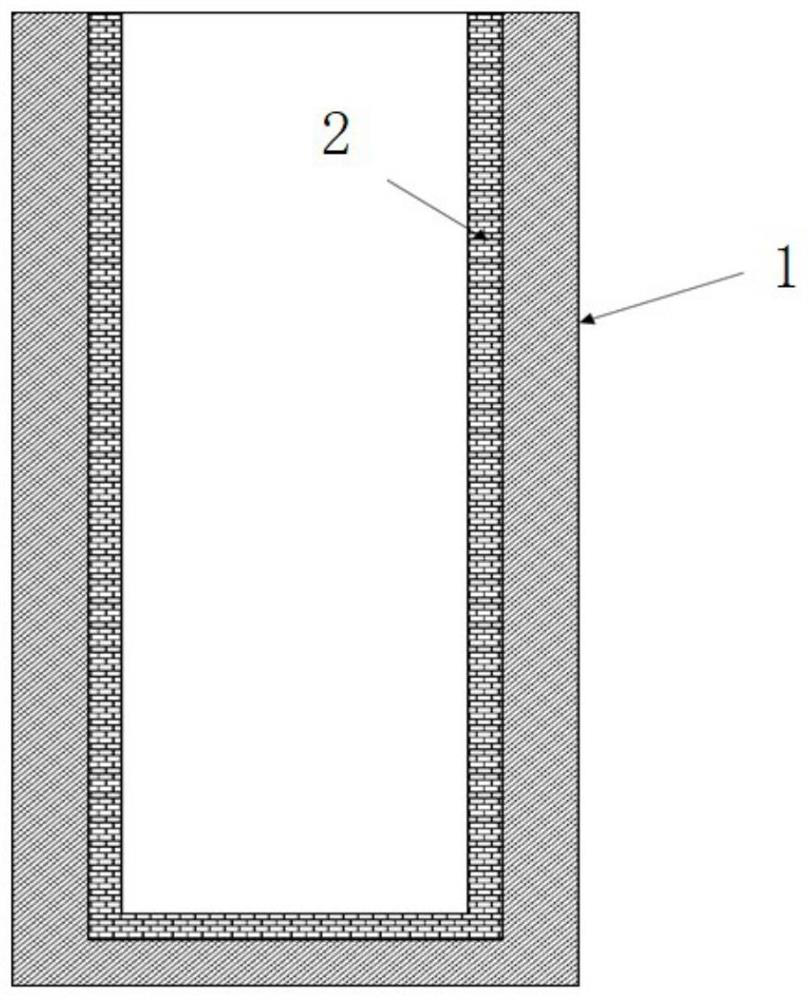

[0045] Step 1) Make a detachable inner layer of the crucible: as in figure 1 As shown, multiple crucible inner layer modules are installed on the inner wall of the crucible body 1, and the multiple crucible inner layer modules form a detachable crucible inner layer 2 to obtain a double-layer crucible; wherein, the crucible inner layer modules are made of metal It is made of materials with purification effect;

[0046] Step 2) Step of smelting the metal material: placing the metal material in the double-layer crucible for smelting.

[0047] Here, the crucible body 1 in this embodiment may be a commercial crucible, such as a magnesia crucible, an alumina crucible, a calcium oxide crucible, a zirconia crucible, and the like.

[0048] Here, in the metal material smelting method provided in this embodiment, when the metal material is smelted, a detachable crucible inner la...

Embodiment 2

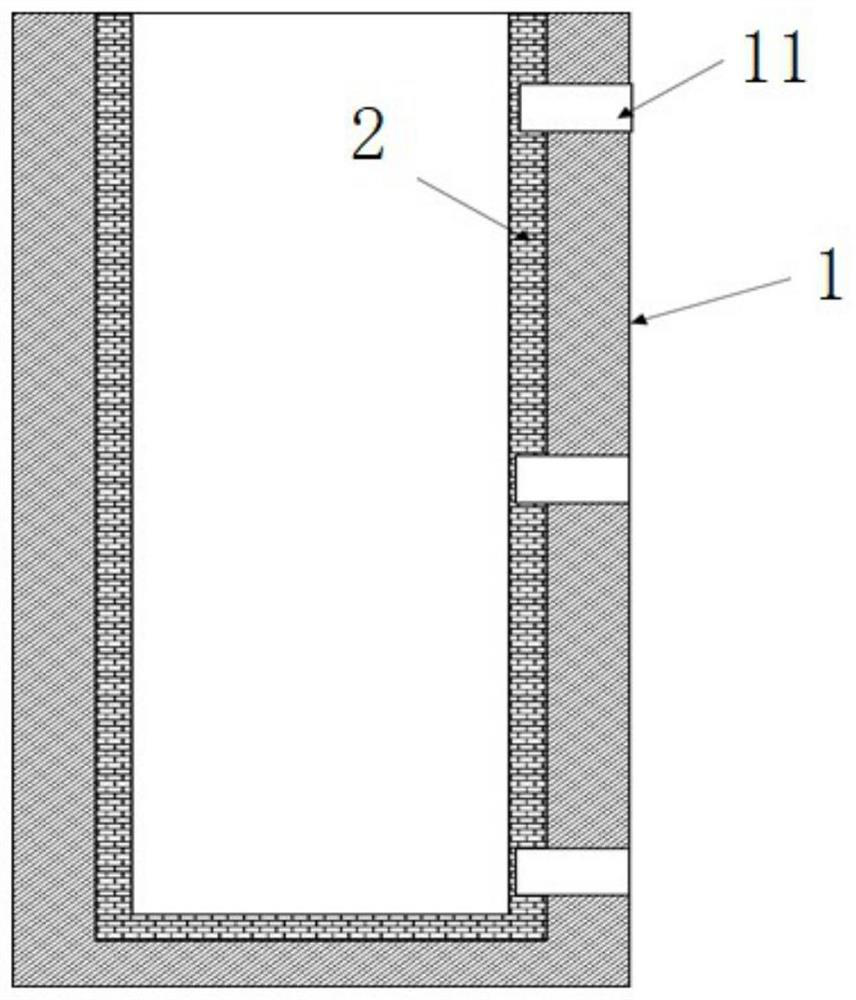

[0051] Preferably, this embodiment provides a method for smelting metal materials. Compared with the previous embodiment, in order to further improve the purity of the smelted metal of metal materials, in this embodiment, in the step of making a detachable inner layer of the crucible :

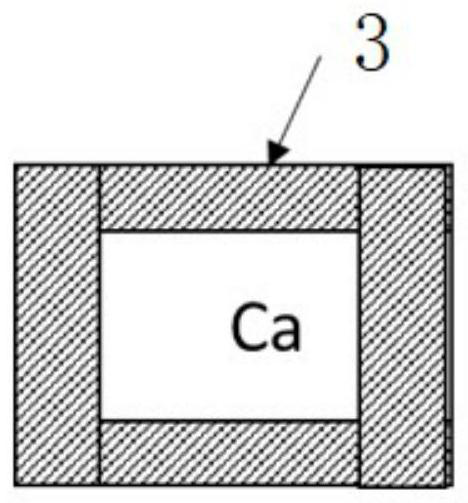

[0052] Such as image 3 and Figure 4 As shown, the inner layer of the crucible is provided with a holding tank, and a calcium-containing impurity-removing purifier 3 is placed in the accommodating tank; wherein, the calcium-containing impurity-removing purifying agent is located on or near the inner bottom of the crucible body 1 The inner bottom of the crucible body, so that in the later stage of metal smelting, the calcium element penetrates into the molten metal through the gap between the inner modules of the crucible to purify the molten metal.

[0053] Preferably, the calcium-containing impurity removal agent includes an inner layer and an outer layer, and the outer layer wraps the inn...

Embodiment 3

[0056] Preferably, this embodiment provides a method for smelting metal materials. Compared with the above embodiments, the steps of making a detachable inner layer of the crucible in this embodiment include:

[0057] 11) A plurality of crucible inner layer modules are placed in the crucible body, and bonded to the inner wall of the crucible body, and the crucible inner layer is formed by stacking to obtain a double-layer crucible.

[0058] In this step, the volume of the inner module of the crucible does not exceed 100 cm 3 . Since the bottom of the crucible body is mostly arc-shaped, and the size of the inner composite module of the crucible is too large, it is difficult to splice into an arc-shape. Here, by making the size of the inner module of the crucible not exceed 100cm 3 , to ensure that the inner layer of the spliced crucible is consistent with the curvature of the inner wall of the crucible body.

[0059] Preferably, the surface roughness Ra of the inner module...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com