Activated carbon sewage treatment device and method

A technology of sewage treatment device and sewage treatment tank, applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage treatment equipment, etc. There are many impurities, which affect the recovery of emulsified wastewater and the recovery rate of reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

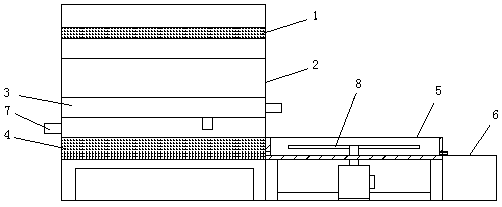

[0028] An activated carbon sewage treatment device includes a first grille filter 1, a sludge dehydrator 2 is arranged at the lower part of the first grille filter 1, and an oil-water separator 3 is fixedly arranged at the lower part of the sludge dehydrator to separate oil and water. The lower part of the device 3 is provided with a second grid filter 4, the second grid filter 4 is connected to the sewage treatment tank 5 through a pipe, and the sewage treatment tank 5 is connected to the heating boiler 6 through a pipe. Activated carbon is uniformly placed on the grid filter 1, an anionic surfactant feeding port 7 is provided on the side of the second grid filter 4, and the sewage treatment tank 5 is provided with a stirring mechanism 8.

[0029] A treatment method of an activated carbon sewage treatment device includes the following steps:

[0030] S1: The waste emulsified wastewater is introduced into the first grid filter 1 for filtration, solid impurities are separated, and t...

Embodiment 2

[0047] An activated carbon sewage treatment device includes a first grille filter 1, a sludge dehydrator 2 is provided at the lower part of the first grille filter 1, and an oil-water separator 3 is fixedly provided at the lower part of the sludge dehydrator for oil-water separation The lower part of the device 3 is provided with a second grid filter 4, the second grid filter 4 communicates with the sewage treatment tank 5 through a pipe, and the sewage treatment tank 5 communicates with the heating boiler 6 through a pipe. Activated carbon is uniformly placed on the grid filter 1, an anionic surfactant feeding port 7 is provided on the side of the second grid filter 4, and the sewage treatment tank 5 is provided with a stirring mechanism 8.

[0048] A treatment method of an activated carbon sewage treatment device includes the following steps:

[0049] S1: The waste emulsified wastewater is introduced into the first grid filter 1 for filtration, solid impurities are separated, and...

Embodiment 3

[0066] An activated carbon sewage treatment device includes a first grille filter 1, a sludge dehydrator 2 is provided at the lower part of the first grille filter 1, and an oil-water separator 3 is fixedly provided at the lower part of the sludge dehydrator for oil-water separation The lower part of the device 3 is provided with a second grid filter 4, the second grid filter 4 communicates with the sewage treatment tank 5 through a pipe, and the sewage treatment tank 5 communicates with the heating boiler 6 through a pipe. Activated carbon is uniformly placed on the grid filter 1, an anionic surfactant feeding port 7 is provided on the side of the second grid filter 4, and the sewage treatment tank 5 is provided with a stirring mechanism 8.

[0067] A treatment method of an activated carbon sewage treatment device includes the following steps:

[0068] S1: The waste emulsified wastewater is introduced into the first grid filter 1 for filtration, solid impurities are separated, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com