Manufacturing method for target material

A production method and target technology, which are applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem that the size cannot be well controlled, and achieve the effect of fine and uniform internal grains and enhanced toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

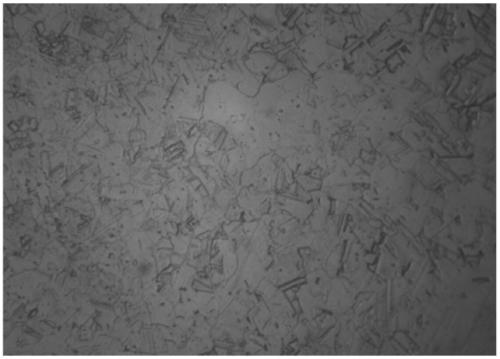

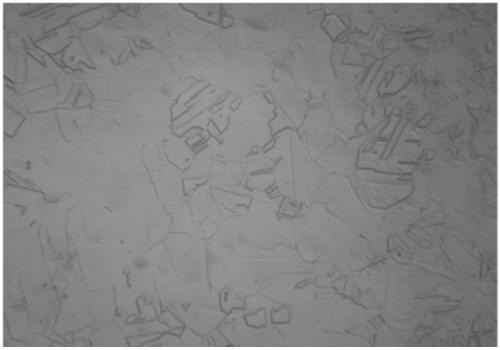

[0024] It can be seen from the background art that in the prior art, in the process of preparing a copper-aluminum alloy sputtering target with an atomic percentage of copper element of 0.25%, it is difficult to control the grain size of the target during the production process.

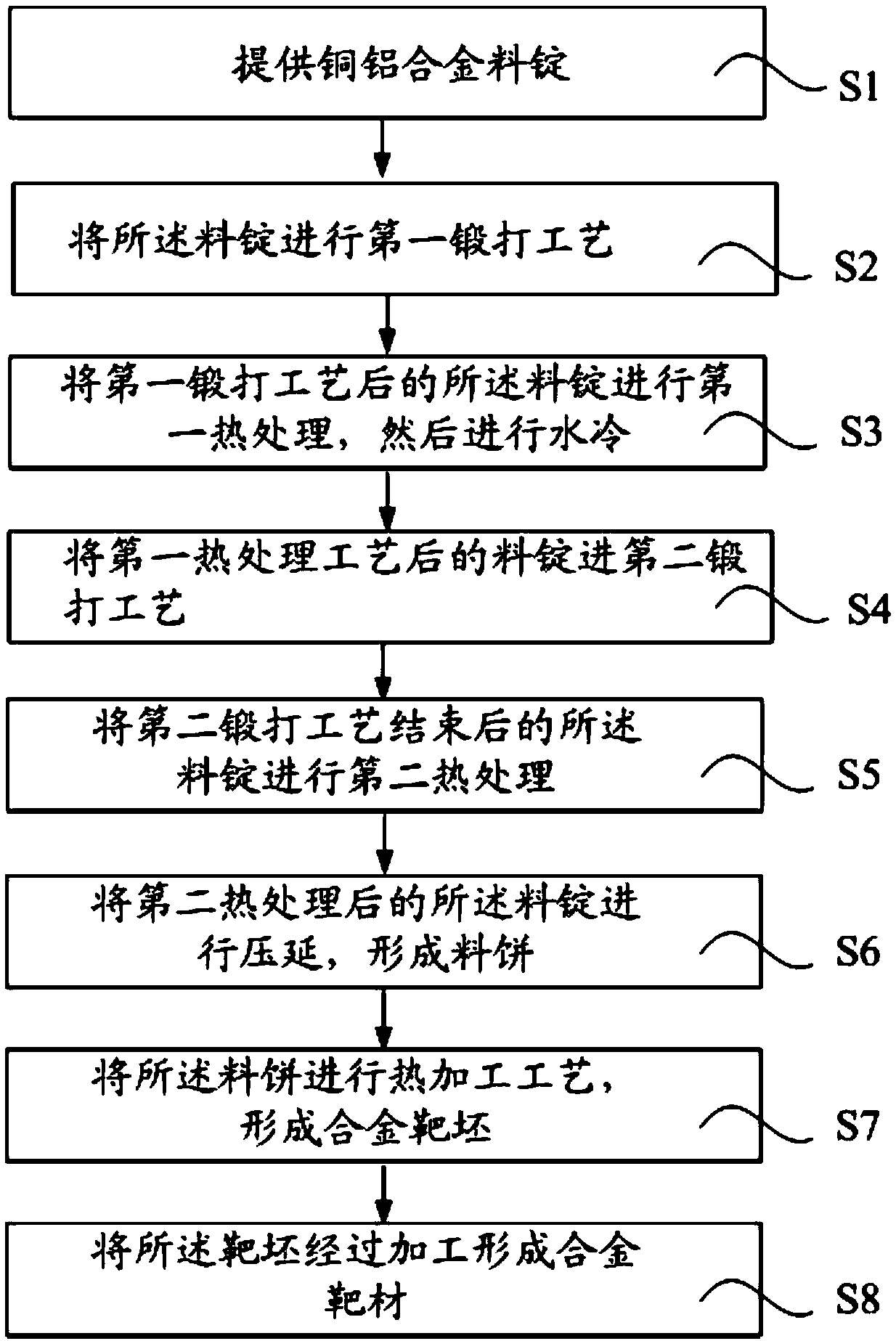

[0025] In order to solve the above problems, the inventor provided a method for preparing the copper-aluminum alloy through creative work, wherein, by providing a calculated copper-aluminum alloy ingot with sufficient weight, the ingot is subjected to a sufficient number of forging processes , so that the original grain structure in the ingot is destroyed to form grains with a new structure, and at the same time, the ingot’s willfulness reaches a certain level, and then the ingot is rolled in all directions by a rolling process, and it will become After the required thickness is met, the thermal processing process is carried out on the ingot. Since the thermal processing process is a metal heat treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com