Aluminum-scandium alloy target material and preparation method thereof

An alloy target, aluminum scandium technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problems of small scandium content selection range, uneven target composition, inability to sputter coating, etc. To achieve the effect of large optional range, uniform composition and structure, and improved film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] An embodiment of the present invention provides a method for preparing an aluminum-scandium alloy target. The method includes: selecting metal aluminum and metal scandium with a purity of more than 99.99% (no particle size requirement); the mass percentage of metal scandium is 5%~ 40%, and the mass percentage content of metal aluminum is 60% to 95%. The metal aluminum is mixed into metal scandium in pairs, and the mass of metal aluminum mixed each time does not exceed 200% of the total mass of scandium. Hold the heat for 5-15 minutes for the first time, and obtain the expected aluminum-scandium alloy through repeated melting; then cast the aluminum-scandium alloy melt into the mold to obtain the aluminum-scandium alloy target blank; press the aluminum-scandium alloy target blank to obtain aluminum-scandium alloy through pressure processing and heat treatment alloy target. Among them, the mold can be selected from water-cooled copper mold, or cast iron mold with air cool...

Embodiment 1

[0028] Select 3600g of metal aluminum with a purity of more than 99.99%, select 400g of metal scandium with a purity of more than 99.99%, and divide the metal aluminum into 7 parts. Put the scandium metal into the water-cooled copper crucible, put the first metal aluminum into the feeder, evacuate the suspension furnace to below 1Pa, and fill it with inert gas; Turn the alloy ingot into a water-cooled copper crucible, then add a second portion of metal aluminum to the feeder, melt and keep it warm again according to the above method, and repeat the above steps until an aluminum-scandium alloy with a scandium content of 10% is obtained; finally, the alloy solution is cast into In a Φ200mm water-cooled copper mold, an aluminum-scandium alloy target blank was obtained.

[0029] After peeling the above aluminum-scandium alloy ingot, heat the ingot and the Φ215mm steel mold at 520°C for 60min. Place the heat-preserved aluminum-scandium alloy ingot and mold under a forging press to...

Embodiment 2

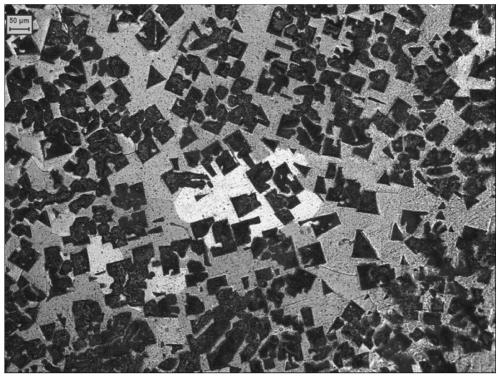

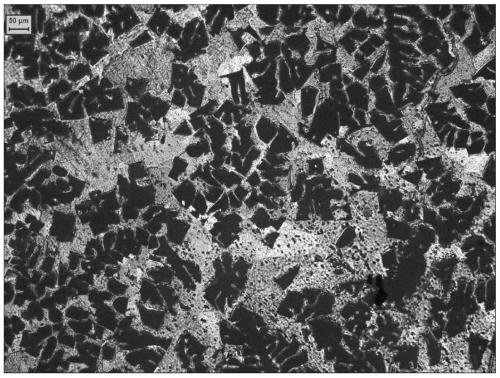

[0032] Select 3200g of metal aluminum with a purity of more than 99.99%, select 800g of metal scandium with a purity of more than 99.99%, and divide the metal aluminum into 3 parts. Metal scandium is put into a water-cooled copper crucible, the first metal aluminum is put into a feeder, the suspension furnace is evacuated to below 1Pa, and inert gas is filled. After metal scandium is melted, add aluminum, smelt and keep warm for 10 minutes, after cooling and taking out, turn the alloy ingot into a water-cooled copper crucible, then add the second metal aluminum to the feeder, and repeat the above method until the scandium content reaches 20% aluminum scandium alloy. Finally, the alloy solution was cast into a Φ200mm water-cooled copper mold to obtain an aluminum-scandium alloy target blank. The internal microstructure photo of the aluminum-scandium alloy target embryo is as follows: figure 1 shown.

[0033] After peeling the aluminum-scandium alloy ingot, the aluminum-scand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com