TPEE acoustic film and production method thereof

An acoustic and film technology, applied in the field of TPEE acoustic film, can solve the problems of affecting the service life of materials, high price of PTFE, poor performance stability, etc., and achieve the effects of convenient operation, improved acoustic performance and low preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

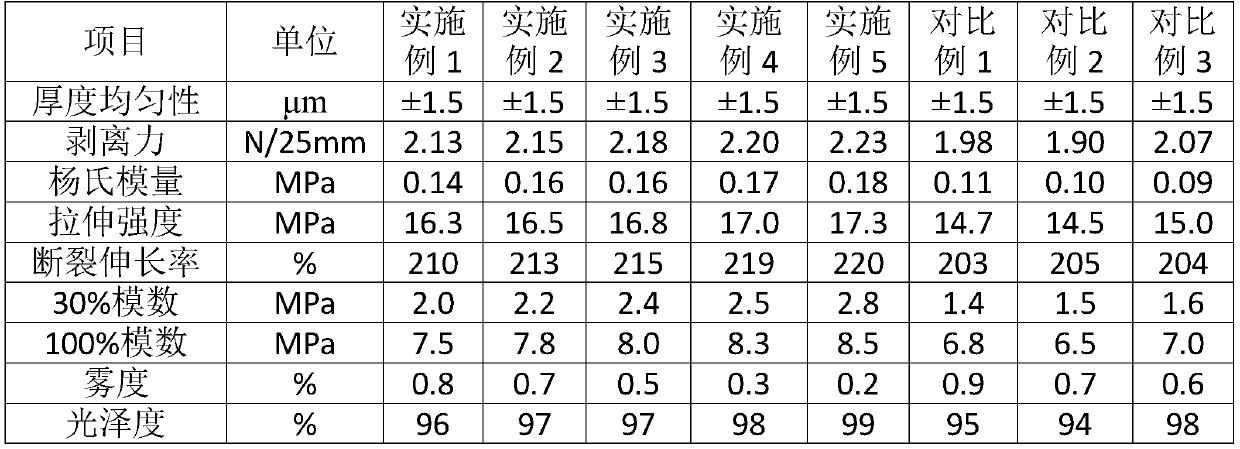

Examples

Embodiment 1

[0033] A TPEE acoustic film is characterized in that it comprises a modified TPEE film and a backing film formed by laminating an adhesive; the modified TPEE film is made of the following raw materials in parts by weight: 60 parts of TPEE, 15 parts of radiation-grafted modified TPEE, 5 parts of fluorine-containing epoxy resin, 2 parts of nano-titanium dioxide, 1 part of silane coupling agent KH550, 0.5 part of methyl silicone oil, and 10100.2 parts of antioxidant.

[0034] For the preparation method of the fluorine-containing epoxy resin, refer to: Wang Chengzhong, Zuo Yu, Synthesis and Performance Research of Fluorine-Containing Epoxy Resin [J]. Thermosetting Resin, 2009 (01): 14-16, specifically comprising the following steps: Add 2,4-diisocyanate into the three-necked flask, add dodecafluoroheptanol dropwise at 60°C, drop it within 1 hour, then raise the temperature to 85°C to react for 2 hours, add epoxy resin DGEBA at 100°C ℃ for 2 hours, then precipitated in water, place...

Embodiment 2

[0040] A TPEE acoustic film is characterized in that it comprises a modified TPEE film and a backing film laminated by an adhesive; the modified TPEE film is made of the following raw materials in parts by weight: 63 parts of TPEE, 17 parts of radiation-grafted modified TPEE, 6 parts of fluorine-containing epoxy resin, 3 parts of nano-titanium dioxide, 1.2 parts of silane coupling agent KH560, 0.7 parts of phenyl silicone oil, and 1680.3 parts of antioxidant.

[0041] For the preparation method of the fluorine-containing epoxy resin, refer to: Wang Chengzhong, Zuo Yu, Synthesis and Performance Research of Fluorine-Containing Epoxy Resin [J]. Thermosetting Resin, 2009 (01): 14-16, specifically comprising the following steps: Add 2,4-diisocyanate into the three-necked flask, add dodecafluoroheptanol dropwise at 60°C, drop it within 1 hour, then raise the temperature to 85°C to react for 2 hours, add epoxy resin DGEBA at 100°C ℃ for 2 hours, then precipitated in water, and placed...

Embodiment 3

[0047] A TPEE acoustic film is characterized in that it comprises a modified TPEE film and a backing film laminated by an adhesive; the modified TPEE film is made of the following raw materials in parts by weight: 65 parts of TPEE, 20 parts of radiation-grafted modified TPEE, 7.5 parts of fluorine-containing epoxy resin, 4 parts of nano-titanium dioxide, 1.5 parts of silane coupling agent KH570, 1 part of methyl ethoxy silicone oil, and 0.4 part of antioxidant 1076.

[0048] For the preparation method of the fluorine-containing epoxy resin, refer to: Wang Chengzhong, Zuo Yu, Synthesis and Performance Research of Fluorine-Containing Epoxy Resin [J]. Thermosetting Resin, 2009 (01): 14-16, specifically comprising the following steps: Add 2,4-diisocyanate into the three-necked flask, add dodecafluoroheptanol dropwise at 60°C, drop it within 1 hour, then raise the temperature to 85°C to react for 2 hours, add epoxy resin DGEBA at 100°C ℃ for 2 hours, then precipitated in water, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com