Porous painted pottery microspheres based on ceramic wastes and preparation method thereof

A technology of ceramic waste and ceramic micropowder, applied in ceramic products, ceramic material production, clay products, etc., can solve problems such as difficulty in accurately controlling pore growth, inability to prepare different types of pore structures, and single color of ceramic microspheres, etc. Achieve the effect of developed porosity, improved pore-making capacity, and good economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

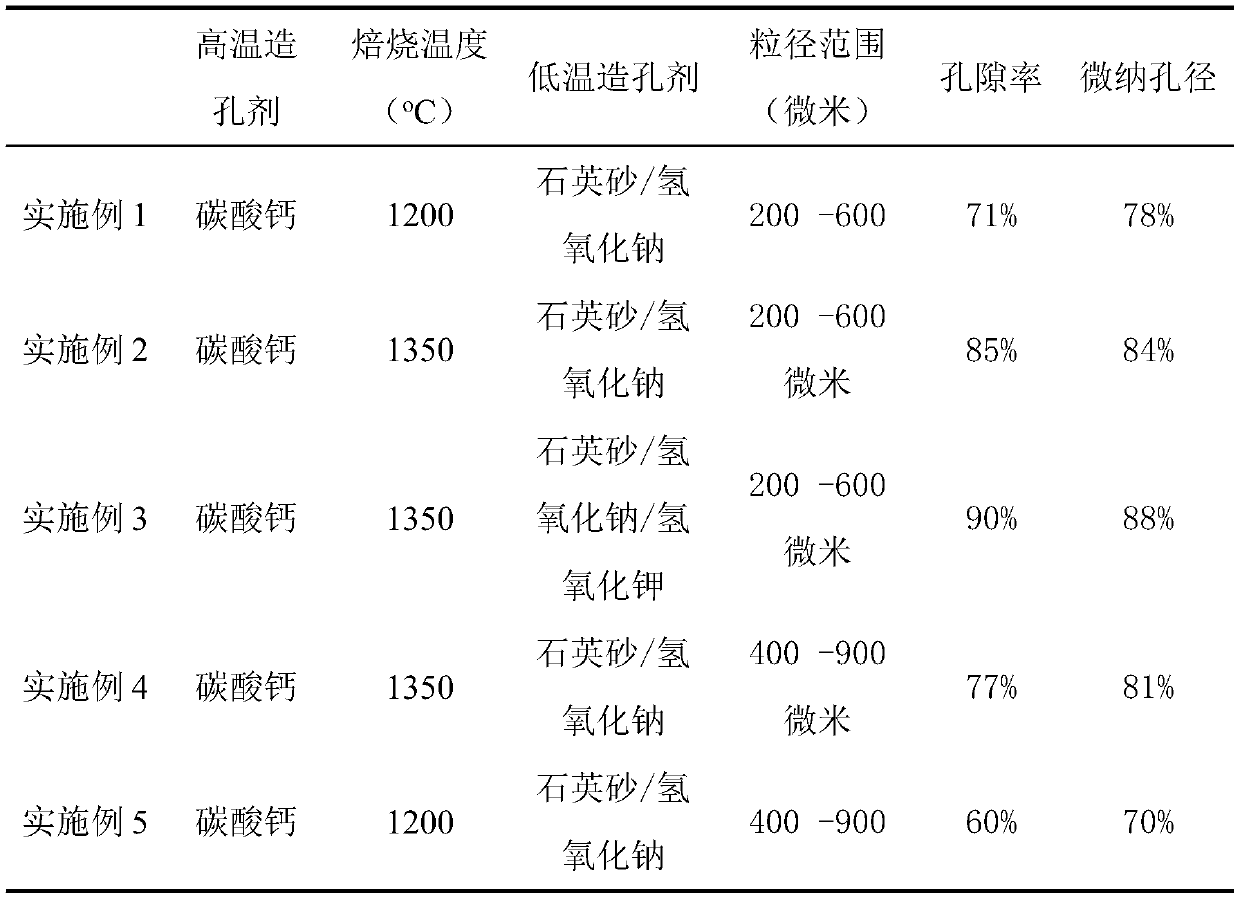

Embodiment 1

[0034] The invention provides a method for preparing porous painted pottery microspheres based on ceramic waste. The ceramic raw materials mainly come from waste building ceramics, sanitary ware ceramics, and craft ceramics. The growth of pores is precisely controlled by two pore-forming techniques to obtain pores. The specific operation steps are as follows:

[0035] (1) Preparation of ceramic micropowder: take waste ceramic raw materials (60-80wt%), wash with water, dry, crush, and ball mill until the particle size is less than 500 microns to obtain ceramic micropowder;

[0036] (2) Preparation of mixed slurry: get the above-mentioned ceramic powder, add 10wt% of water glass, 7wt% of calcium carbonate, 5wt% of quartz sand, 5wt% of iron red, 5wt% of styrene-acrylic resin emulsion and water and stir evenly to obtain mixed slurry ;

[0037] (3) Making ceramic powder blanks: putting the above-mentioned mixed slurry in a certain percentage by weight into a mold, applying a press...

Embodiment 2

[0041] The invention provides a method for preparing porous painted pottery microspheres based on ceramic waste. The ceramic raw materials mainly come from waste building ceramics, sanitary ware ceramics, and craft ceramics. The growth of pores is precisely controlled by two pore-forming techniques to obtain pores. The specific operation steps are as follows:

[0042] (1) Preparation of ceramic micropowder: take waste ceramic raw materials (60-80wt%), wash with water, dry, crush, and ball mill until the particle size is less than 500 microns to obtain ceramic micropowder;

[0043] (2) Preparation of mixed slurry: get the above ceramic powder, add 10wt% of water glass, 8wt% of calcium carbonate, 5wt% of quartz sand, 5wt% of iron red, 6wt% of styrene-acrylic resin emulsion and water and stir evenly to obtain mixed slurry ;

[0044] (3) Making ceramic powder blanks: putting the above-mentioned mixed slurry in a certain percentage by weight into a mold, applying a pressure of 1-2...

Embodiment 3

[0048] The invention provides a method for preparing porous painted pottery microspheres based on ceramic waste. The ceramic raw materials mainly come from waste building ceramics, sanitary ware ceramics, and craft ceramics. The growth of pores is precisely controlled by two pore-forming techniques to obtain pores. The specific operation steps are as follows:

[0049] (1) Preparation of ceramic micropowder: take waste ceramic raw materials (60-80wt%), wash with water, dry, crush, and ball mill until the particle size is less than 500 microns to obtain ceramic micropowder;

[0050] (2) Preparation of mixed slurry: get the above ceramic powder, add water glass 6wt%, calcium carbonate 5wt%, sodium bicarbonate 2wt%, quartz sand 6wt%, cobalt blue 5wt%, fluorocarbon resin emulsion 5wt% and water stirring Uniform, mixed slurry;

[0051] (3) Making ceramic powder blanks: putting the above-mentioned mixed slurry in a certain percentage by weight into a mold, applying a pressure of 1-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com