ALG nano rubber-plastic heat-preservation and sound-insulation plate and processing method thereof

A processing method and sound insulation board technology, which is applied in the field of building materials, can solve the problems of large specific surface area of nanomaterials, low yield of co-extrusion granulation, difficulty in adding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

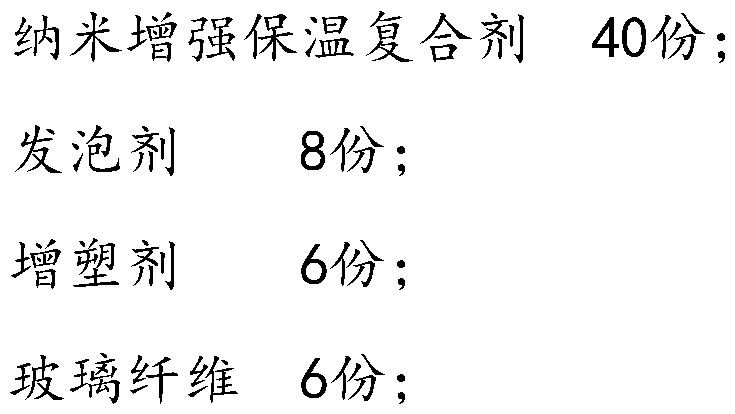

[0052] Embodiment 1: A kind of ALG nano-rubber-plastic thermal insulation sound insulation board, the thickness of thermal insulation sound insulation board is 60mm, the preparation raw material that thermal insulation sound insulation board comprises following parts by weight:

[0053] 45 parts of natural plant rubber, the main component of natural plant rubber is cis-polyisoprene, which is not only environmentally friendly raw material but also has excellent performance;

[0054]

[0055] Among them, the raw material of the nano-reinforced thermal insulation composite agent includes nano-TiO with a weight ratio of 30% 2 And titanium dioxide with a weight ratio of 70%;

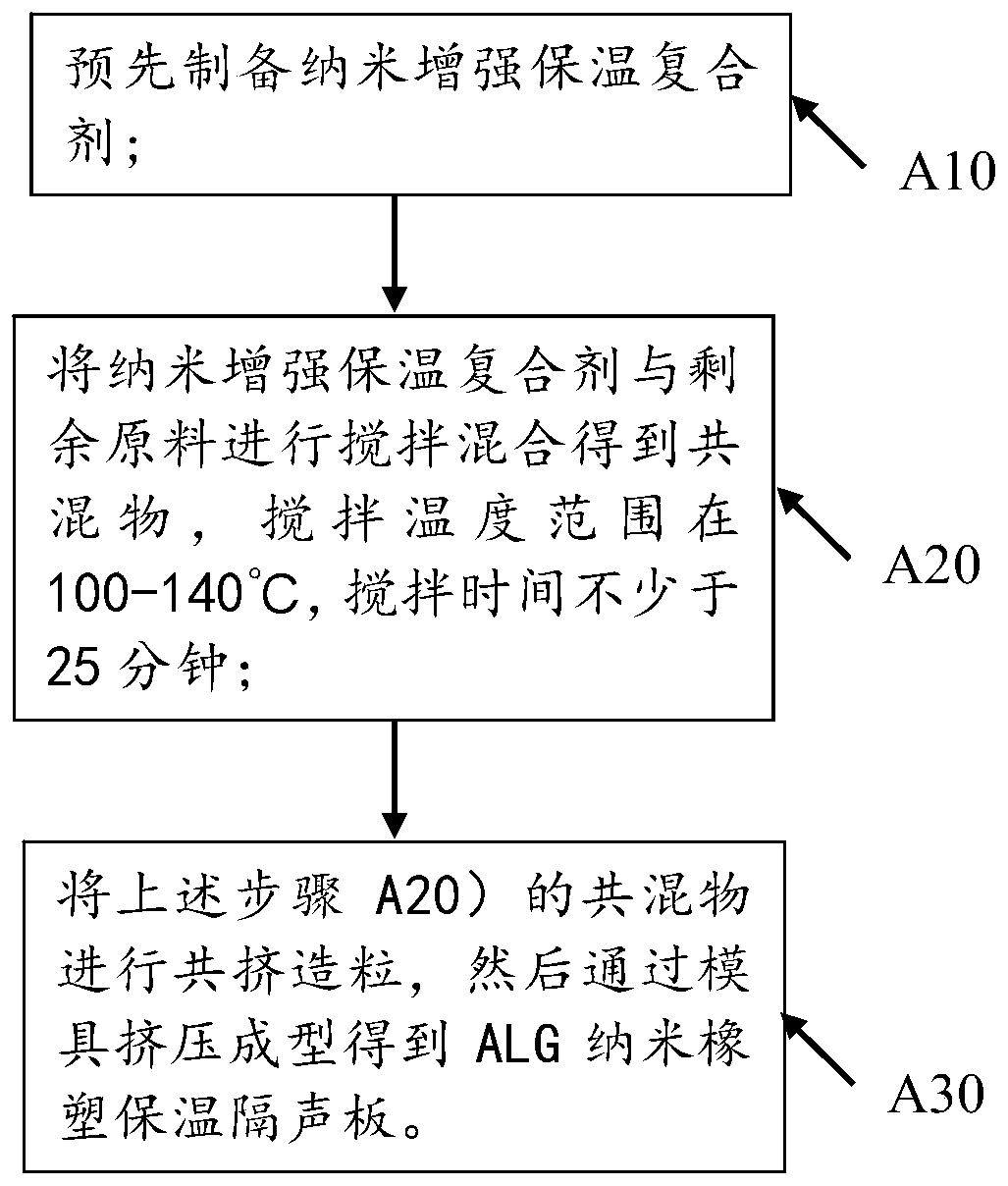

[0056] As mentioned above, the processing method of ALG nanometer rubber and plastic thermal insulation sound insulation board, its operation steps are as follows:

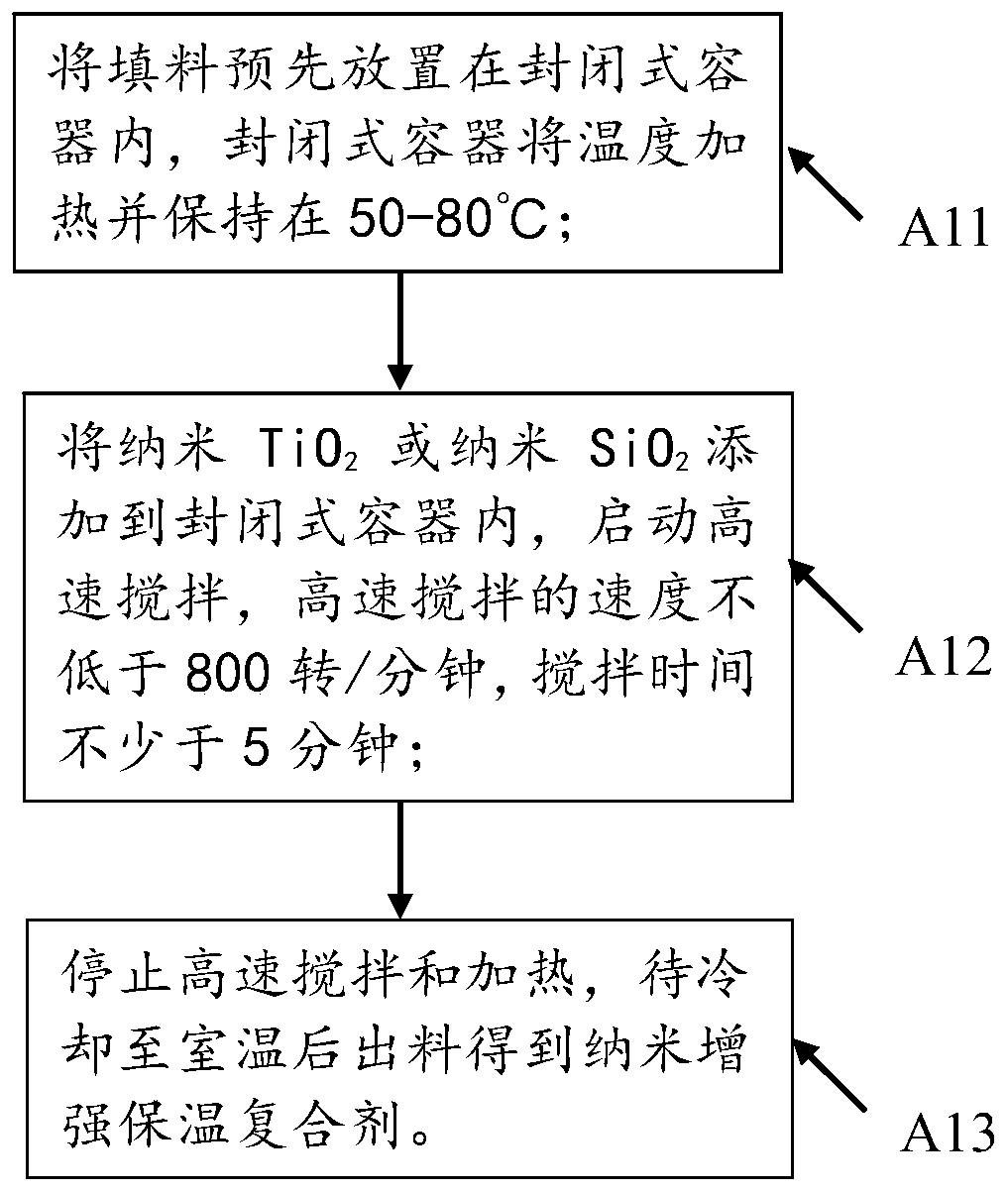

[0057] A10), pre-prepared nano-reinforced heat-insulating compound, wherein, the processing method of nano-reinforced heat-preserved compoun...

Embodiment 2

[0063] Embodiment 2: the remaining technical solutions of this embodiment 2 are the same as embodiment 1, the difference is that in this embodiment 2, nano-SiO is used 2 Nano-TiO in alternative embodiment 1 2 , while using carbon black instead of titanium dioxide in Example 1.

Embodiment 3

[0064] Embodiment 3: the remaining technical solutions of this embodiment 3 are the same as embodiment 2, and the difference is that in this embodiment 3, in step A12), it is 3% carbon black to add in the closed container. Graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com