Preparation technology for high-corrosion-resistance low-carbon steel

A preparation process and low-carbon steel technology, applied in the field of low-carbon steel preparation technology, can solve the problem that the research on the improvement of corrosion resistance of low-carbon steel materials has not been reported yet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

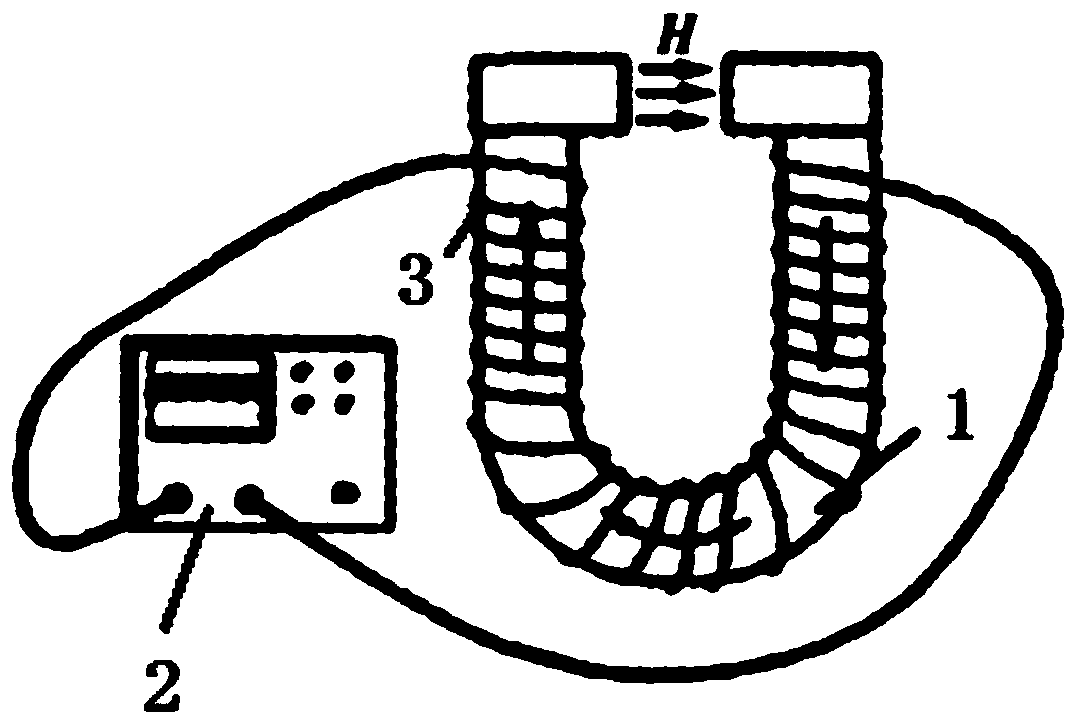

[0020] like figure 1 As shown in the figure, a preparation process of high corrosion-resistant low-carbon steel, adding a magnetic treatment section after the completion of the smelting section of the low-carbon steel billet to obtain a magnetically treated slab, and then rolling the magnetically treated slab. The slab is continuously annealed to obtain a low-carbon steel semi-finished product, and then the surface of the low-carbon steel semi-finished product is subjected to a laser shock process to obtain a low-carbon steel with high corrosion resistance.

[0021] Low carbon steel consists of the following mass percentages: carbon 0.22%, silicon 0.04%, manganese 0.45%, phosphorus 0.03%, sulfur 0.01%, and the balance is iron.

[0022] The direction of the magnetic field of the magnetic treatment section is parallel to the surface of the slab to be magnetically treated.

[0023] In the magnetic treatment section, a low-frequency intermittent magnetic field is used for treatme...

Embodiment 2

[0027] A preparation process of high corrosion-resistant low carbon steel, adding a magnetic treatment section after the smelting section of low carbon steel slab is completed to obtain a magnetically treated slab, and then rolling the magnetically treated slab, and the rolled slab is processed. A continuous annealing process is performed to obtain a low-carbon steel semi-finished product, and then a laser shock process is performed on the surface of the low-carbon steel semi-finished product to obtain a highly corrosion-resistant low-carbon steel.

[0028] Low carbon steel consists of the following mass percentages: carbon 0.06%, silicon 0.09%, manganese 0.05%, phosphorus 0.05%, sulfur 0.03%, and the balance is iron.

[0029] The direction of the magnetic field of the magnetic treatment section is parallel to the surface of the slab to be magnetically treated.

[0030] In the magnetic treatment section, a low-frequency intermittent magnetic field is used for treatment, the fr...

Embodiment 3

[0034] A preparation process of high corrosion-resistant low carbon steel, adding a magnetic treatment section after the smelting section of low carbon steel slab is completed to obtain a magnetically treated slab, and then rolling the magnetically treated slab, and the rolled slab is processed. A continuous annealing process is performed to obtain a low-carbon steel semi-finished product, and then a laser shock process is performed on the surface of the low-carbon steel semi-finished product to obtain a highly corrosion-resistant low-carbon steel.

[0035] Low carbon steel consists of the following mass percentages: carbon 0.18%, silicon 0.06%, manganese 0.3%, phosphorus 0.04%, sulfur 0.02%, and the balance is iron.

[0036] The direction of the magnetic field of the magnetic treatment section is parallel to the surface of the slab to be magnetically treated.

[0037] In the magnetic treatment section, a low-frequency intermittent magnetic field is used for treatment, the fre...

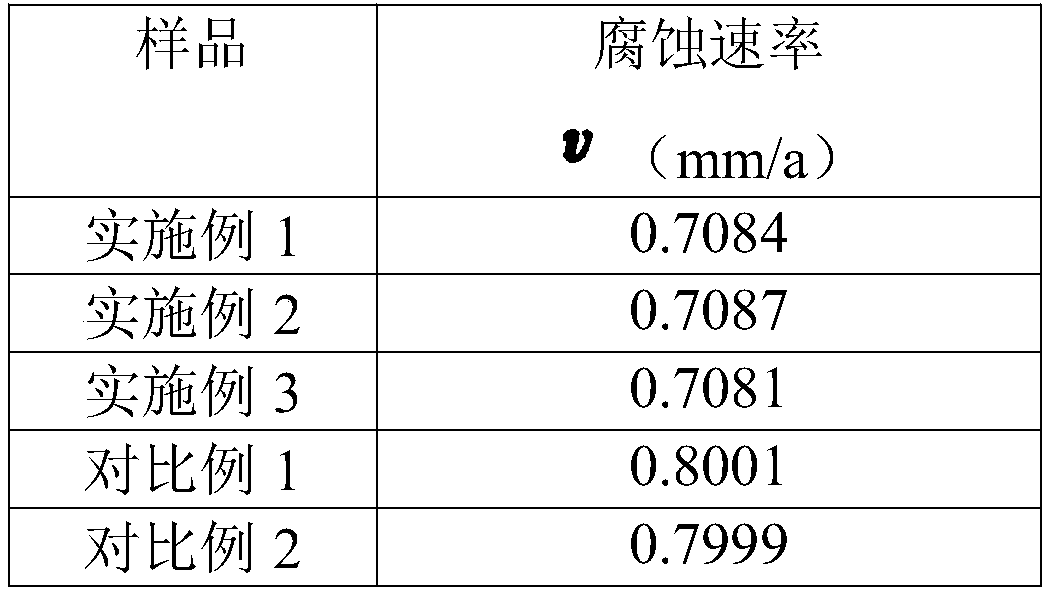

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com