Anti-corrosion arrangement method for water cooling wall of waste incineration waste heat boiler

A waste heat boiler and waste incineration technology, which is applied to boiler water pipes, steam generation methods using heat carriers, steam boilers, etc., can solve the problems of increased corrosion risk of high-temperature heating surfaces, and achieve the effect of avoiding high-temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

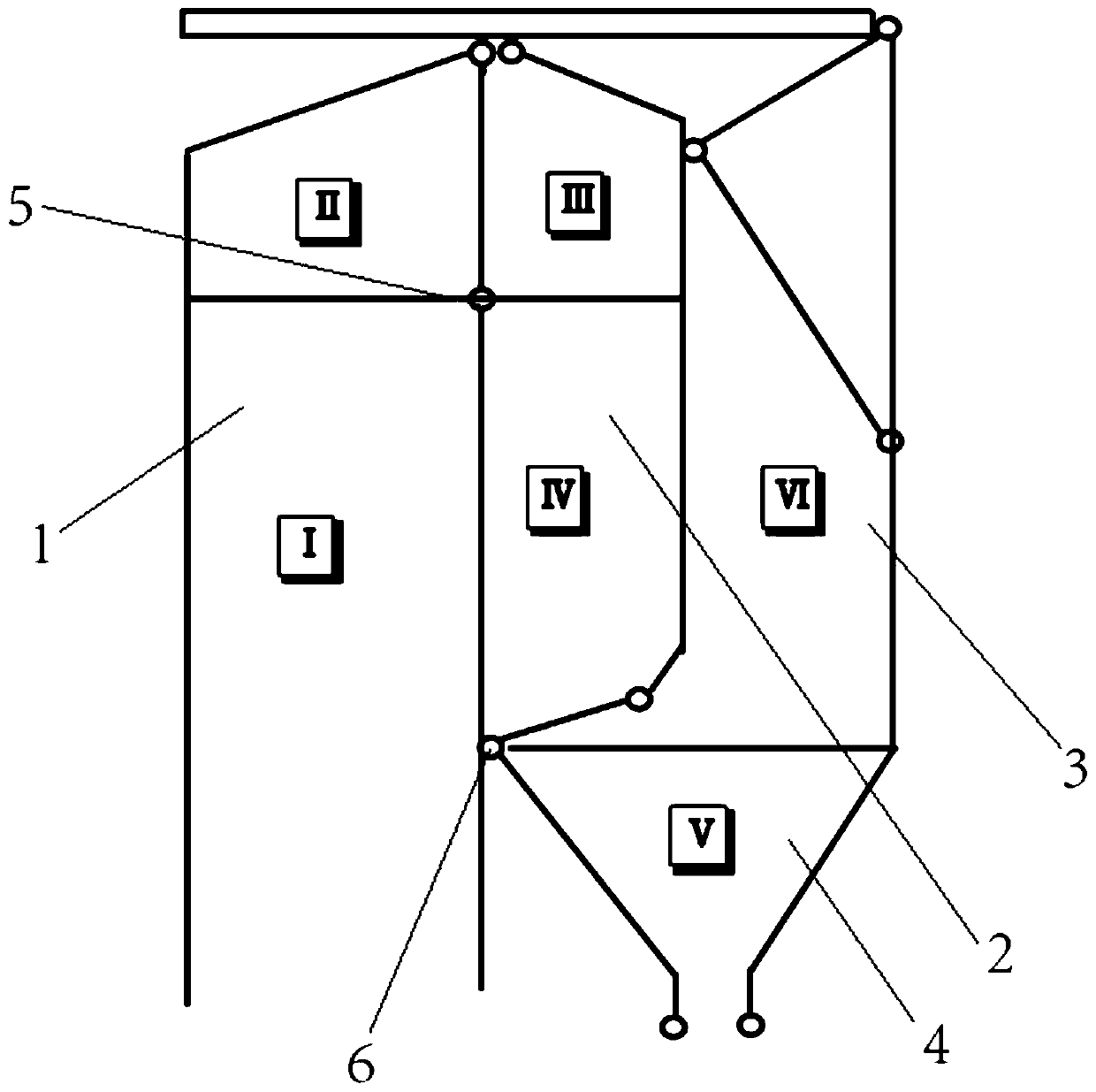

[0019] figure 1 Area Ⅰ (that is, the area below the smokestack 5 of the flue 1 exit in flue 1), area Ⅱ (that is, the area above 5 of the flue 1 exit chimney in flue 1), area Ⅲ (that is, the area of flue 2 2 The water-cooled heating surface of the water-cooled wall structure located in the area above the flue-exit chimney 5), area V (that is, the ash hopper 4 area) is refractory pouring. figure 1 The water-cooled heating surface of the water-cooled wall structure in area IV (that is, the straight section of flue two 2) and area VI (that is, flue three 3) is surfacing.

Embodiment 2

[0021] figure 1 In the area I, area II, area III, and area V, the water-cooled heating surface of the water-cooled wall structure is cast refractory. Considering that the pouring in the roof area is easy to fall off, the area II and area III are surfacing first, and then refractory pouring is performed on the basis of the surfacing layer, which can further prolong the service life of the flue 1 and flue 2 ceiling pipes. Simultaneously figure 1 The surfacing welding of the water-cooled heating surface of the water-cooled wall structure in area IV and area VI.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com