A low-temperature refrigerator directly driven by a free-piston engine

A technology of piston engine and cryogenic refrigerator, applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve problems such as energy waste, and achieve the effect of facilitating subsequent storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

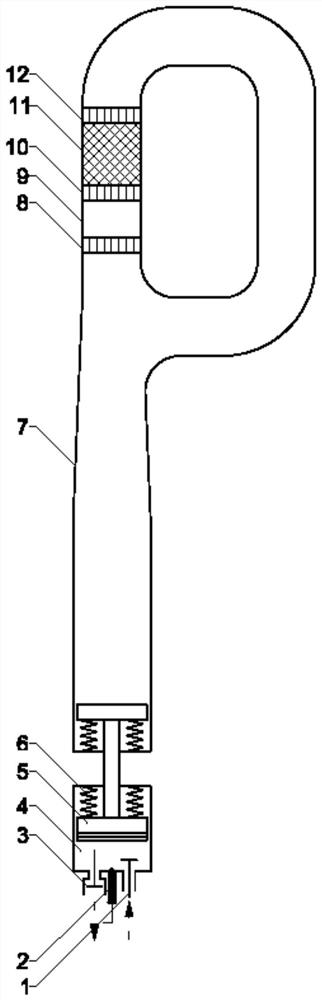

Embodiment 1

[0026] see figure 1 , The cryogenic refrigerator directly driven by the free piston engine of this embodiment is a traveling wave thermoacoustic cryogenic refrigerator, comprising: intake valve 1, spark plug 2, exhaust valve 3, combustion chamber 4, opposed double pistons 5, return spring 6. Resonant tube 7, secondary cooler 8, thermal buffer tube 9, cold end heat exchanger 10, regenerator 11, main cooler 12. Fuel gas and auxiliary gas enter the combustion chamber 4 of the free-piston engine from the intake valve 1, ignite through the spark plug 2 and do work to push the opposed dual pistons 5 to move, and the exhaust gas is discharged through the exhaust valve 3. The periodic movement of the opposed double pistons 5 generates a pressure wave at one end of the resonant tube 7 of the traveling wave thermoacoustic cryogenic refrigerator, and the gas working medium in the regenerator 11 is absorbed from the side of the cold end heat exchanger 10 under the action of the pressure w...

Embodiment 2

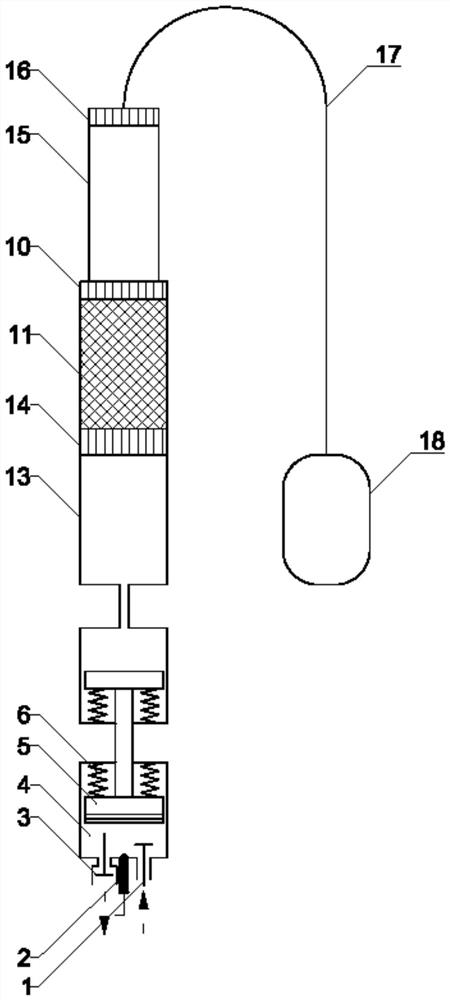

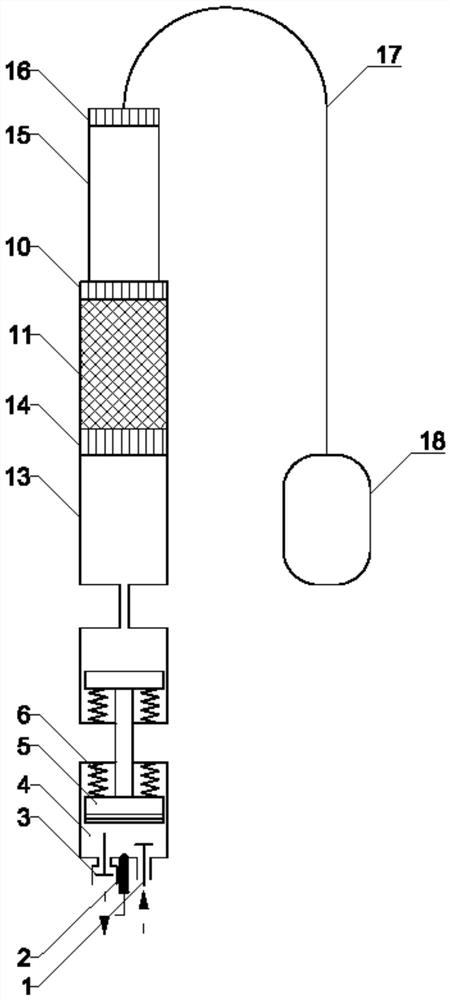

[0028] see figure 2 , the low-temperature refrigerator directly driven by the free-piston engine of the present embodiment is a Stirling pulse tube cryogenic refrigerator, comprising: intake valve 1, spark plug 2, exhaust valve 3, combustion chamber 4, opposed double pistons 5, recovery Spring 6, transfer pipe 13, regenerator hot end heat exchanger 14, regenerator 11, cold end heat exchanger 10, pulse tube 15, pulse tube hot end heat exchanger 16, inertia tube 17, gas storage 18. Fuel gas and auxiliary gas enter the combustion chamber 4 of the free-piston engine from the intake valve 1, ignite through the spark plug 2 and do work to push the opposed dual pistons 5 to move, and the exhaust gas is discharged through the exhaust valve 3. The periodic movement of the opposed double pistons 5 generates a pressure wave at one end of the transfer tube of the Stirling pulse tube cryogenic refrigerator, and the gas working medium in the regenerator 11 passes through the heat exchanger...

Embodiment 3

[0030] The low-temperature refrigerator directly driven by the free-piston engine of this embodiment is a Stirling low-temperature refrigerator, comprising: intake valve 1, spark plug 2, exhaust valve 3, combustion chamber 4, opposed double pistons 5, return spring 6, Compression chamber, push piston, expansion chamber, cold end heat exchanger 10, regenerator 11, water cooler, connecting rod, elastic air chamber, push piston spring. Fuel gas and auxiliary gas enter the combustion chamber 4 of the free-piston engine from the intake valve 1, ignite through the spark plug 2 and do work to push the opposed dual pistons to move, and the exhaust gas is discharged through the exhaust valve 3. The pressure waves generated by the periodic motion of the opposed double pistons 5 work together with the elastic air cavity and the pushing piston spring to drive the Stirling cryogenic refrigerator to work. At the beginning, the pushing piston is at the top dead center, and the opposite doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com