Optical frequency comb signal generating device and method

A technology of signal generation and optical frequency comb, which is applied in the direction of laser devices, semiconductor laser devices, devices for controlling laser output parameters, etc., can solve the problems of integration of electroabsorption modulation lasers and semiconductor optical amplifiers, large carrier noise, The carrier phase relationship is not obvious, etc., to achieve the effect of simple structure, wide signal spectrum and large number of comb teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

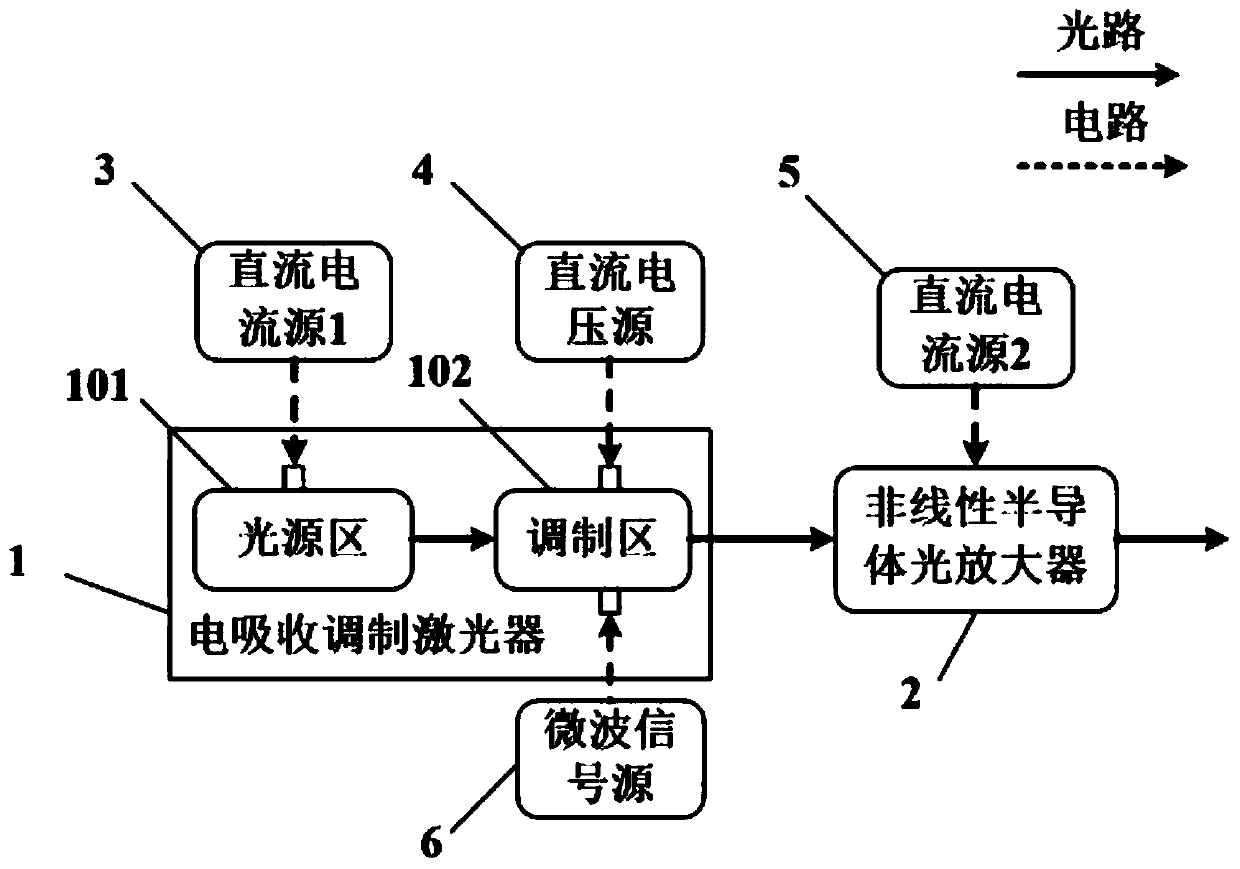

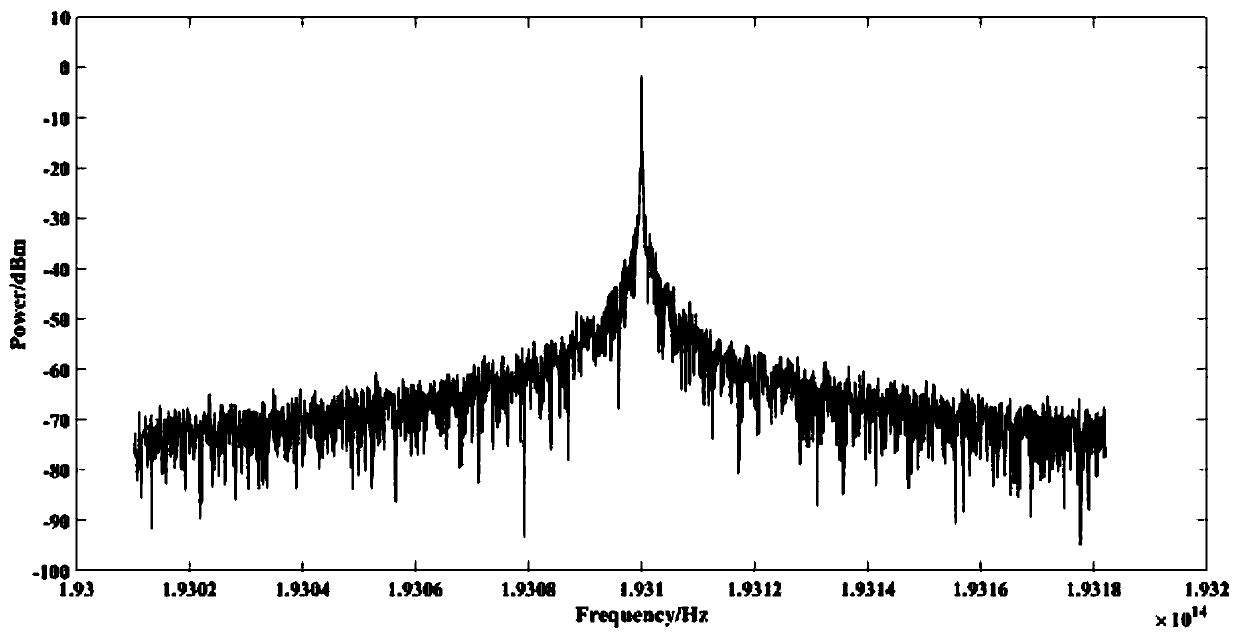

[0035] In this example, set the repetition frequency f of the optical frequency comb to be generated s Set the forward current output by the DC current source 1 to 35mA to make the light source area of the electro-absorption modulated laser work normally, and the center frequency of the output optical signal f 0 It is 193.4THz, and then input to the modulation area of the electro-absorption modulation laser, where the DC bias terminal and the RF input end of the electro-absorption modulation laser are not loaded with any voltage signal and microwave signal, and from the modulation area of the electro-absorption modulation laser The output optical signal passes through the non-linear semiconductor optical amplifier, and its bias end has a forward current of 50 mA. At this time, the non-linear semiconductor optical amplifier works in the linear region and only amplifies the optical power, and then the output optical signal is observed by a spectrometer. Such as figure 2 Show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com