Preparation method of high-performance ZIF-8-containing nanofiltration membrane based on two-step addition of sodium polystyrene sulfonate

A technology of sodium polystyrene sulfonate and ZIF-8, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of membrane performance decline, poor dispersion, agglomeration, etc. Ease of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

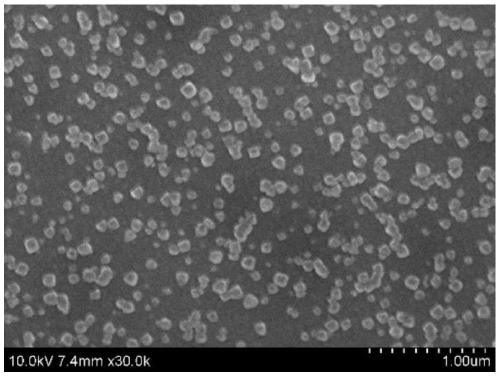

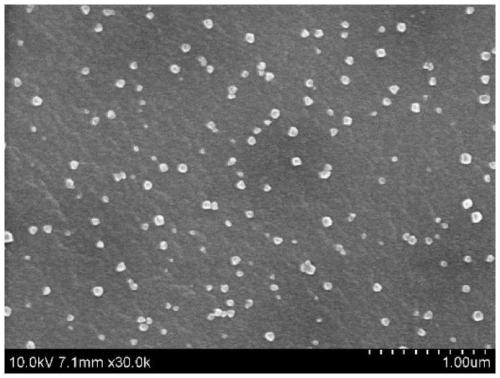

Image

Examples

Embodiment 1

[0029] Using 30KDa polyacrylonitrile ultrafiltration flat membrane as the base membrane, fix the 10cm×10cm base membrane on the glass plate, and soak the upper surface in 50mL of 0.6% PSS aqueous solution, take it out after 20h, and remove the membrane with a rubber roller Excess water on the surface; soak the upper surface of the membrane in 50mL zinc nitrate solution with a concentration of 0.018mol / L, take it out after 20h, remove the excess water on the surface of the membrane with a rubber roller; soak the upper surface of the membrane in 50mL Hmim with a concentration of 0.28mol / L, PSS concentration of 0.6% in the mixed aqueous solution, take it out after 20h, wash it thoroughly with deionized water, and let it stand for 15min at 60℃; soak the upper surface of the membrane in 50mL of 2% PIP aqueous solution, and take it out after 2min , Use a rubber roller to remove excess water on the membrane surface; immerse the upper surface of the membrane in 50 mL of 0.2% TMC n-hexa...

Embodiment 2

[0031] Using 30KDa polyacrylonitrile ultrafiltration flat membrane as the base membrane, fix the 10cm×10cm base membrane on the glass plate, soak the upper surface of the membrane in 50mL zinc nitrate solution with a concentration of 0.018mol / L, and take it out after 20h. The rubber roller removes excess water on the surface of the membrane; soak the upper surface of the membrane in 50mL Hmim aqueous solution with a concentration of 0.28mol / L, take it out after 20h, wash it with deionized water, and let it stand at 60℃ for 15min; soak the upper surface of the membrane In 50mL of 2% concentration of PIP aqueous solution, take out after 2 minutes, remove excess water on the surface of the film with a rubber roller; soak the top surface of the film in 50mL of 0.2% concentration of TMC n-hexane solution, take out after 1 minute, at 65℃ The composite nanofiltration membrane containing ZIF-8 was prepared by heat treatment for 2 min. The performance of the membrane was tested with a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com