Preparation method and application of low-load Pd/hollow carbon sphere oxygen reduction electrocatalyst

A technology of hollow carbon spheres and electrocatalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the cumbersome preparation process, difficult industrial production, particle agglomeration and other problems, to achieve the effect of uniform shell thickness, promotion of adsorption and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

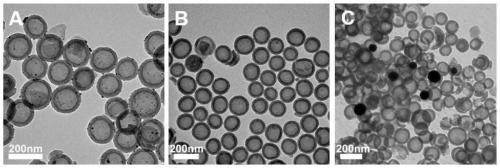

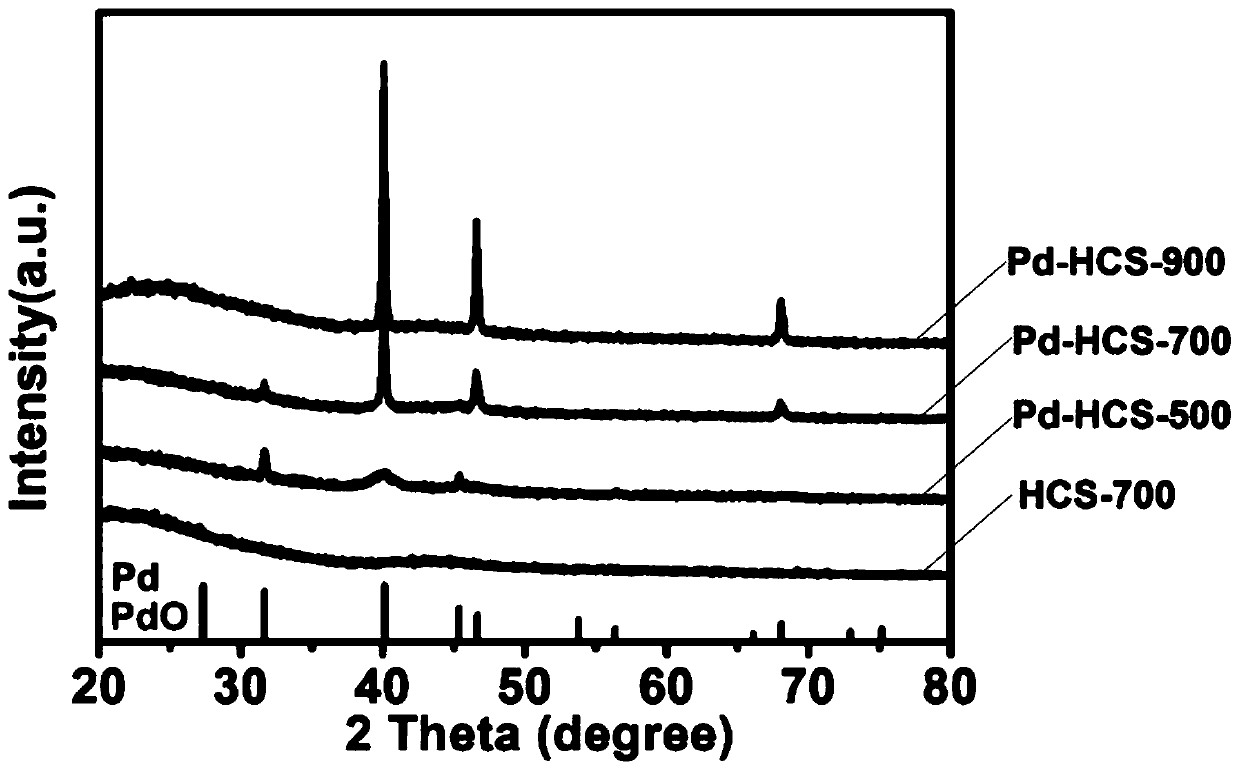

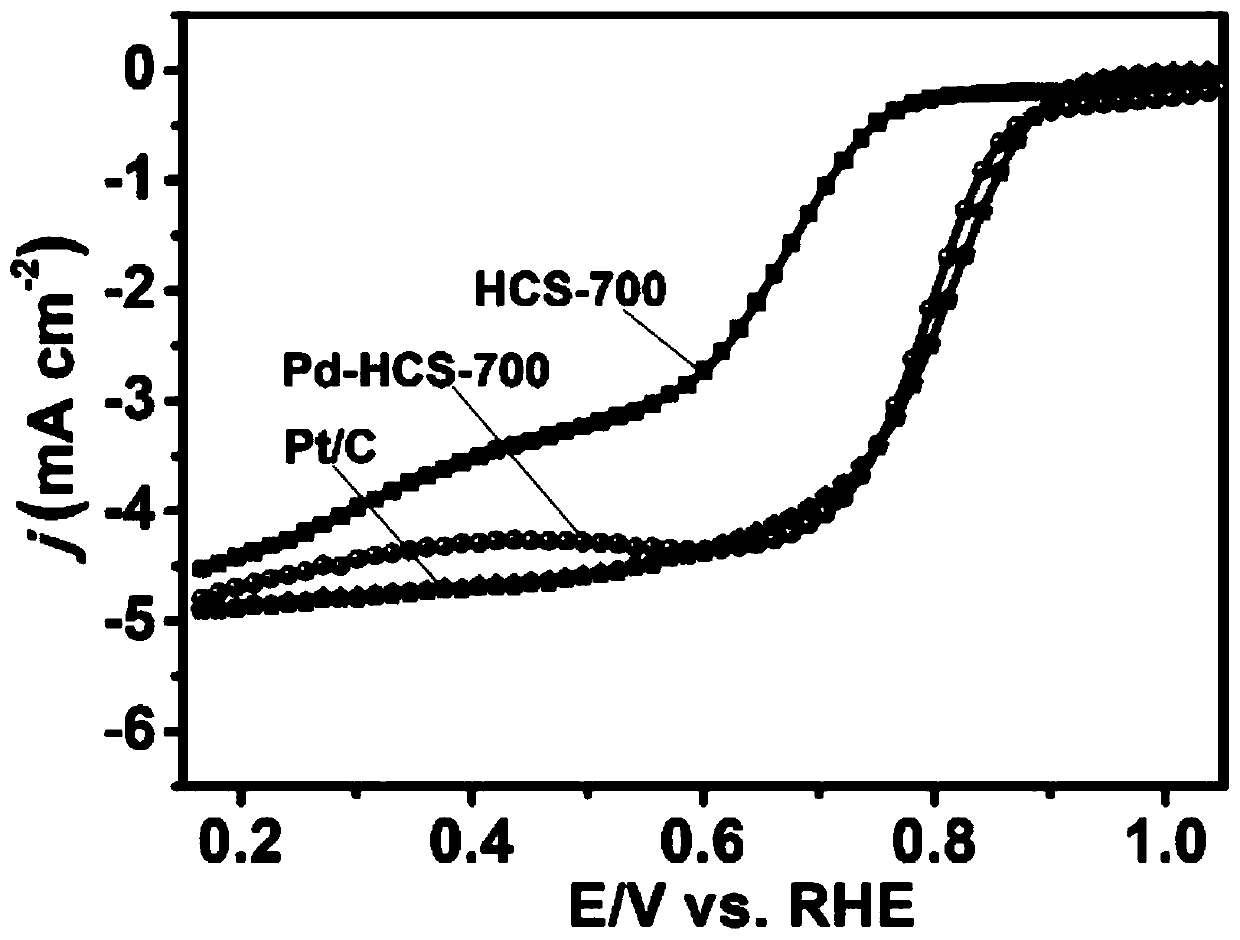

[0035] Embodiment 1, preparation of hollow carbon sphere nanomaterial (HCS-700)

[0036] In order to compare the performance difference between the Pd-free hollow carbon sphere oxygen reduction electrocatalyst and the low-loaded Pd / hollow carbon sphere oxygen reduction electrocatalyst, a hollow carbon sphere (HCS) was first prepared, and the specific preparation method included the following steps:

[0037] (a) Hydrothermal process: Weigh 54mg template agent PluronicP123 and 90mg sodium oleate to prepare aqueous solutions A with concentrations of 0.375mmol / L and 12mmol / L, respectively. Then weigh 231mg of 2,4-dihydroxybenzoic acid (DA) and 88mg of hexamethylenetetramine (HMT) to prepare aqueous solutions with concentrations of 20mmol / L and 8.3mmol / L, respectively, stir and dissolve for 30min to obtain solution B. Then, during the stirring process, the solution A was slowly added into the solution B, and the stirring was continued for 30 min to obtain the micellar solution C. ...

Embodiment 2

[0039] Embodiment 2, preparation of low loading Pd / hollow carbon sphere oxygen reduction electrocatalyst (Pd-HCS-500)

[0040] A kind of preparation method of low loading Pd / hollow carbon sphere nano material, comprises the steps:

[0041] (a) Hydrothermal process: Weigh 54mg template agent PluronicP123 and 90mg sodium oleate to prepare aqueous solutions A with concentrations of 0.375mmol / L and 12mmol / L, respectively. Then weigh 231mg of 2,4-dihydroxybenzoic acid (DA) and 88mg of hexamethylenetetramine (HMT) to prepare aqueous solutions with concentrations of 20mmol / L and 8.3mmol / L, respectively, stir and dissolve for 30min to obtain solution B. Then, during the stirring process, the solution A was slowly added into the solution B, and the stirring was continued for 30 min to obtain the micellar solution C. Then move the solution C into a polytetrafluoroethylene reaction kettle and place it in an oven, keep it at 160°C for 2 hours according to the heating rate program of 1°C / ...

Embodiment 3

[0044] Embodiment 3, preparation of low loading Pd / hollow carbon sphere oxygen reduction electrocatalyst (Pd-HCS-700)

[0045] A preparation method of a low-loaded Pd / hollow carbon sphere oxygen reduction electrocatalyst, comprising the steps of:

[0046] (a) Hydrothermal process: Weigh 54mg template agent PluronicP123 and 90mg sodium oleate to prepare aqueous solutions A with concentrations of 0.375mmol / L and 12mmol / L, respectively. Then weigh 231mg of 2,4-dihydroxybenzoic acid (DA) and 88mg of hexamethylenetetramine (HMT) to prepare aqueous solutions with concentrations of 20mmol / L and 8.3mmol / L, respectively, stir and dissolve for 30min to obtain solution B. Then, during the stirring process, the solution A was slowly added into the solution B, and the stirring was continued for 30 min to obtain the micellar solution C. Then move the solution C into a polytetrafluoroethylene reaction kettle and place it in an oven, keep it at 160°C for 2 hours according to the heating rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com