Zirconium-aluminum hollow sphere prepared by taking FCC waste catalyst as raw material, and production process and application of zirconium-aluminum hollow sphere

A waste catalyst and hollow sphere technology is used in the preparation of zirconium-aluminum hollow spheres using FCC waste catalysts as raw materials and its production process and application fields, which can solve problems such as secondary pollution and achieve high spheroidization rate, low thermal conductivity, and electrical conductivity. Good insulation and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

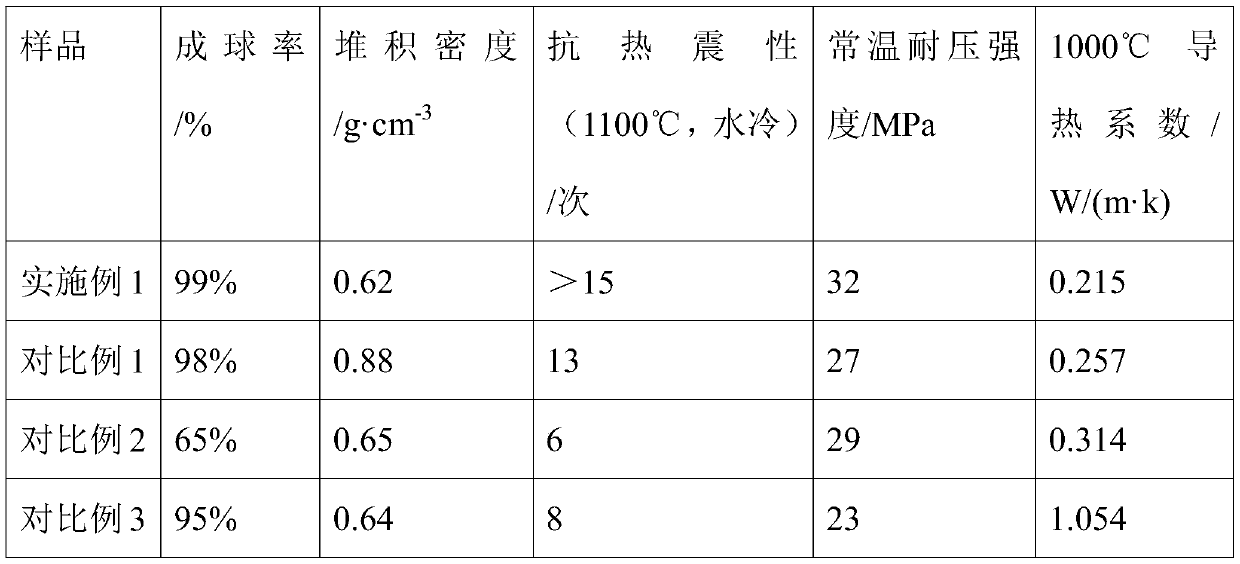

Examples

Embodiment 1

[0065] A kind of use FCC spent catalyst as raw material to prepare zirconium-aluminum hollow sphere, and this hollow sphere is made of the following raw materials by weight:

[0066] 75 parts of FCC waste catalyst, 2.5 parts of coal gangue, 4 parts of zirconium dioxide, 15 parts of aluminum oxide, 1.5 parts of silicon dioxide, and 2 parts of sodium carboxymethyl cellulose.

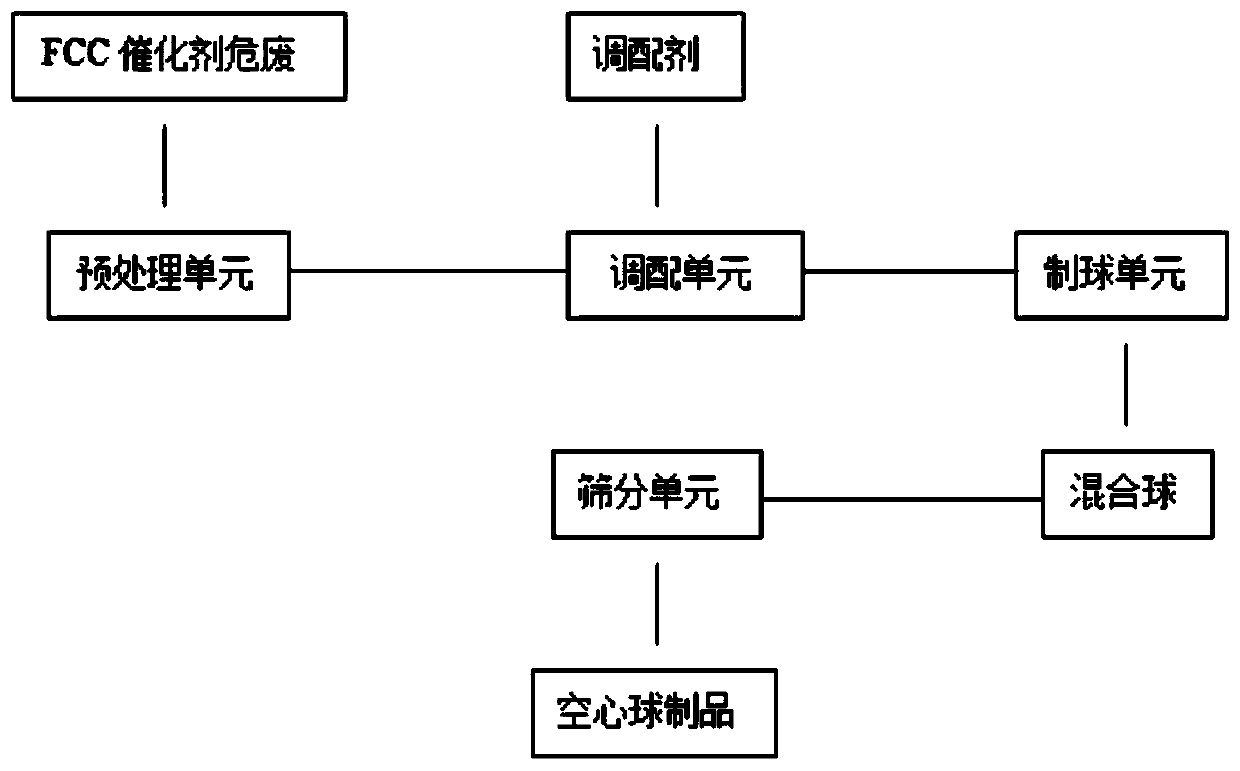

[0067] The preparation method of the zirconium-aluminum hollow spheres, the method comprises the following steps, the flow process is as follows: figure 1 Shown:

[0068] (1) Calcination pretreatment of FCC waste catalyst:

[0069] Put the spent FCC catalyst into a pulverizer for pulverization, and the pulverization particle size is less than or equal to 1mm;

[0070] Put the crushed FCC waste catalyst into a rotary kiln for closed calcination treatment, the gas environment is 15v / v% HCl gas, and calcination treatment at 1500°C for 1.5h;

[0071] (2) put coal gangue into a gas-fired kiln for closed calc...

Embodiment 2

[0082] A kind of use FCC spent catalyst as raw material to prepare zirconium-aluminum hollow sphere, and this hollow sphere is made of the following raw materials by weight:

[0083] 78.5 parts of FCC waste catalyst, 2 parts of coal gangue, 3 parts of zirconium dioxide, 14 parts of aluminum oxide, 1 part of silicon dioxide, and 1.5 parts of sodium carboxymethyl cellulose.

[0084] The preparation method of the zirconium-aluminum hollow spheres comprises the following steps:

[0085] (1) Calcination pretreatment of FCC waste catalyst:

[0086] Put the spent FCC catalyst into a pulverizer for pulverization, and the pulverization particle size is less than or equal to 1mm;

[0087] Put the crushed FCC waste catalyst into a rotary kiln for closed calcination treatment, the gas environment is 20v / v% HCl gas, and calcination treatment at 1200°C for 2h;

[0088] (2) put coal gangue into a gas kiln for closed calcining treatment, the gas environment is 20v / v% HCl gas, and calcining ...

Embodiment 3

[0099] A kind of use FCC spent catalyst as raw material to prepare zirconium-aluminum hollow sphere, and this hollow sphere is made of the following raw materials by weight:

[0100] 74.5 parts of FCC waste catalyst, 3 parts of coal gangue, 4 parts of zirconium dioxide, 16 parts of aluminum oxide, 1.5 parts of silicon dioxide, and 1 part of sodium carboxymethyl cellulose.

[0101] The preparation method of the zirconium-aluminum hollow spheres comprises the following steps:

[0102] (1) Calcination pretreatment of FCC waste catalyst:

[0103] Put the spent FCC catalyst into a pulverizer for pulverization, and the pulverization particle size is less than or equal to 1mm;

[0104] Put the pulverized FCC waste catalyst into a rotary kiln for closed calcination treatment, the gas environment is 18v / v% HCl gas, and calcination treatment at 1500°C for 3h;

[0105] (2) put coal gangue into a gas kiln for closed calcining treatment, the gas environment is 18v / v% HCl gas, and calcini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com