High-wear-resistance damp-proof coating composition as well as preparation method and application thereof

A technology with high wear resistance and composition, applied in anti-corrosion coatings, coatings, polyurea/polyurethane coatings, etc., can solve the problems of inability to spray electronic components, moisture-proof agent waterproof and moisture-proof restrictions, etc., to achieve safety and environmental protection in the preparation and use process , low surface tension, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Add 100g TEMAc-6 (0.23mol), 0.3g HEMA (0.0023mol), 0.5g AIBN, 100g 7300 into a 500ml three-necked flask, N 2 After the replacement, react at 80°C for 6 hours to obtain a fluorine-containing polymer stock solution. The weight-average molecular weight of the fluorine-containing polymer was 31,000.

[0045] Add 0.22g of curing agent TDI and 9930g of 7200 to the fluoropolymer stock solution, and stir evenly in a mixing tank to obtain a coating composition.

[0046] The coating composition was dripped onto the substrate by means of drop coating, and after curing at room temperature for 72 hours, a coating was obtained. The coating properties are listed in Table 1. The coating formed by the coating composition has good hydrophobicity, hardness and wear resistance. The carbon steel corrosion test shows that the moisture-proof and water-proof effect of the coating composition coating on the carbon steel sheet has a good retarding effect on the corrosion of the carbon steel s...

Embodiment 2

[0051] Add 100g TEMAc-6 (0.23mol), 15g HEMA (0.12mol), 10g AIBN, 1000g 7200 into a 1000ml three-necked flask, N 2 After replacement, react at 70°C for 24 hours to obtain a fluoropolymer stock solution. The weight average molecular weight of the fluorine-containing polymer is 5,000.

[0052] Add 25.7g of curing agent IPDI and 150g of 7200 to the fluorine-containing polymer stock solution, and stir evenly in a mixing tank to obtain a coating composition.

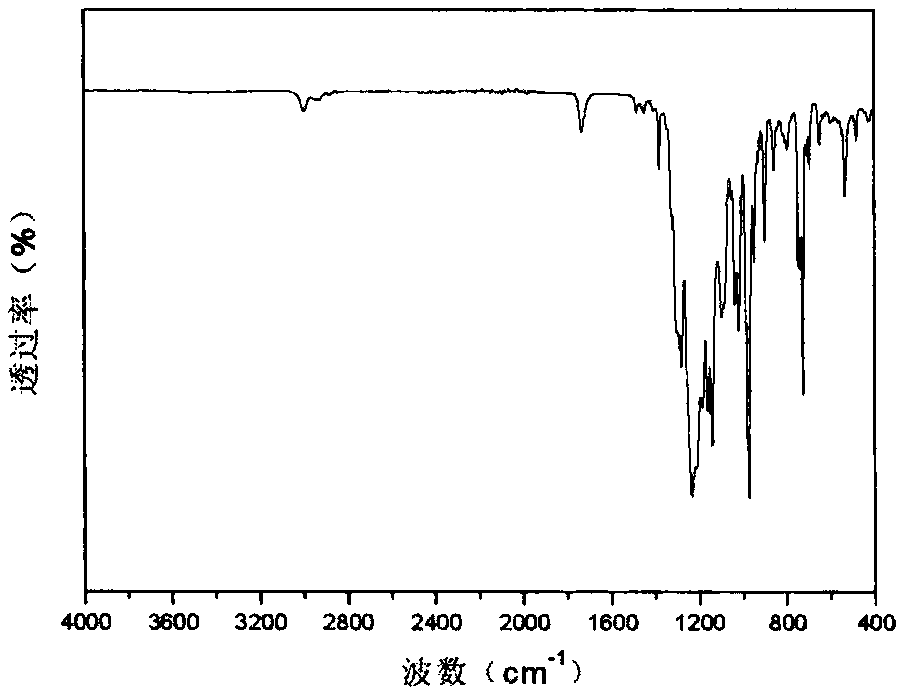

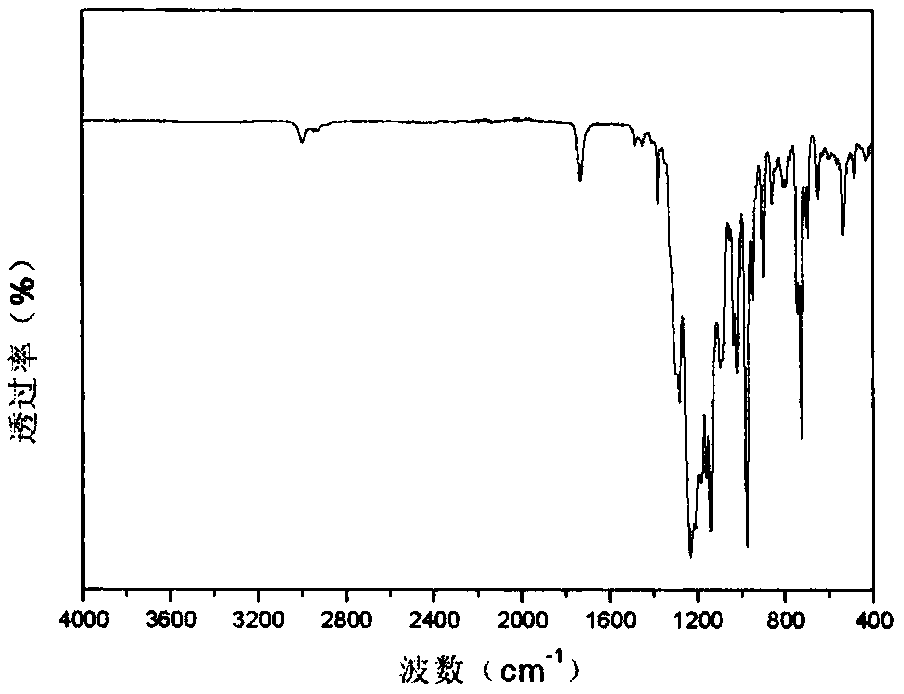

[0053] The coating composition is sprayed onto the substrate by spraying, and after drying, it is cured at 200° C. for 0.01 h to obtain a coating. The coating properties are listed in Table 1. The FT-IR spectrum of the coating is as follows figure 2 As shown, it can be seen that the coating is a fluorine-containing copolymer.

Embodiment 3

[0055] Add 100g TEMAc-6 (0.24mol), 6.9g HPMA (0.05mol), 2g BPO, 200g 7100 into a 500ml three-necked flask, N 2 After replacement, react at 60°C for 24 hours to obtain a fluoropolymer stock solution. The weight-average molecular weight of the fluorine-containing polymer is 55,000.

[0056] Add 10.6g of curing agent IPDI, 2186g of 7100 and 243g of HFE-449 to the stock solution of fluoropolymer, and stir evenly in a mixing tank to obtain a coating composition.

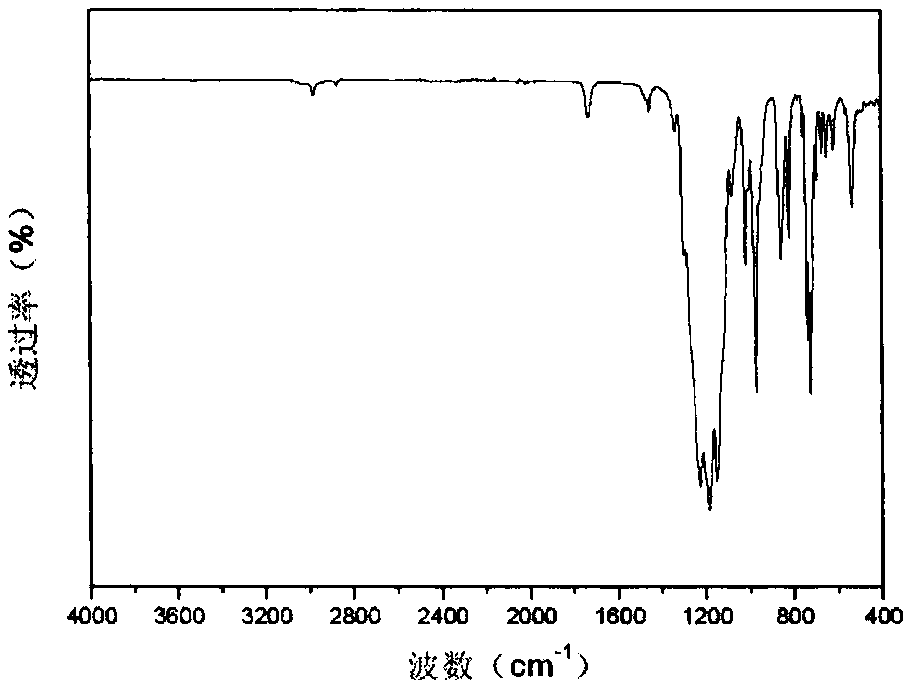

[0057] The coating composition is sprayed onto the substrate by spraying, and after drying, it is cured at 120° C. for 2 hours to obtain a coating. The coating properties are listed in Table 1. The FT-IR spectrum of the coating is as follows image 3 As shown, it can be seen that the coating is a fluorine-containing copolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com