Hall thruster with double magnetic screens

A technology of Hall thruster and magnetic shield, which is applied in the direction of thrust reverser, machine/engine, and utilization of plasma, and can solve the problems of electron-wall interaction, wall energy deposition, thermal instability energy, loss, etc., to avoid Discharge thermal instability, electronic current suppression, robustness and longevity assurance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

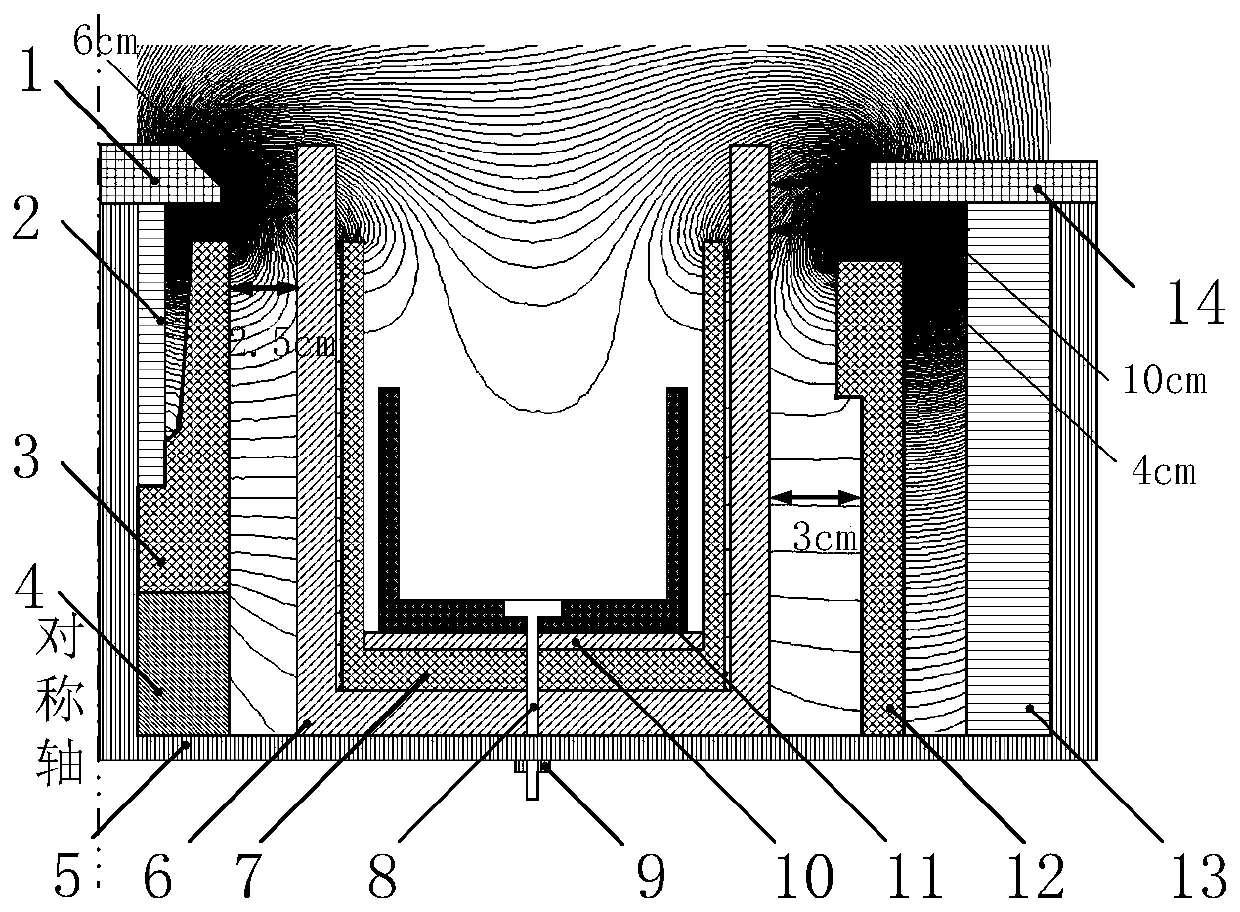

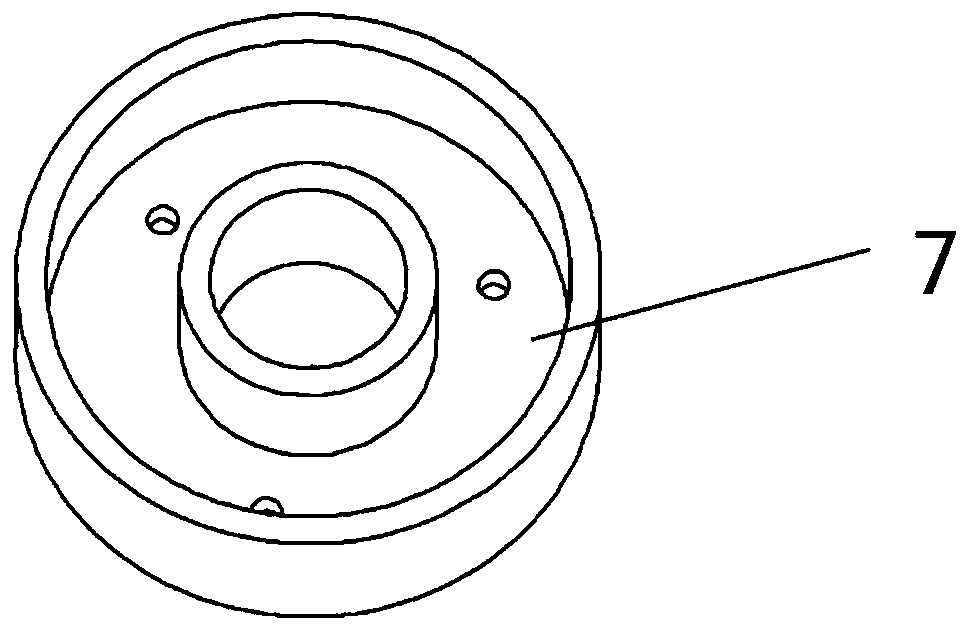

[0017] combined with Figure 1 to Figure 2 Illustrate the specific embodiment of the present invention: the Hall thruster of a kind of double magnetic screen of the present invention, as figure 1 As shown, it includes inner magnetic pole 1, inner excitation coil 2, inner magnetic shield 3, additional coil 4, bottom plate 5, ceramic channel 6, additional magnetic shield 7, gas distributor 8, fixing nut 9, ceramic gasket 10, anode 11 , the outer magnetic shield 12, the outer excitation coil 13 and the outer magnetic pole 14, the base plate 5 is a circular plate shape, the center of the circular plate shape is provided with a column, and four cylinders are evenly distributed on the circumference of the base plate 5; the ring-shaped The additional coil 4 is set on the bottom of the column of the base plate 5, the inner magnetic shield 3 is set on the column of the base plate 5 and is located above the additional coil 4, the inner excitation coil 2 is wound on the column of the bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com