High-strength magnesium alloy-based degradable bone fracture internal fixation plate and preparation method thereof

A technology of magnesium alloy and fixed plate, which is applied in the medical field, can solve the problems that the degradation efficiency cannot be effectively controlled, the magnesium alloy fixed plate is heavy, and the recovery speed of the wound is slow, so as to avoid the deformation of the positioning structure and the insufficient strength of the positioning structure, and improve the reliability. Sexual safety, flexible and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

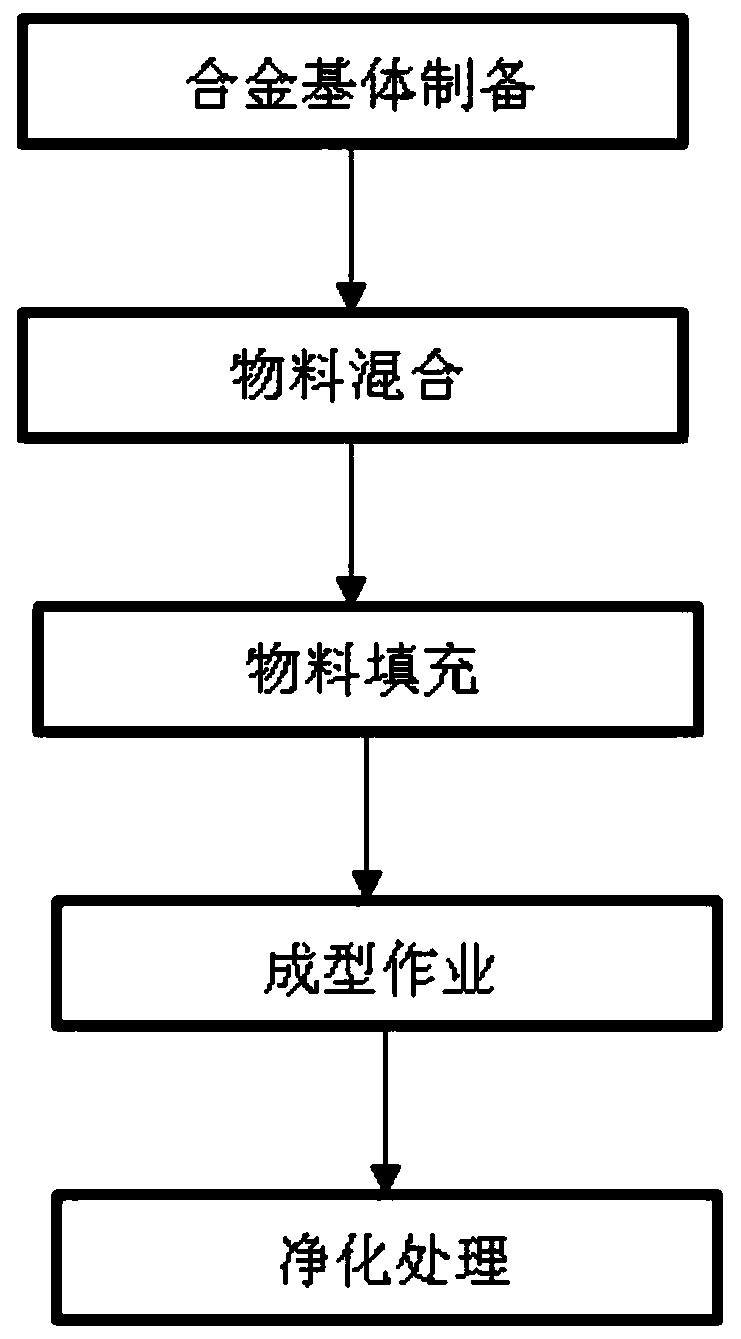

[0033] Such as figure 2 As shown, a method for preparing a high-strength magnesium alloy-based degradable internal fixation plate for bone trauma, comprising the following steps:

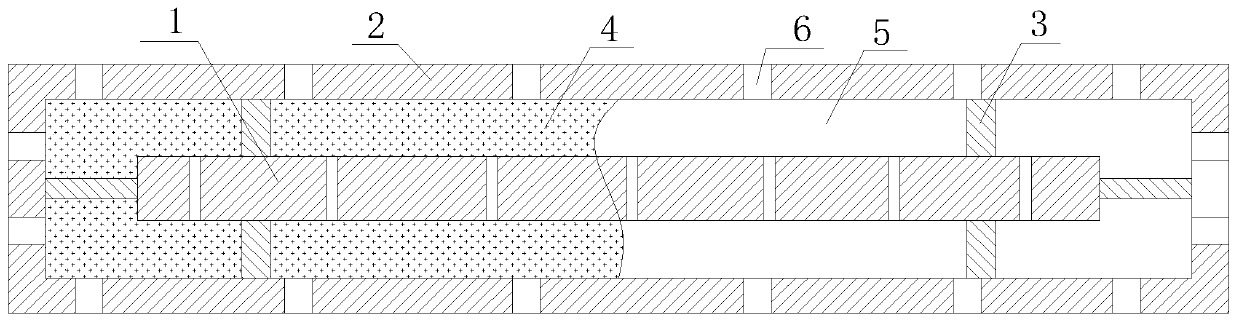

[0034] The first step is the preparation of the alloy matrix. First, the magnesium alloy matrix, the magnesium alloy protective surface, the magnesium alloy connecting plate, and the bearing cavity between the magnesium alloy matrix and the magnesium alloy protective surface are formed by 3D printing to obtain the alloy matrix, and then Soak the alloy matrix in a low-temperature alcohol solution at a temperature of 10°C for later use;

[0035] In the second step, the materials are mixed, and the materials constituting the degraded filling layer are mixed and stirred evenly for later use;

[0036] The third step is material filling. The alloy matrix prepared in the first step is taken out of the alcohol solution and air-dried in a sterile environment, then the alloy matrix is placed in the formin...

Embodiment 2

[0043] Such as figure 2 As shown, a method for preparing a high-strength magnesium alloy-based degradable internal fixation plate for bone trauma, comprising the following steps:

[0044] The first step is the preparation of the alloy matrix. First, the magnesium alloy matrix, the magnesium alloy protective surface, the magnesium alloy connecting plate, and the bearing cavity between the magnesium alloy matrix and the magnesium alloy protective surface are formed by 3D printing to obtain the alloy matrix, and then Soak the alloy matrix in a low-temperature alcohol solution at a temperature of 20°C for later use;

[0045] In the second step, the materials are mixed, and the materials constituting the degraded filling layer are mixed and stirred evenly for later use;

[0046] The third step is material filling. The alloy matrix prepared in the first step is taken out of the alcohol solution and air-dried in a sterile environment, then the alloy matrix is placed in the formin...

Embodiment 3

[0053] Such as figure 2 As shown, a method for preparing a high-strength magnesium alloy-based degradable internal fixation plate for bone trauma, comprising the following steps:

[0054] The first step is the preparation of the alloy matrix. First, the magnesium alloy matrix, the magnesium alloy protective surface, the magnesium alloy connecting plate, and the bearing cavity between the magnesium alloy matrix and the magnesium alloy protective surface are formed by 3D printing to obtain the alloy matrix, and then Soak the alloy matrix in a low-temperature alcohol solution at a temperature of 15°C for later use;

[0055] In the second step, the materials are mixed, and the materials constituting the degraded filling layer are mixed and stirred evenly for later use;

[0056] The third step is material filling. The alloy matrix prepared in the first step is taken out of the alcohol solution and air-dried in a sterile environment, then the alloy matrix is placed in the formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com