Low-energy-consumption sewage treatment system based on energy conservation and environmental protection

A sewage treatment system, energy saving and environmental protection technology, applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of incomplete treatment, polluted water, water pollution, etc., and achieve increased synchronization and stability. , The effect of reducing the setting of the driving parts and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

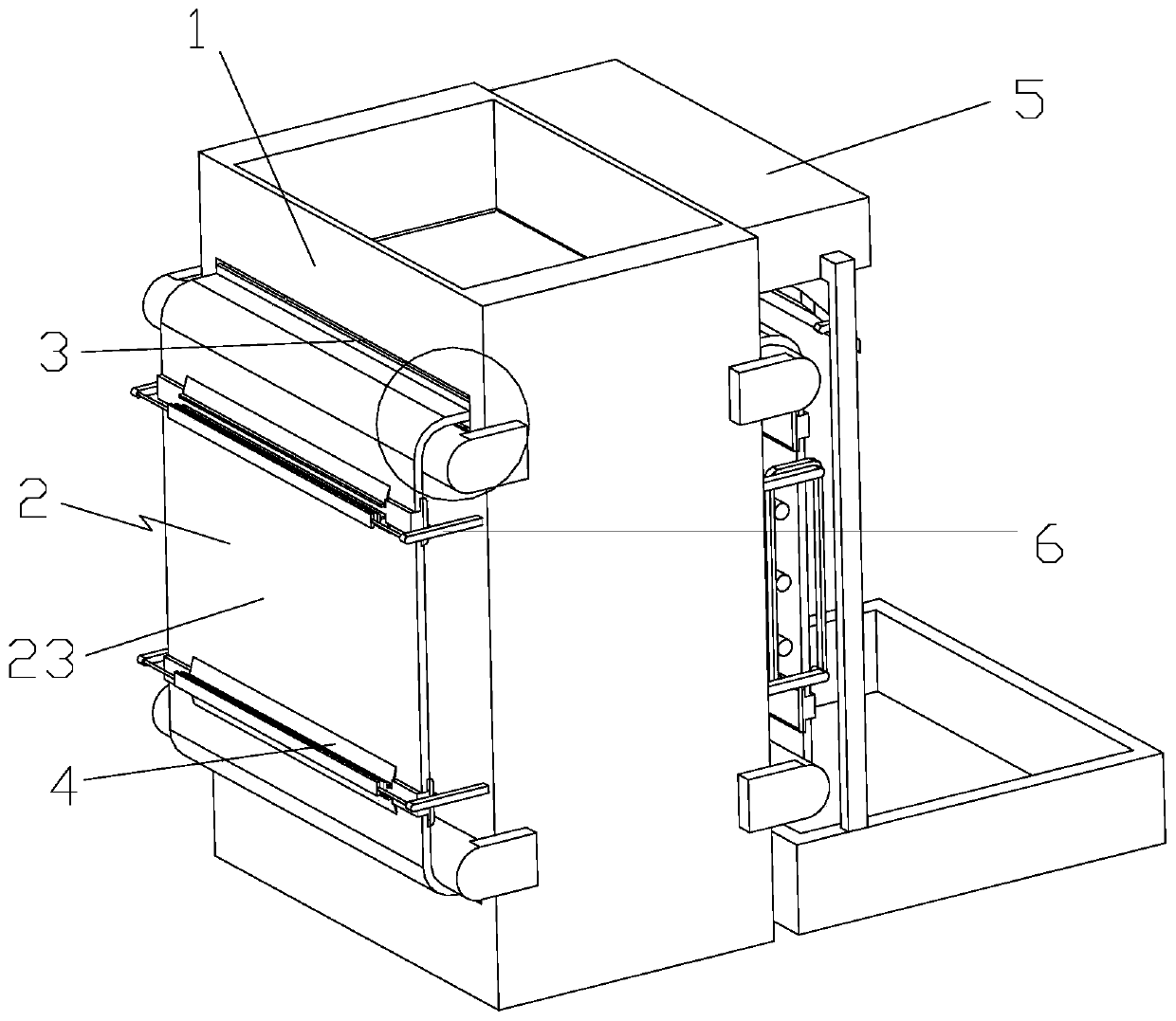

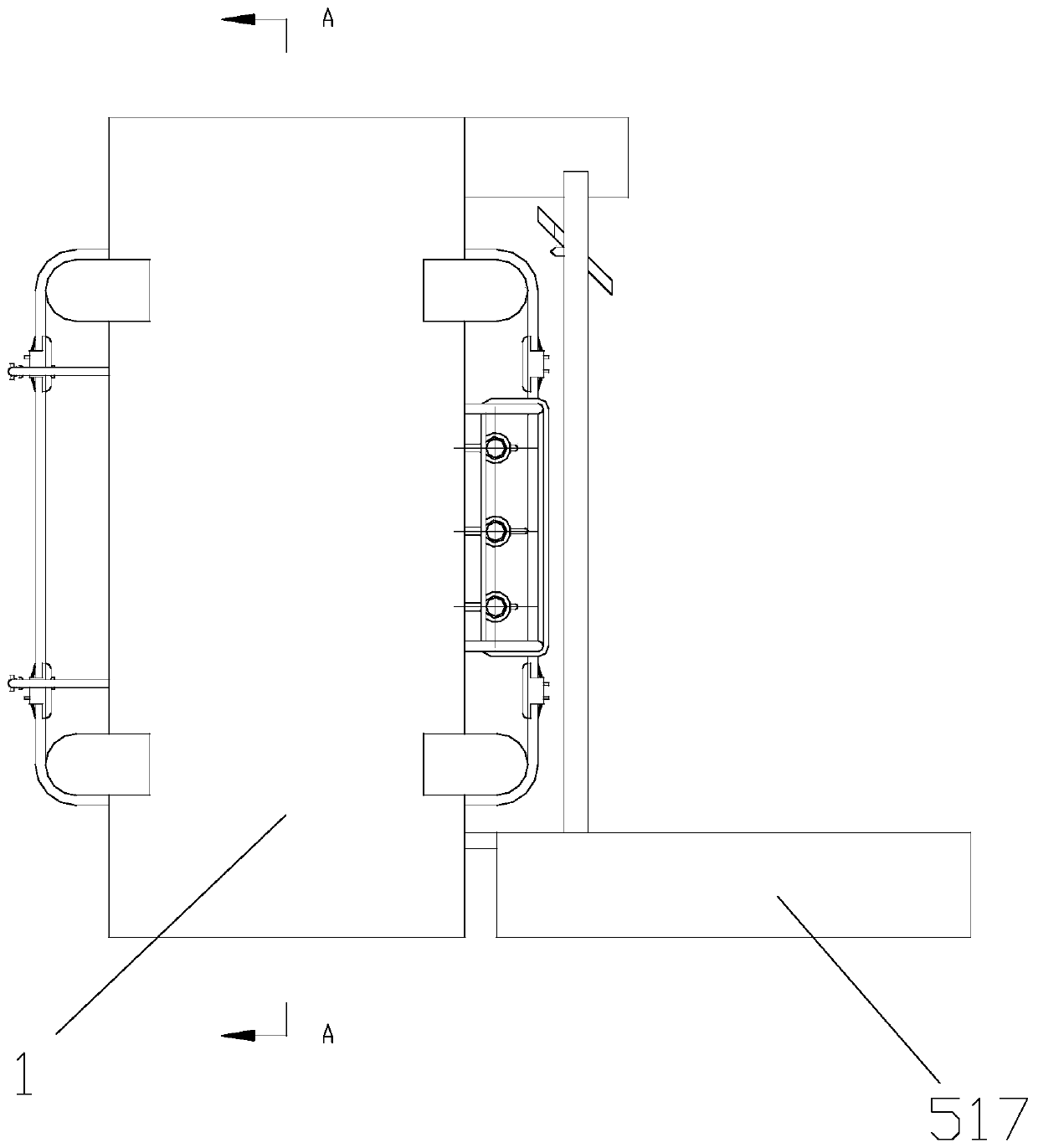

[0036] Such as Figure 1-19 As shown, a low-energy sewage treatment system based on energy saving and environmental protection includes a sewage pipeline 1, a filter device 2 arranged on the sewage pipeline, a plurality of sealing devices 3 arranged on the sewage pipeline and cooperating with the filter device, A plurality of fixing devices 4 on the filtering device, a cleaning device 5 arranged on one side of the sewage pipeline, and a dismantling device 6 arranged on the other side of the sewage pipeline.

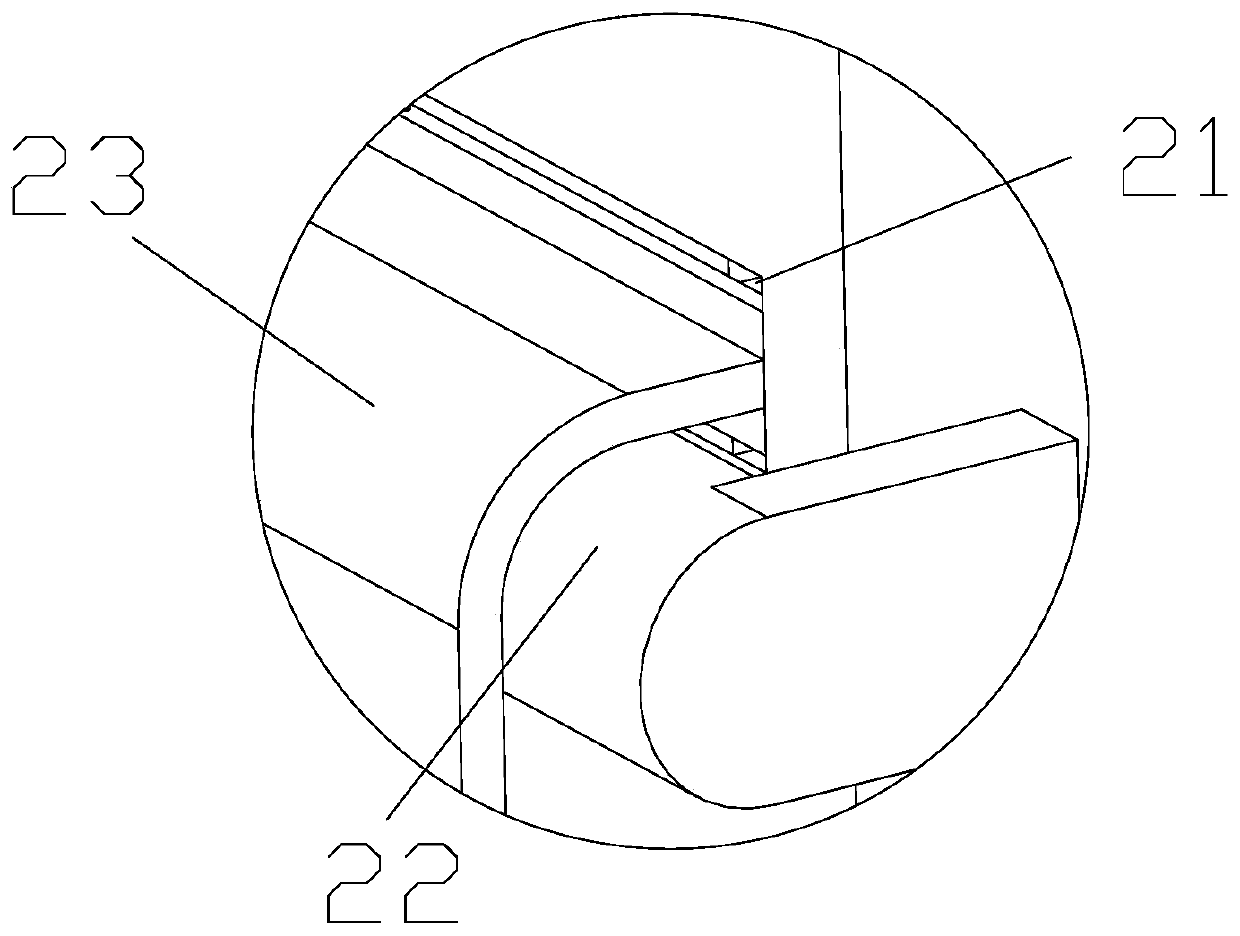

[0037] Described filtering device 2 comprises four openings 21, four rotating shafts 22, a plurality of filter screens 23; Four openings 21 are located on the side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com