A cable quantitative cutting device for construction engineering

A cutting device and construction engineering technology, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of reducing work efficiency, measurement result errors, and high requirements for workers, so as to reduce the demand for human resources and improve the measurement efficiency. Accuracy, the effect of speeding up the progress of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

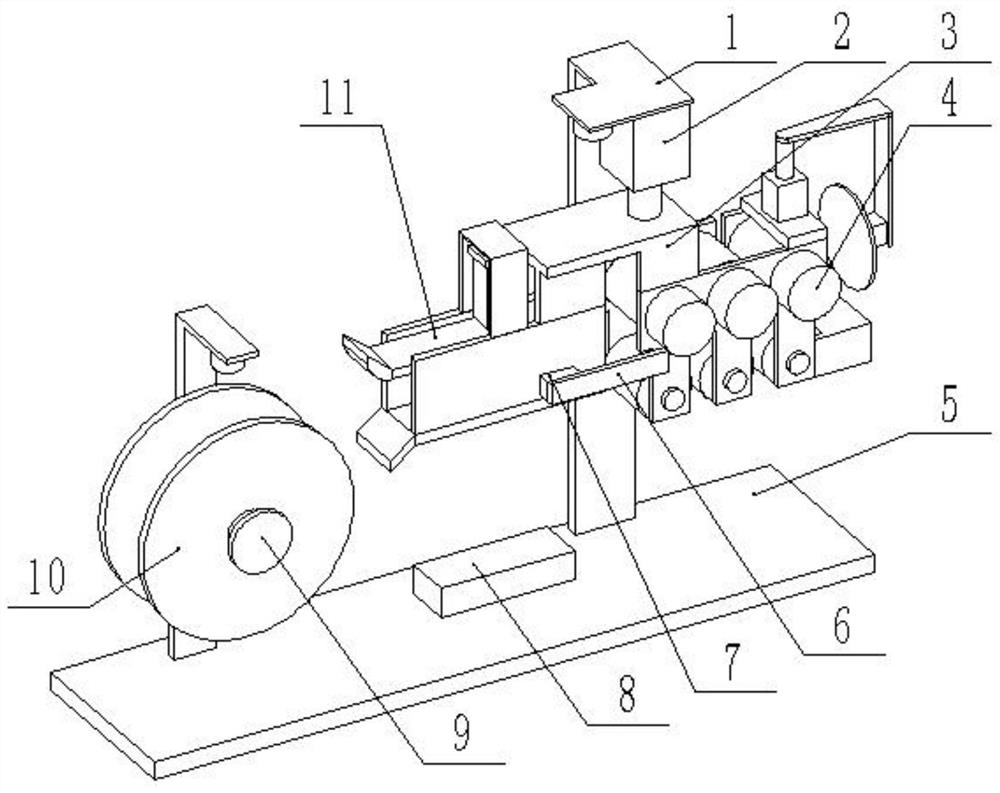

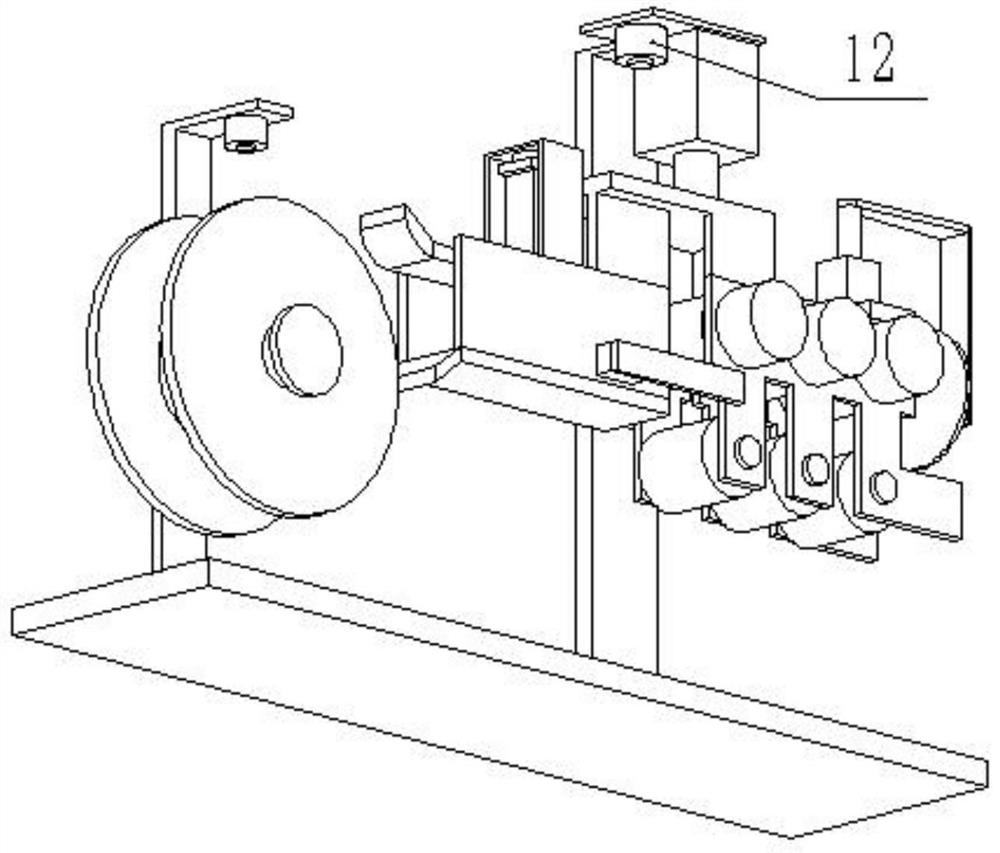

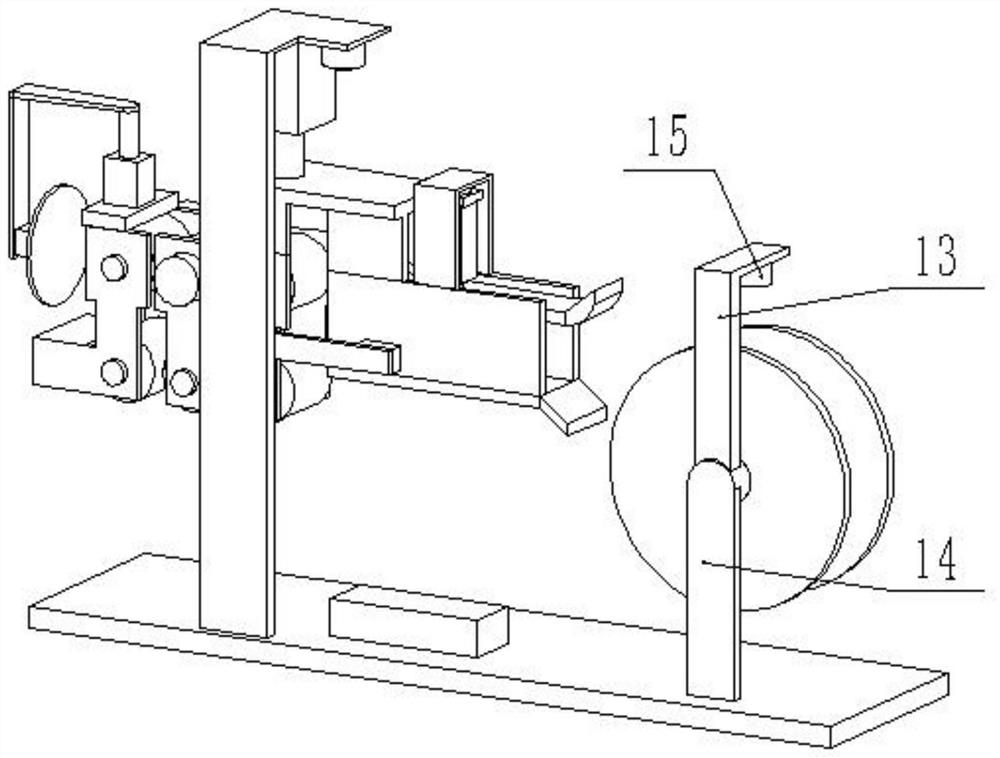

[0019] The present invention is achieved through the following technical solutions: a quantitative cable cutting device for construction engineering, including a first support 1, a first hydraulic cylinder 2, a second support 3, a cutting device 4, a base 5, a third support 6, a first Four brackets 7, a controller 8, a limit bracket 9, a coil 10, a straightening device 11, a first ultrasonic sensor 12, a fifth bracket 13, a sixth bracket 14 and a second ultrasonic sensor 15, the first bracket 1 Installed on the base 5, the first hydraulic cylinder 2 is installed under the first support 1, and it is connected with the second support 3, and the second support 3 is installed on the first hydraulic cylinder 2, which is located on the first Below the hydraulic cylinder 2, the cutting device 4 is installed on the second support 3, which is located in front of the lower side of the second support 3, and the base 5 is installed below the first support 1, which is connected with the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com