A method for synchronous regulation of f/a ratio in double-metal penetrating laser welding multi-layer structure

A bimetal, laser welding technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problem of joint corrosion resistance decline and other problems, and achieve the effect of increasing austenite content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

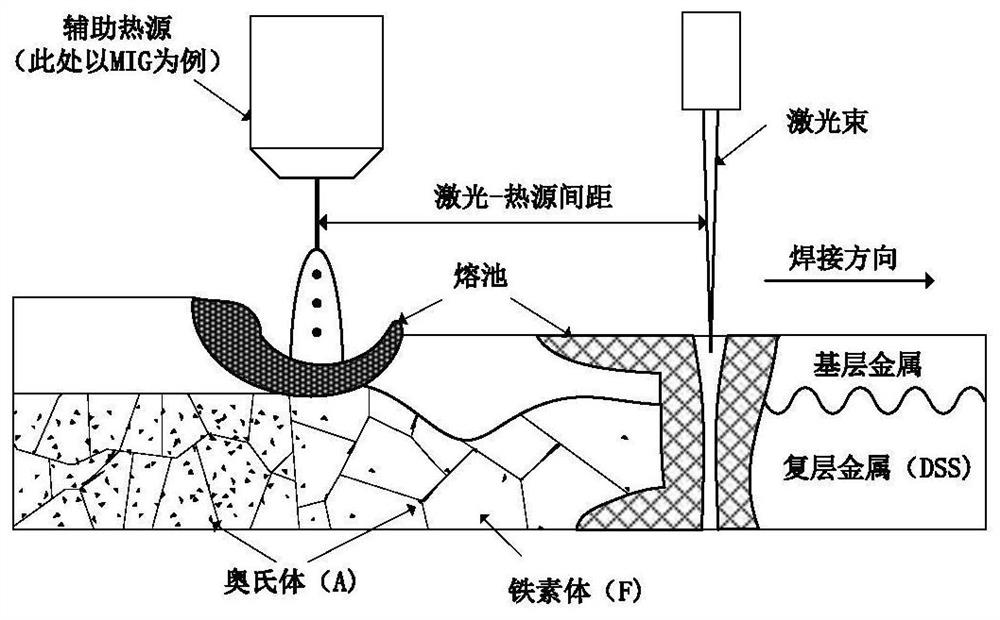

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, a YLS-4000 fiber laser connected in series with a MIG welding torch is used to perform laser welding on a DSS2205 / X65 layered bimetallic composite board. The specific operation steps are as follows:

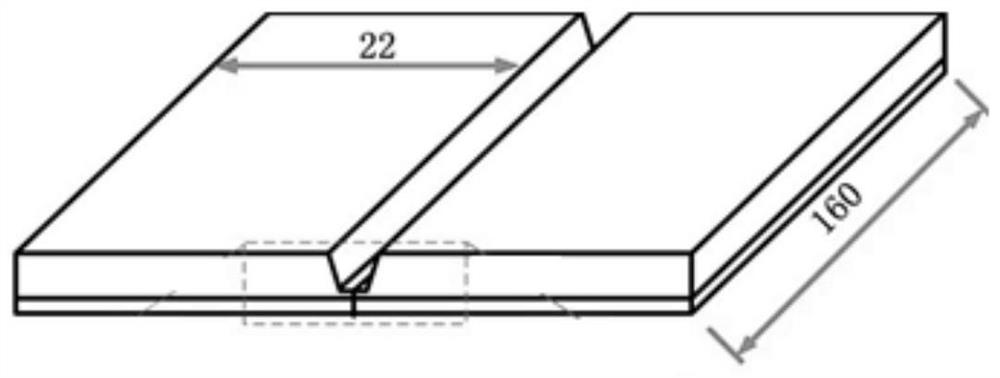

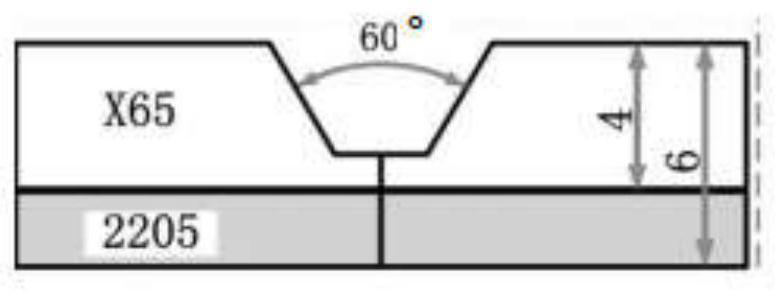

[0036] (1) Process the DSS2205 / X65 layered bimetal composite plate with a thickness of 18 mm as a sample. After processing, the size and shape of the test plate are as follows: Figure 2a and Figure 2b As shown, close to the side of the cladding DSS2205 of the composite board, the thickness of the base material X65 is reserved for 1mm, and the remaining 2mm thick cladding constitutes a total thickness of 3mm "I" type groove, above the "I" type groove, taking into account MIG welding torch space requirements, welding efficiency and weld forming quality and other factors, adopt the form of inverted trapezoidal groove, the width of the bottom of the groove is 3mm, and the opening angle of the groove is 60°;

[0037] (2) Before performing butt welding on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com