Method for preparing sintering-free high-stability mesoporous silica-aluminum material from silica fume and aluminum ash and product

A technology of mesoporous silica and high stability, applied in the direction of chemical instruments and methods, aluminum silicate, silicon compounds, etc., can solve the problems of complex related properties in the preparation process, and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

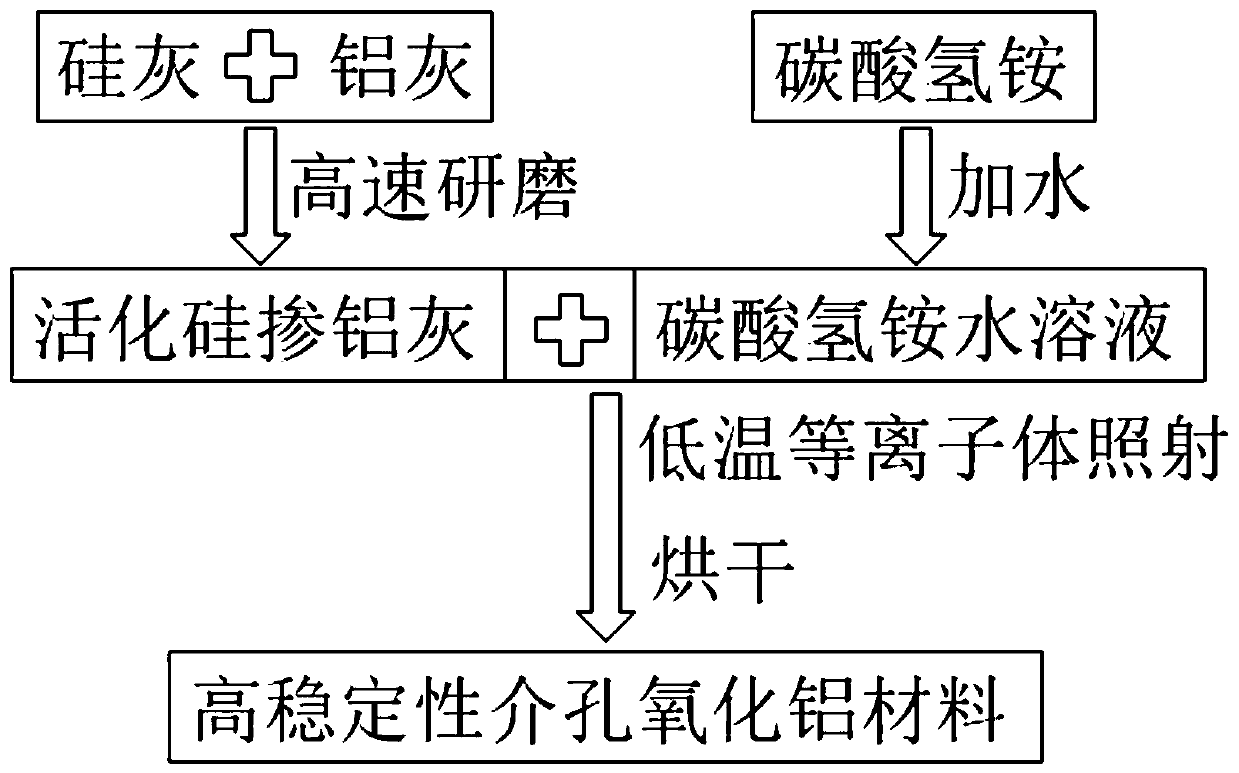

Method used

Image

Examples

Embodiment 1

[0021] Example 1 Influence of the mass ratio of silica fume and aluminum ash on the pore development and stability of the prepared non-sintering mesoporous silica-alumina material

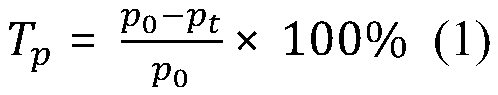

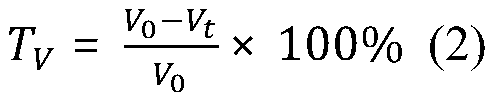

[0022] According to the mass ratio of silica fume and aluminum fume 2.5:100, 3.5:100, 4.5:100, 5:100, 10:100, 15:100, 15.5:100, 16.5:100, 17.5:100, weigh silica fume and aluminum respectively Ash, mixed, and ground at a high speed of 500 rpm for 5 minutes to obtain nine groups of activated silicon-doped aluminum ash. Dissolve ammonium bicarbonate in water to prepare a 2M aqueous solution of ammonium bicarbonate. Weigh the ammonium bicarbonate aqueous solution and the activated silicon-aluminum ash according to the liquid-solid ratio of 1:1mL / mg, mix them, stir at a speed of 30 rpm, and irradiate with low-temperature plasma for 1 hour to obtain nine groups of silicon-aluminum slurries , wherein the action voltage of low-temperature plasma irradiation is 10KV, and the action atmosphere is oxygen. N...

Embodiment 2

[0032] Example 2 Effect of Ammonium Bicarbonate Concentration on Pore Development and Stability of Prepared Sinter-free Mesoporous Alumina Silica Material

[0033]Weigh silica fume and aluminum dust according to the mass ratio of silica fume and aluminum dust of 10:100, mix them, and grind at a high speed of 1500 rpm for 10 minutes to obtain activated silicon-doped aluminum dust. Dissolve ammonium bicarbonate in water, prepare nine groups of ammonium bicarbonate aqueous solutions of 1M, 1.5M, 1.8M, 2M, 4M, 6M, 6.2M, 6.5M, and 7M, and weigh them according to the ratio of liquid to solid: 2:1mL / mg Ammonium bicarbonate aqueous solution and activated silicon-aluminum ash were mixed, stirred at a speed of 90 rpm, and simultaneously irradiated with low-temperature plasma for 1.5 hours to obtain nine groups of silicon-doped aluminum slurries, wherein the applied voltage of low-temperature plasma irradiation was 30KV, The working atmosphere is oxygen. Nine groups of silicon-doped alu...

Embodiment 3

[0038] Example 3 The effect of the applied voltage of low-temperature plasma irradiation on the pore development and stability of the prepared sinter-free mesoporous silica-alumina material

[0039] Weigh silica fume and aluminum dust according to the mass ratio of silica fume and aluminum dust of 15:100, mix them, and grind at a high speed of 2500 rpm for 15 minutes to obtain activated silicon-doped aluminum dust. Dissolve ammonium bicarbonate in water to prepare 6M aqueous ammonium bicarbonate solution. Weigh ammonium bicarbonate aqueous solution and activated silicon-doped aluminum ash according to the liquid-solid ratio of 3:1mL / mg, mix them, stir at a speed of 150rpm, and perform low-temperature plasma irradiation for 2 hours at the same time, wherein the action voltages of low-temperature plasma irradiation are respectively 5KV, 7KV, 9KV, 10KV, 30KV, 50KV, 51KV, 53KV, 55KV, the working atmosphere is oxygen, and nine groups of silicon-doped aluminum pastes are obtained. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com