High-efficiency polymerization inhibitor for extracting and separating C5 by DMF method and application method thereof

An application method and technology of a polymerization inhibitor, applied in chemical instruments and methods, distillation purification/separation, hydrocarbon purification/separation, etc., can solve problems such as difficulty, large odor of waste liquid and solid waste, and large workload of disassembly and assembly. , to achieve the effect of reducing solid waste generation, tar production, and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with a polymerization inhibitor, but it does not constitute a limitation of the present invention.

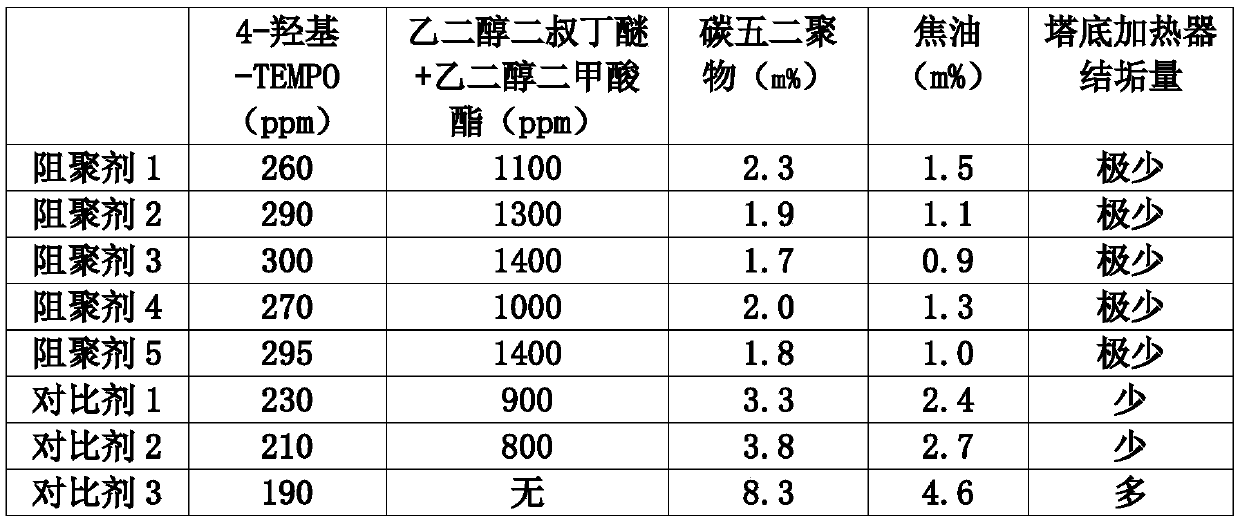

[0028]In the C5 extraction and rectification evaluation test device, the application effects of each polymerization inhibitor and contrast agent listed in Table 1 are evaluated successively, and the first extraction of the C5 industrial device is extracted and separated by an extractive distillation column simulating DMF method. The operating conditions of the rectification tower, and with the carbon five fraction feed (removed dicyclopentadiene and heavy components, isoprene mass content 27-30% from the first extractive rectification tower, O 2 Content is lower than 100ppm, and moisture content is lower than 200ppm) as test raw material, and the bottom discharge of extraction rectification column is separated DMF extraction solvent through a rectification column again, and DMF extraction solvent is recy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com