Method for preparing polycarboxylate water reducer by adopting C6 monomer

A technology of polycarboxylic acid and water-reducing agent, which is applied in the field of concrete admixture, can solve the problems of easy retardation, low water-reducing rate, and large air content, and achieve the effects of mild reaction conditions, improved water-reducing performance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

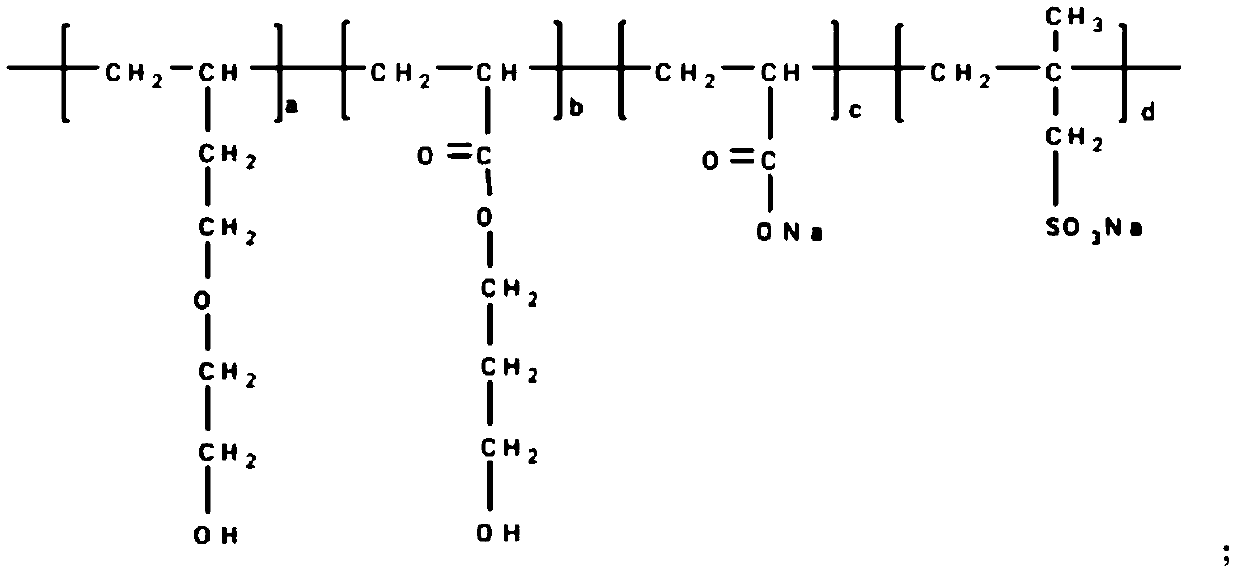

Method used

Image

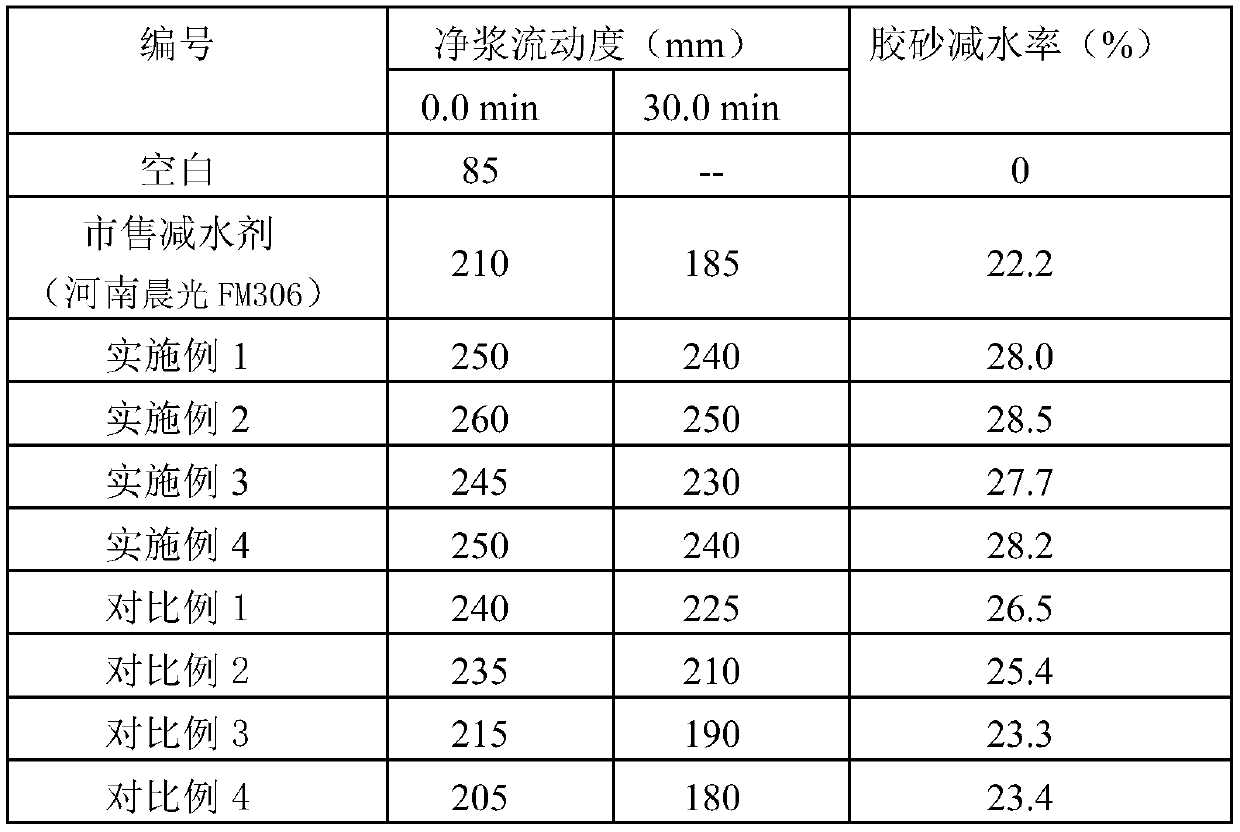

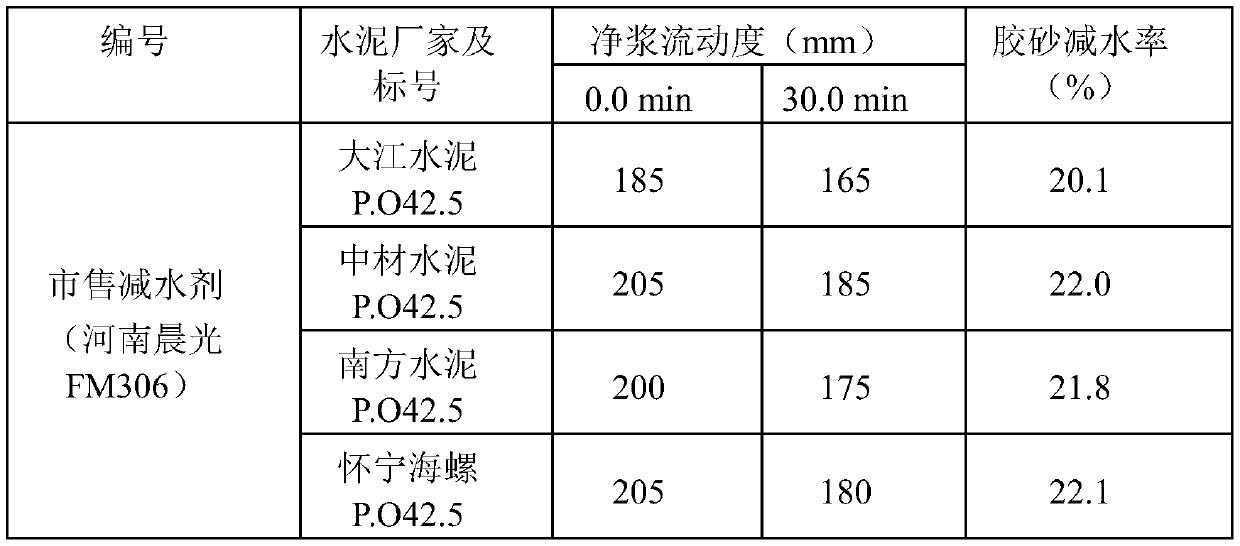

Examples

Embodiment 1

[0046] Adopt the method for preparing polycarboxylate water-reducer by C6 monomer, comprise the following steps:

[0047](1) Add 200.0kg of deionized water and 150.0kg of hydroxyethyl-3-butenyl ether into the reactor, and stir at room temperature;

[0048] (2) Preparation of material A: Add 120.0kg of deionized water, 27.0kg of acrylic acid, 15.0kg of sodium methacrylate, and 1.2kg of 2-mercaptoacetic acid into the reactor, mix and stir to prepare material A;

[0049] (3) Preparation of material B: add 120.0kg deionized water and 0.6kg reducing agent into the reactor, mix and stir, and prepare material B; wherein 0.6kg reducing agent is 0.4kg sodium ascorbate and 0.2kg sodium ascorbate (hyposulfuric acid sodium hydrogen formaldehyde);

[0050] (4) Add A material, B material, 150.0kg hydroxypropyl acrylate and 2.4kg hydrogen peroxide dropwise to the reaction kettle of step (1) at the same time, control the rate of addition so that the reaction temperature should not exceed 40°...

Embodiment 2

[0053] The difference between this example and Example 1 is that the hydroxyethyl 3-butenyl ether in the step (1) of Example 1 is replaced with hydroxypropyl allyl ether, and other conditions are the same.

Embodiment 3

[0055] The difference between this example and Example 1 is that: 200.0 kg of hydroxyethyl-3-butenyl ether, 100.0 kg of hydroxypropyl acrylate, and other conditions are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com