Water-based ink for printing PVC decorative material and preparation method thereof

A decorative material, water-based technology, applied in the field of water-based ink for printing PVC decorative materials and its preparation, can solve the problems of poor stability, slow drying of water-based ink, low adhesion fastness, etc., and achieves good stability, fast drying speed, The effect of improving adhesion fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

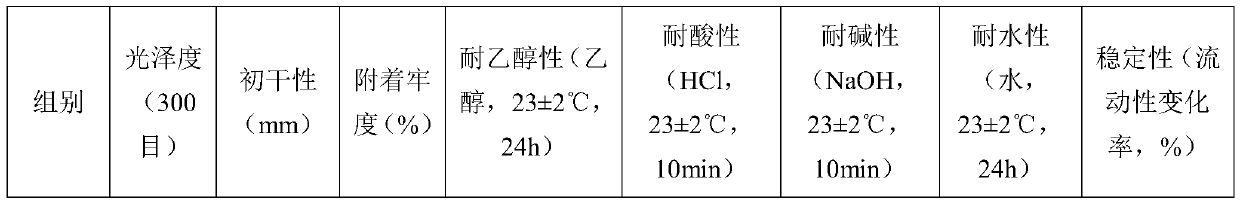

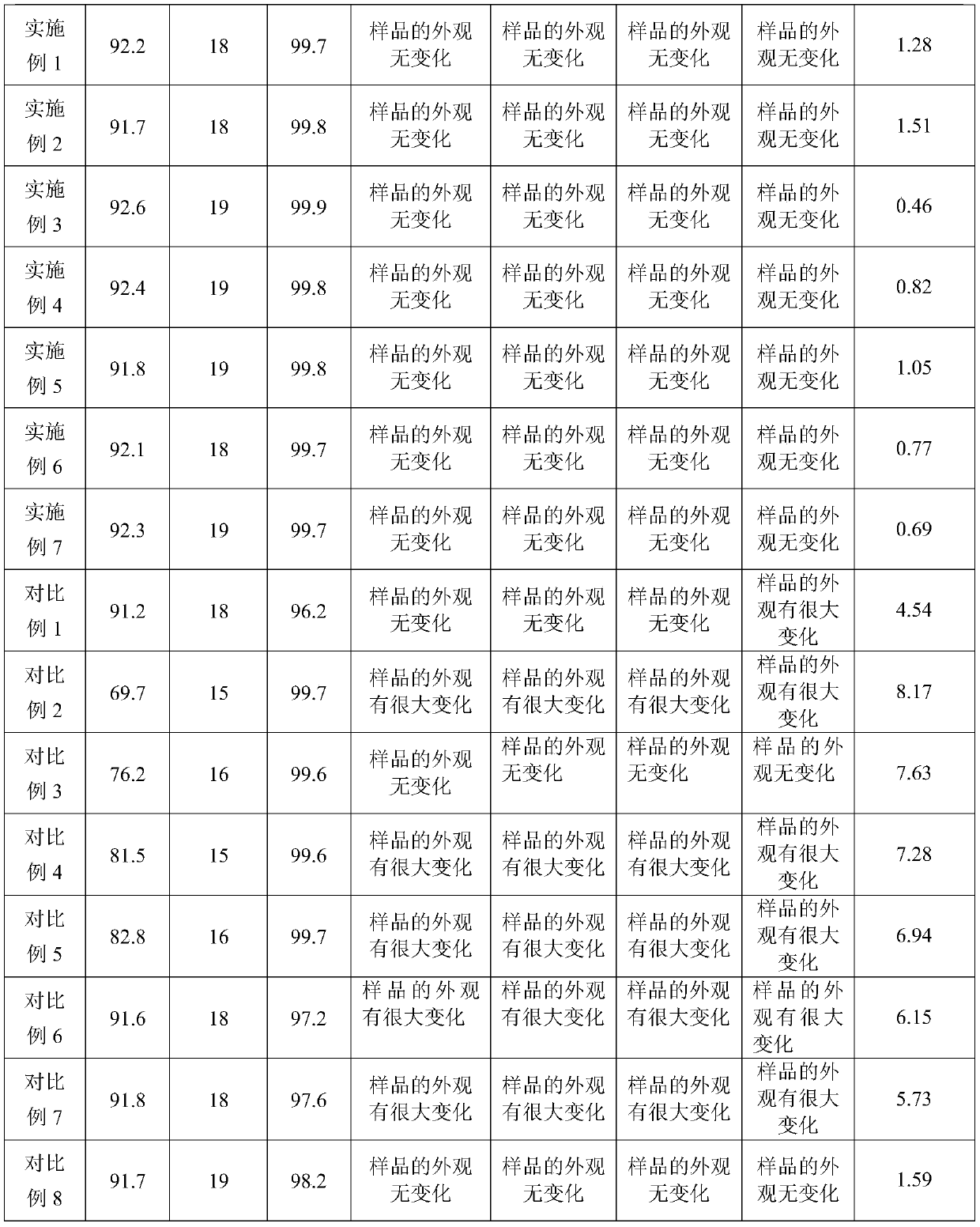

Examples

Embodiment 1

[0033] A water-based ink for PVC decoration material printing, comprising the following components by weight:

[0034] 45 parts of water-based color paste, 15 parts of water-based acrylic emulsion, 20 parts of water-based acrylic modified polyurethane emulsion, 1 part of water-based wax paste, 3 parts of pH stabilizer, 0.9 parts of defoamer, 0.5 parts of leveling agent, and 1 part of drier Parts, 2 parts of deionized water,

[0035] Among them, the water-based color paste is composed of the following components by weight: 15 parts of water-based acrylic resin liquid, 34 parts of organic pigment, 3 parts of wetting and dispersing agent, 1.2 parts of silicone defoamer, 43 parts of deionized water; drier It is a mixture of nanometer yttrium oxide, butadienyl triethoxysilane, polylactic acid-glycolic acid copolymer and deionized water in a mass ratio of 1:0.2:3:7; the preparation method of the drier is as follows: Add polylactic acid-glycolic acid copolymer into deionized water, ...

Embodiment 2

[0041] A water-based ink for PVC decoration material printing, comprising the following components by weight:

[0042]50 parts of water-based color paste, 20 parts of water-based acrylate emulsion, 25 parts of water-based acrylic modified polyurethane emulsion, 2 parts of water-based wax paste, 5 parts of pH stabilizer, 1.5 parts of defoamer, 1 part of leveling agent, 2 parts of drier parts, 5 parts of deionized water,

[0043] Among them, the water-based color paste is composed of the following components by weight: 15 parts of water-based acrylic resin liquid, 34 parts of organic pigment, 3 parts of wetting and dispersing agent, 1.2 parts of silicone defoamer, 43 parts of deionized water; drier It is a mixture of nanometer yttrium oxide, butadienyl triethoxysilane, polylactic acid-glycolic acid copolymer and deionized water in a mass ratio of 1:0.2:3:7; the preparation method of the drier is as follows: Add polylactic acid-glycolic acid copolymer into deionized water, add n...

Embodiment 3

[0046] A water-based ink for PVC decoration material printing, comprising the following components by weight:

[0047] 47 parts of water-based color paste, 18 parts of water-based acrylate emulsion, 23 parts of water-based polyurethane emulsion, 1.5 parts of water-based wax paste, 4 parts of pH stabilizer, 1.2 parts of defoamer, 0.7 parts of leveling agent, 1.5 parts of drier, to 3.2 parts of ionized water,

[0048] Among them, the water-based color paste is composed of the following components by weight: 15 parts of water-based acrylic resin liquid, 34 parts of organic pigment, 3 parts of wetting and dispersing agent, 1.2 parts of silicone defoamer, 43 parts of deionized water; drier It is a mixture of nanometer yttrium oxide, butadienyl triethoxysilane, polylactic acid-glycolic acid copolymer and deionized water in a mass ratio of 1:0.2:3:7; the preparation method of the drier is as follows: Add polylactic acid-glycolic acid copolymer into deionized water, add nanometer ytt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com