Polishing solution for chemico-mechanical polishing of silicon carbide

A chemical mechanical and polishing fluid technology, applied to polishing compositions containing abrasives, etc., can solve problems such as increasing equipment corrosion, affecting surface roughness, and increasing silicon carbide surface corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

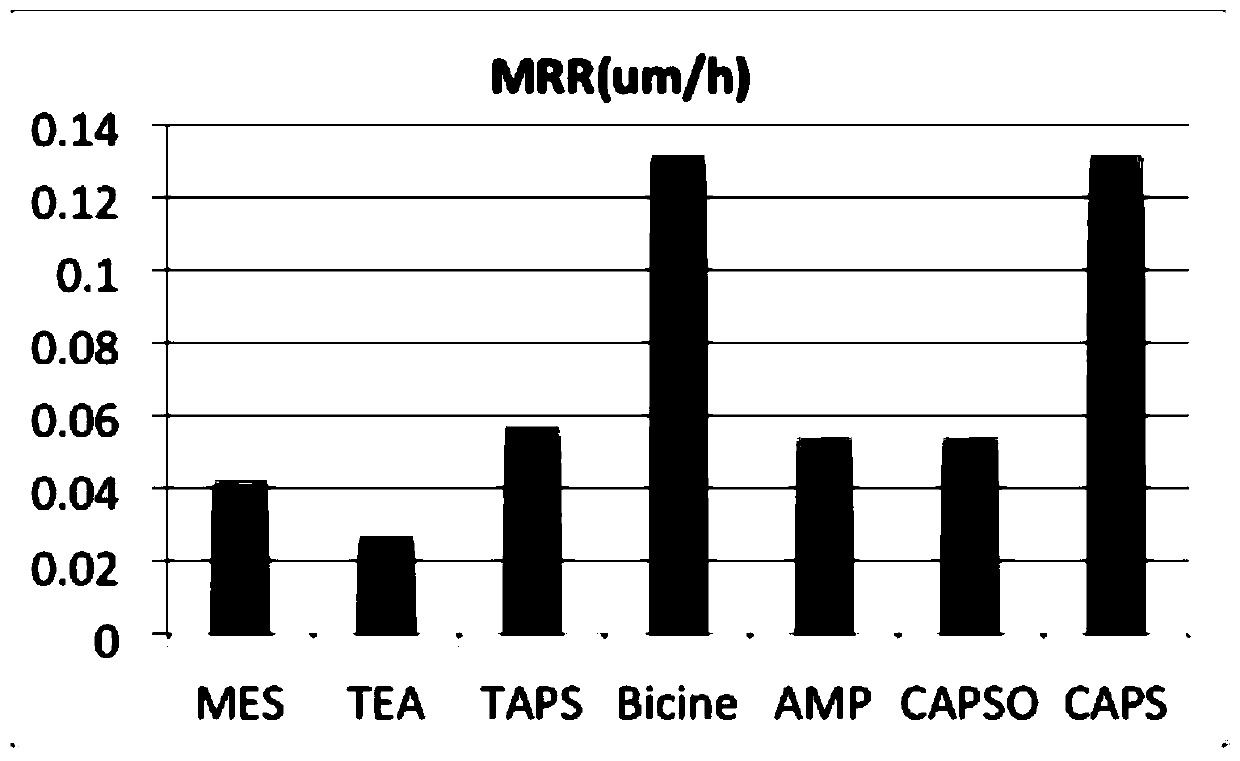

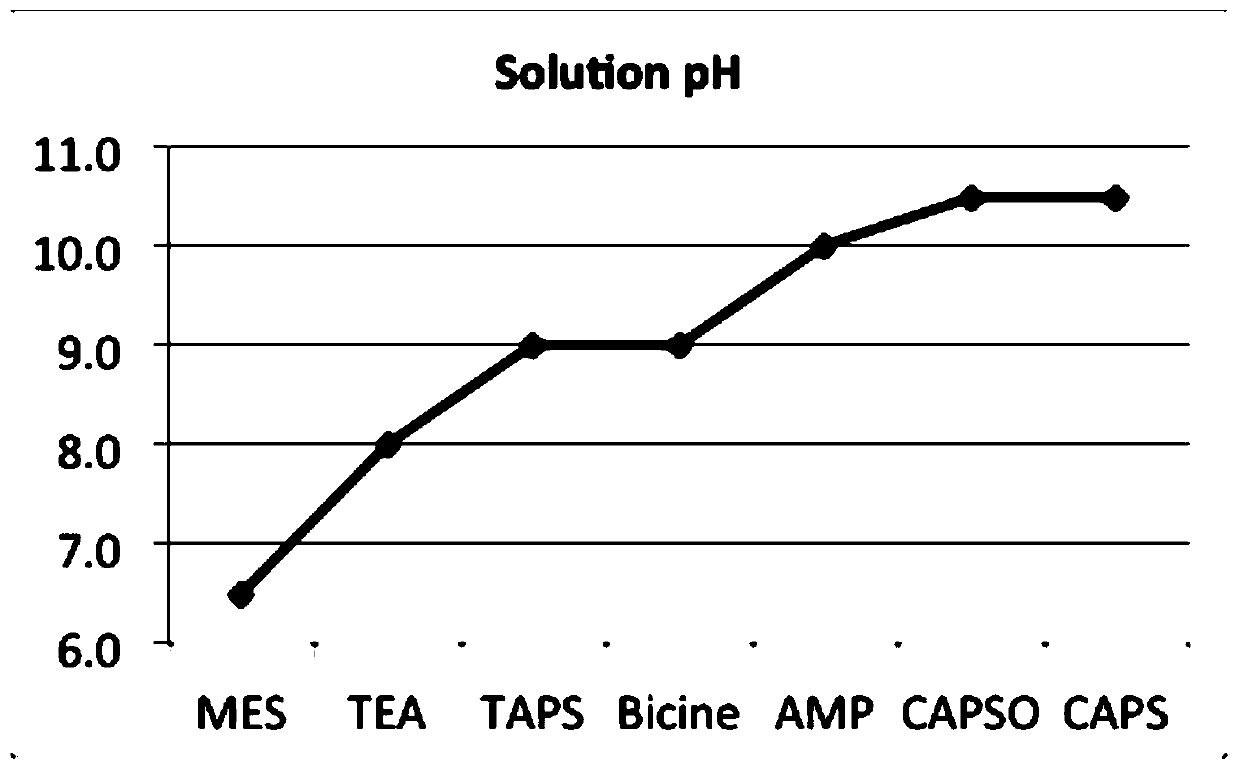

[0032] In this example, seven biological buffers were selected. They have different pKa, covering the pH range of 6-11. These biological buffers are: MES (pKa=6.1), TEA (pKa=7.8), TAPS (pKa=8.4), Bicine (pKa=8.3), AMP (pKa=9.7), CAPSO (pKa=9.6) , and CAPS (pKa=10.4). Polishing solutions containing these biological buffers were prepared under the same conditions. The SiO that present embodiment selects for use Abrasive is particle diameter 100 nanometers, concentration 5%, in described solution, add the different damping solution of 0.25% (percentage by weight), finally add 3%H 2 o 2 , and then adjust the pH of the solution. Wherein, the pH values of the solutions are: MES: 6.5; TEA: 8.0; TAPS: 9.0; Bicine: 9.1; AMP: 10.0; CAPSO: 10.0; The polishing conditions are as follows: the rotational speed of the polishing disc: 60 RPM, the liquid feeding speed: 30 ml / min, and the pressure 8.5 psi.

[0033] Polishing results are shown in figure 1 and figure 2 . Depend on fig...

Embodiment 2

[0035] In this embodiment, the two best-performing biological buffers Bicine and CAPS were selected for further testing. The SiO used in this embodiment 2 Abrasives are particle diameter 120 nanometers, weight percent concentration 10%, add respectively the Bicine and CAPS of 0.5% (weight percent) in described solution, finally add 6%H 2 o 2 , and then adjust the pH value of the solution to 9.1 (Bicine) and 10.5 (CAPS) respectively. The polishing conditions are as follows: the rotational speed of the polishing disc: 60 RPM, the liquid feeding speed: 30 ml / min, and the pressure 8.5 psi.

[0036] The conditions of this example produced very different results from Example One. The removal rate of the polishing solution added with Bicine was significantly reduced to MRR=0.077μm / h, while the polishing solution containing CAPS produced a high removal rate of MRR=0.237μm / h. The average roughness Ra of the polished silicon carbide surface is between 0.2-0.3nm as measured by an ato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com