Anti-ultraviolet and wear-resistant fabric and silk stockings

An anti-ultraviolet and fabric technology, applied in the field of clothing and home textiles, can solve the problems of poor durability and protection function, weak anti-ultraviolet ability, and general mechanical strength of stockings, so as to achieve ultraviolet radiation resistance, a good sense of freedom, and improve ultraviolet resistance. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

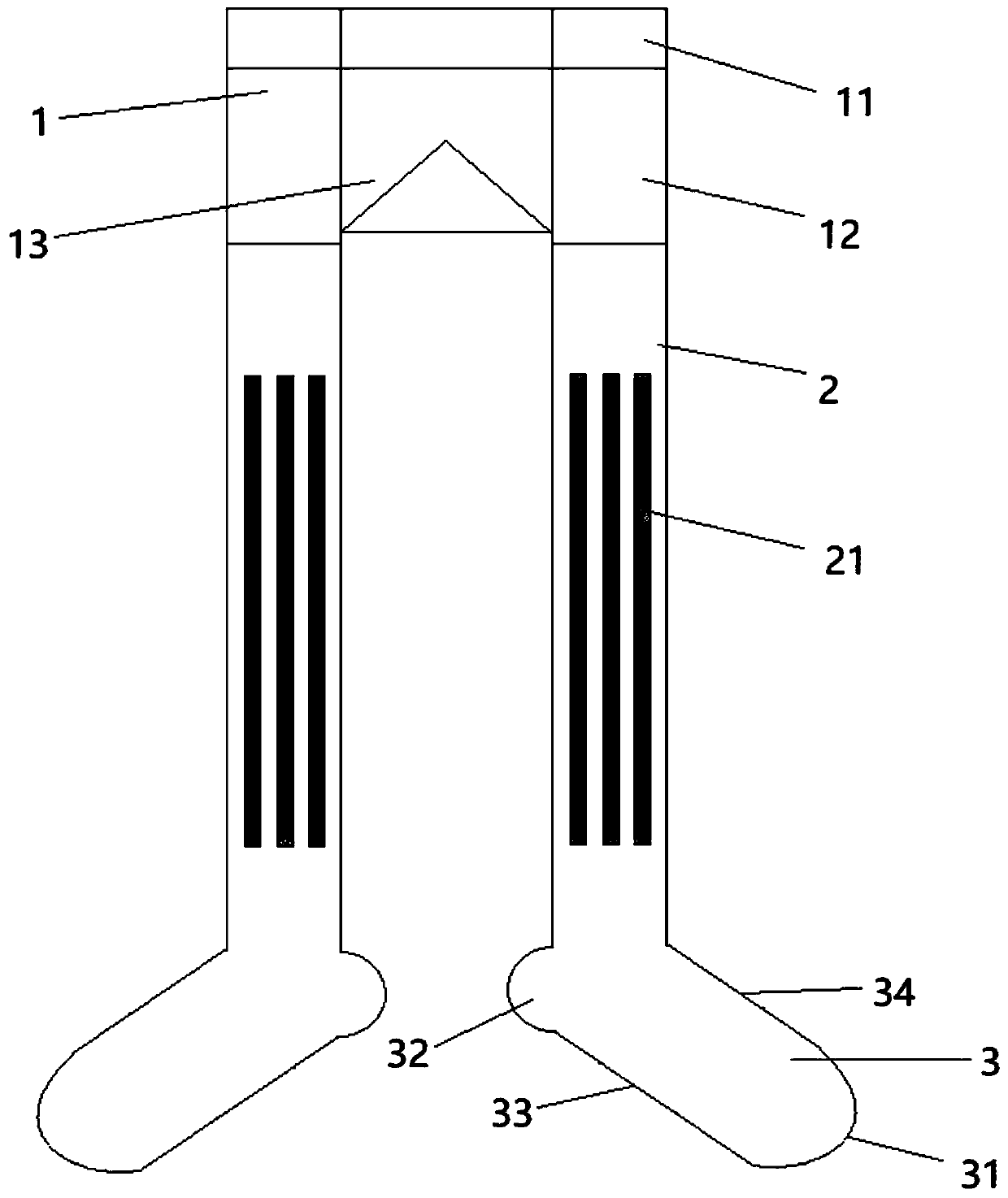

[0049] Example 1 panty stockings

[0050] Such as figure 1 As shown, the panty stockings provided by the embodiment of the present application include pantyhose 1, stocking tube 2 and sock foot 3, and pantyhose 1 comprises trousers waist 11 and trousers body 12, and the middle part of trousers body 12 is the crotch portion 13 with certain width , the cross section of the sock tube 2 is circular, and the two sock tubes 2 are connected by the socks 1 . The stocking 2 and the sock foot 3 are made of a plain stitch knitted with ultra-high molecular weight polyethylene yarn, spandex and anti-ultraviolet yarn. The plain stitch of the sock 2 and the sock foot 3 both contain spandex. Can effectively improve the elasticity of stockings. The sock tube 2 part also includes a jacquard weave 21 with stripes. The stripes in the jacquard weave 21 are in the shape of vertical stripes. The sock foot 3 includes a sock toe 31, a sock heel 32, a sock bottom 33 and a sock top 34. Both the sock ...

Embodiment 2

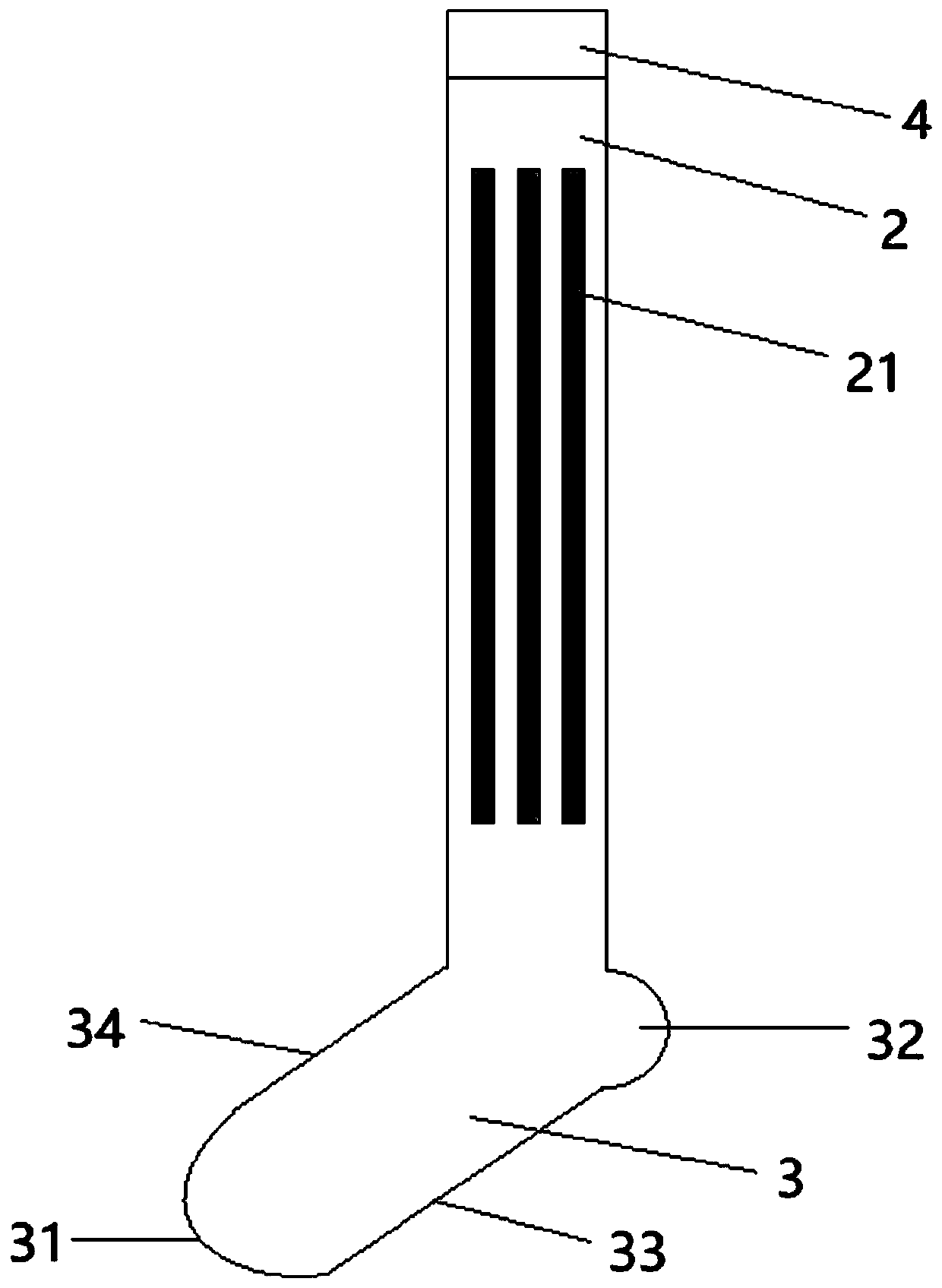

[0051] Embodiment 2 stockings

[0052] Such as figure 2 As shown, the panty stockings provided by the embodiment of the present application include a sock tube 2 and a sock foot 3, the upper end of the sock tube 2 is a cuff 4, the cross section of the sock tube 2 is a complete circle, and the two sock tubes 2 exist independently . The stocking 2 and the sock foot 3 are made of ultra-high molecular weight polyethylene yarn, anti-ultraviolet yarn and spandex as raw materials, and the plain stitches of the sock 2 and the sock foot 3 both contain spandex, which can Effectively improve the elasticity of stockings. The sock tube 2 also includes a striped jacquard weave 21, the stripes in the jacquard weave 21 are in the shape of vertical stripes, and the sock tube 2 of each stocking has six vertical stripes, which are equidistantly distributed on the circumferential surface of the sock tube 2. The sock foot 3 includes a sock toe 31, a sock heel 32, a sock bottom 33 and a sock to...

Embodiment 3

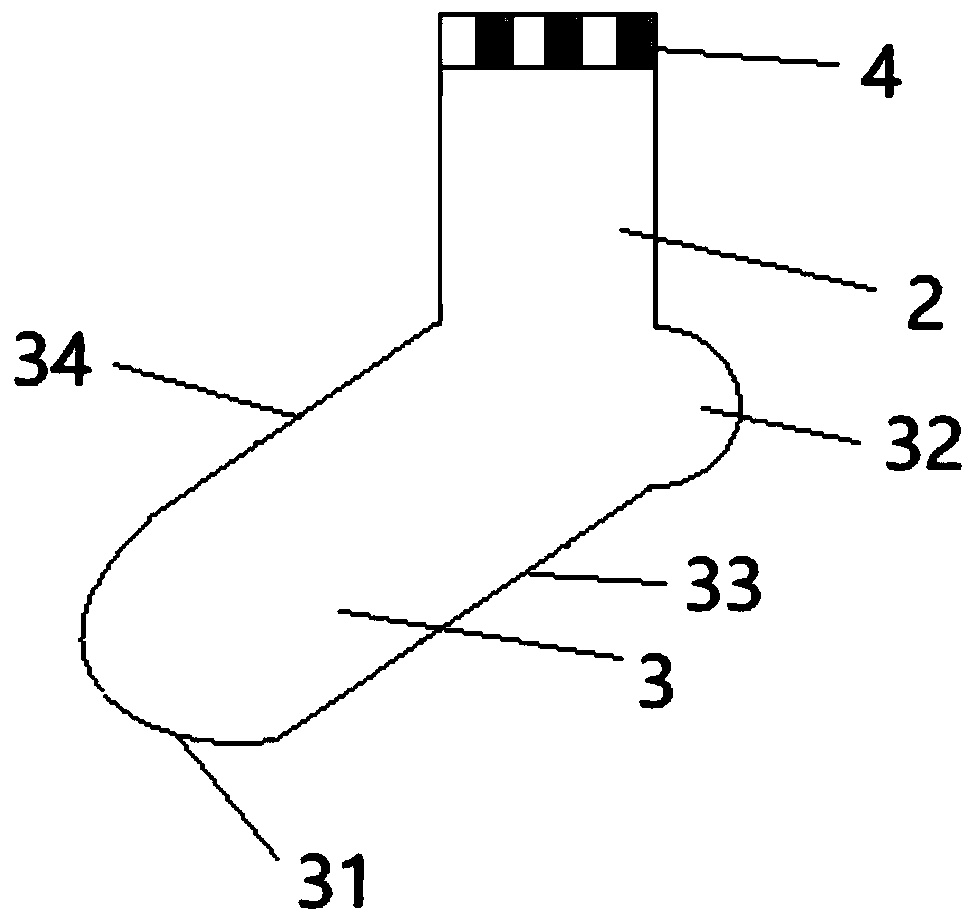

[0053] Embodiment 3 short tube stockings

[0054] Such as image 3 As shown, the stockings provided by the embodiment of the present application include a sock tube 2 and a sock foot 3, the upper end of the sock tube 2 is a cuff 4, the cross section of the sock tube 2 is a complete circle, and the two sock tubes 2 exist independently . Cuff 4 is made of color stripe rib weave made of ultra-high molecular weight polyethylene yarn, anti-ultraviolet yarn and spandex. Sock tube 2 and sock foot 3 are made of ultra-high molecular weight polyethylene yarn, anti-ultraviolet yarn The plain stitch knitted with spandex as raw material, the plain stitch of the sock tube 2 and the sock foot 3 all contain spandex, which can effectively improve the elasticity of the stockings. The sock foot 3 includes a sock toe 31, a sock heel 32, a sock bottom 33 and a sock top 34. Both the sock bottom 33 and the sock heel 32 have bamboo fiber reinforcement lines. pouch-shaped structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com