Radial drive telescopic arm non-forming cutting digging drilling tool

A telescopic arm and drilling tool technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problems of large resistance of excavation and reaming drilling tools, inability to excavate complex hole patterns, and failure to achieve the diameter expansion ratio. To achieve the effect of reasonable force, light weight and good cutting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

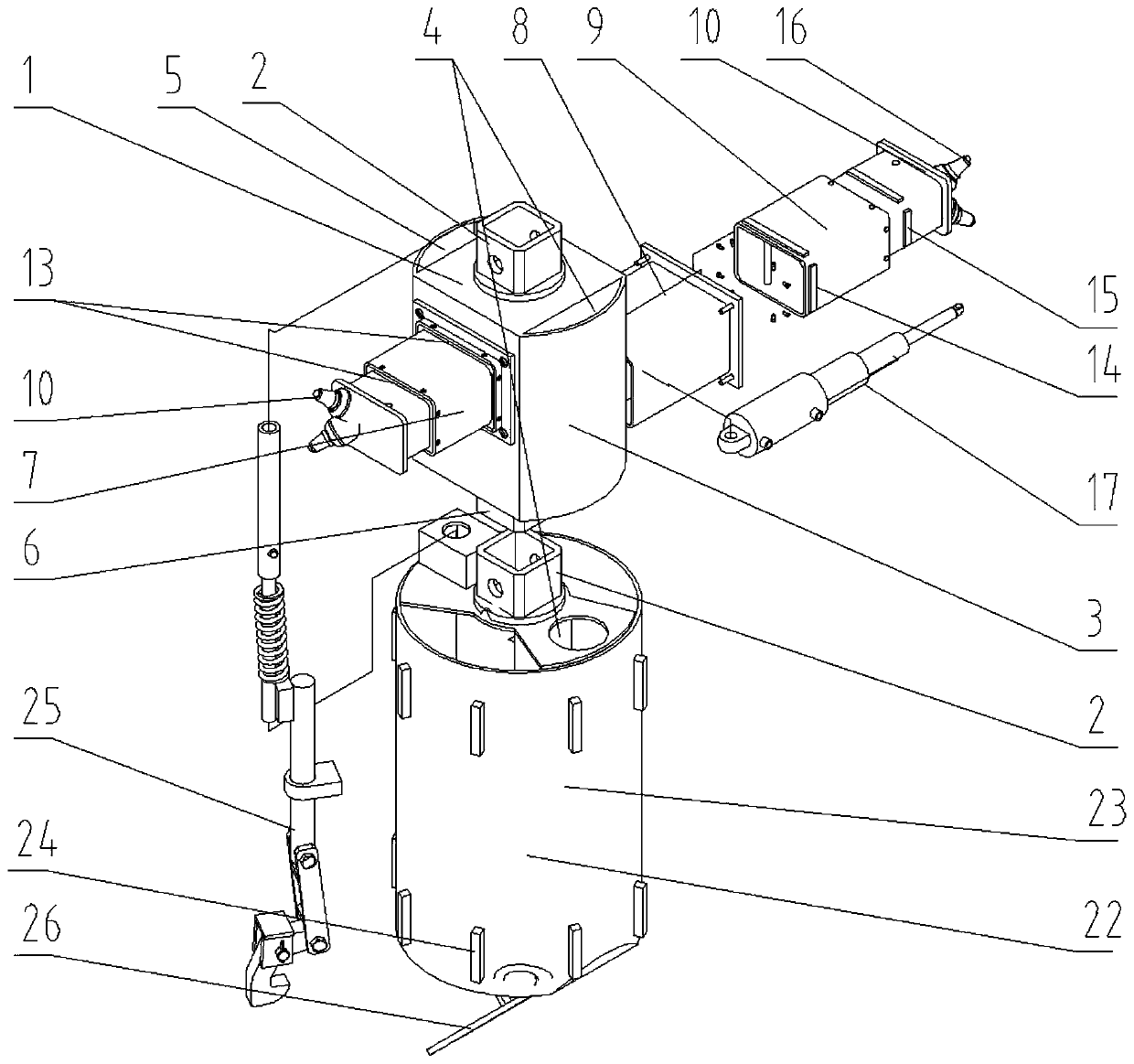

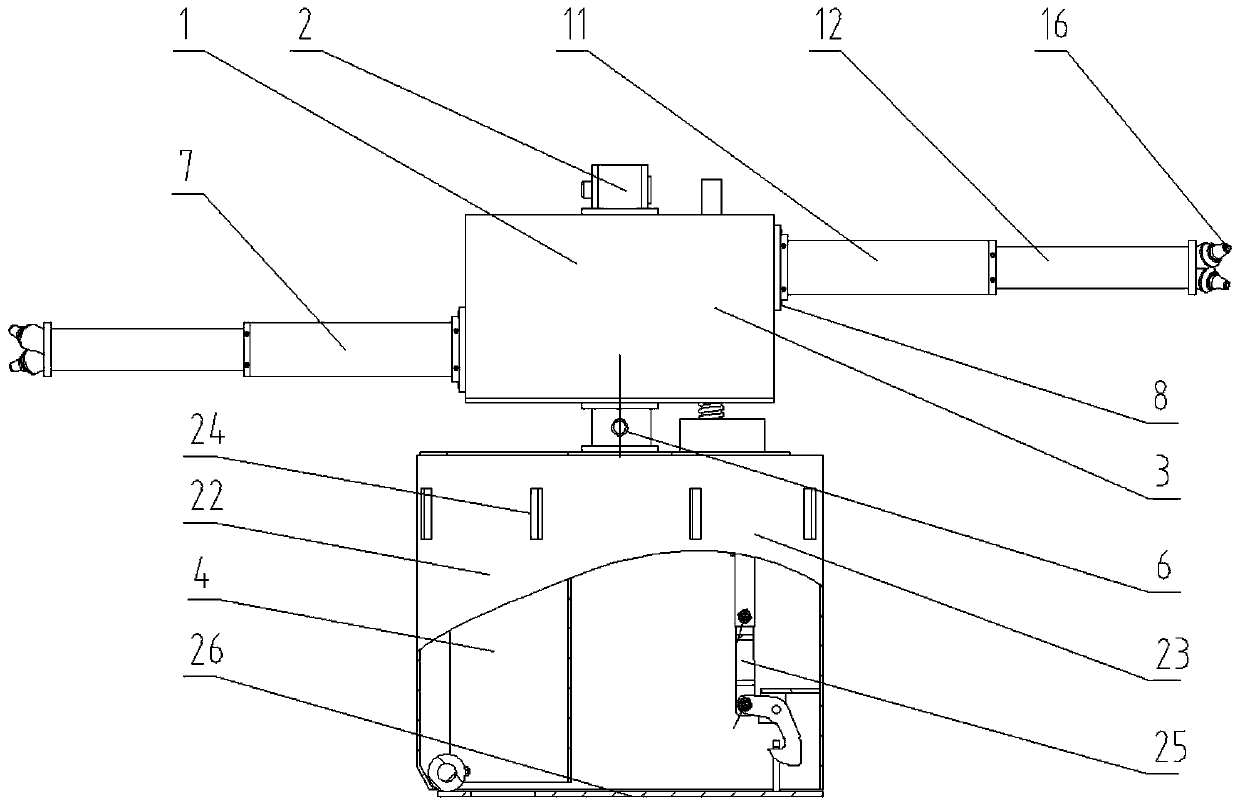

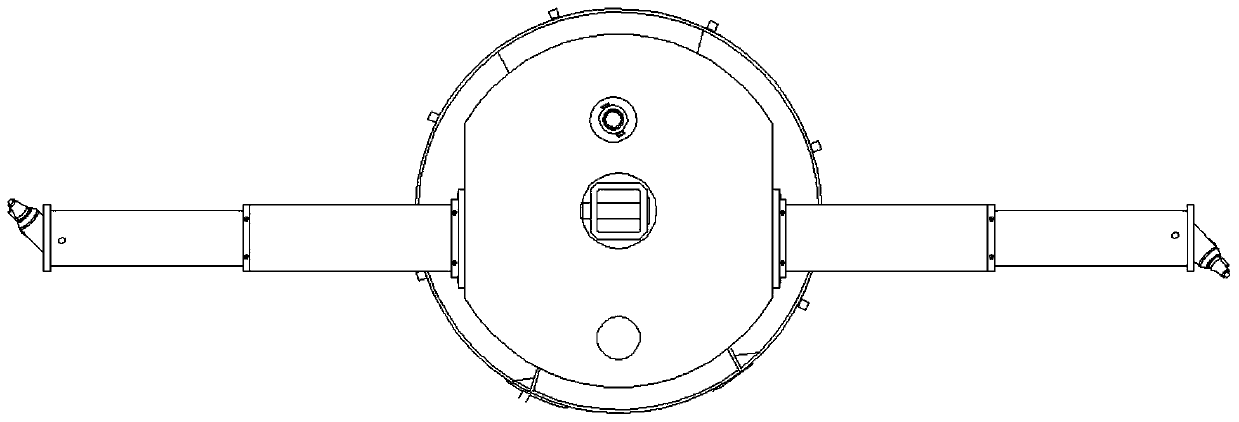

[0037]The radially driven telescopic arm non-shaped cutting and digging drilling tool includes a single-stage cutting unit 27 , a mounting seat 1 , and a slag receiving bucket 22 . The single-stage cutting unit 27 includes a fixed arm 8, a telescopic arm 9, a front-end support slide 13, a tail-end support slide 14, a limit block 15, a cutting tool 16, a single-stage double-acting actuator 18, and a magnetostrictive displacement sensor 30; the fixed arm 8 is installed in the radial hole of the mounting seat 1, the piston rod end and the bottom end of the cylinder of the single-stage double-acting actuator 18 are respectively connected with the telescopic arm 9 and the fixed arm 8, and the front end of the front end of the fixed arm 8 is installed on the inner side The support slider 13, the tail end support slider 14 is installed on the outer side of the rear end of the telescopic arm 9, the cutting tool 16 is installed on the front end face of the telescopic arm 9, the front en...

Embodiment 2

[0045] The cutting unit 7 can also be a two-stage cutting unit 28, which can overcome the deduction of the structure size due to the ineffective stroke of the actuator 17, and the radially driven telescopic arm of the single-stage cutting unit 27 can not achieve 3 times of the unshaped cutting and digging tools. Specifications for the expansion ratio. The telescopic arm 9 of the two-stage cutting unit 28 is divided into two stages, namely the first-stage telescopic arm 11 and the second-stage telescopic arm 12, which are driven by a two-stage double-acting actuator 19, and the piston rod of the two-stage double-acting actuator 19 is used for driving. The end and the bottom end of the cylinder are respectively connected with the secondary telescopic arm 12 and the fixed arm 8. The front end support slider 13 is installed on the inner side of the front end of the fixed arm 8, and the tail end support slider 14 is installed on the outer side of the tail end of the primary telescop...

Embodiment 3

[0047] The cutting unit 7 can also be a three-stage cutting unit 29, which can overcome the structural size of the ineffective stroke of the actuator 17 due to the too small pile hole, and the radially driven telescopic arm of the two-stage cutting unit 28 is non-shaped cutting and undercutting drill. It cannot meet the regulatory requirements of 3 times the diameter expansion ratio. The three-stage cutting unit 29 telescopic arm 9 is divided into two stages, namely the first-stage telescopic arm 11 and the second-stage telescopic arm 12, which are driven by a three-stage double-acting actuator 20, and the piston rod end of the third-stage double-acting actuator 20 is used. and the bottom end of the cylinder are respectively connected with the secondary telescopic arm 12 and the fixed arm 8, the front end support slider 13 is installed on the inner side of the front end of the fixed arm 8, the tail end support slider 14 is installed on the outer side of the tail end of the prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com