Side window type crossing radiation gas detector

A gas detector and radiator technology, applied in radiation intensity measurement and other directions, can solve the problems of limited count rate, slow time response, harsh process, etc., and achieve the effect of improving service life, easy large-area production, and good spatial resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

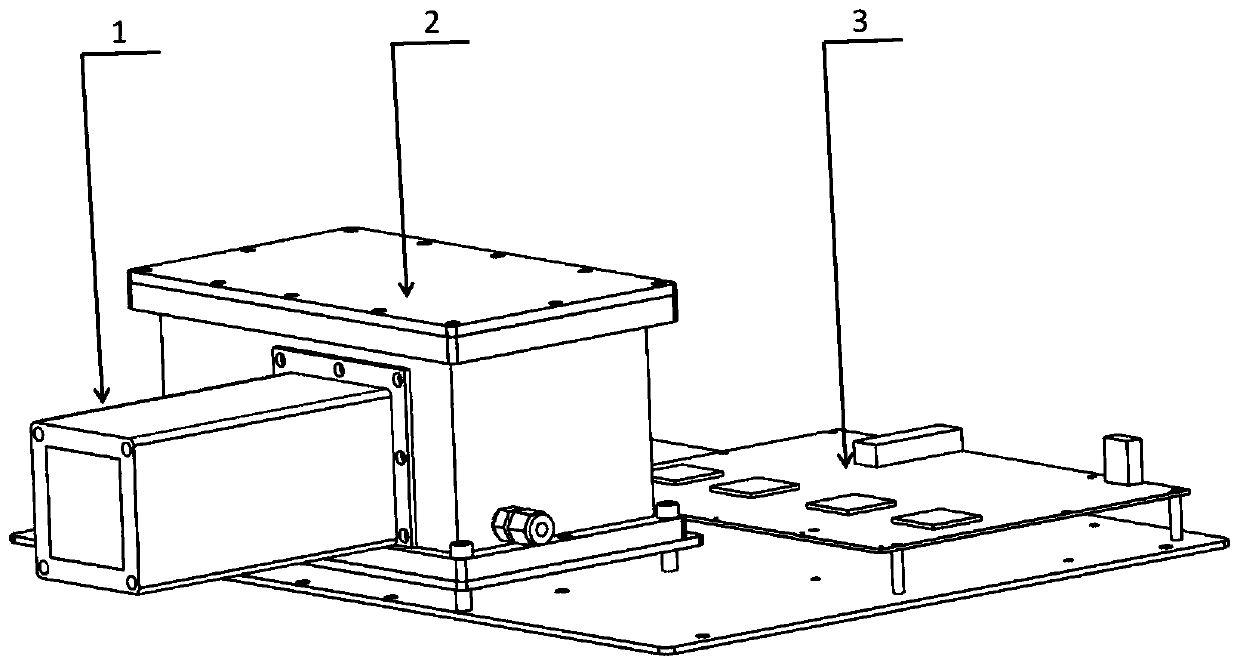

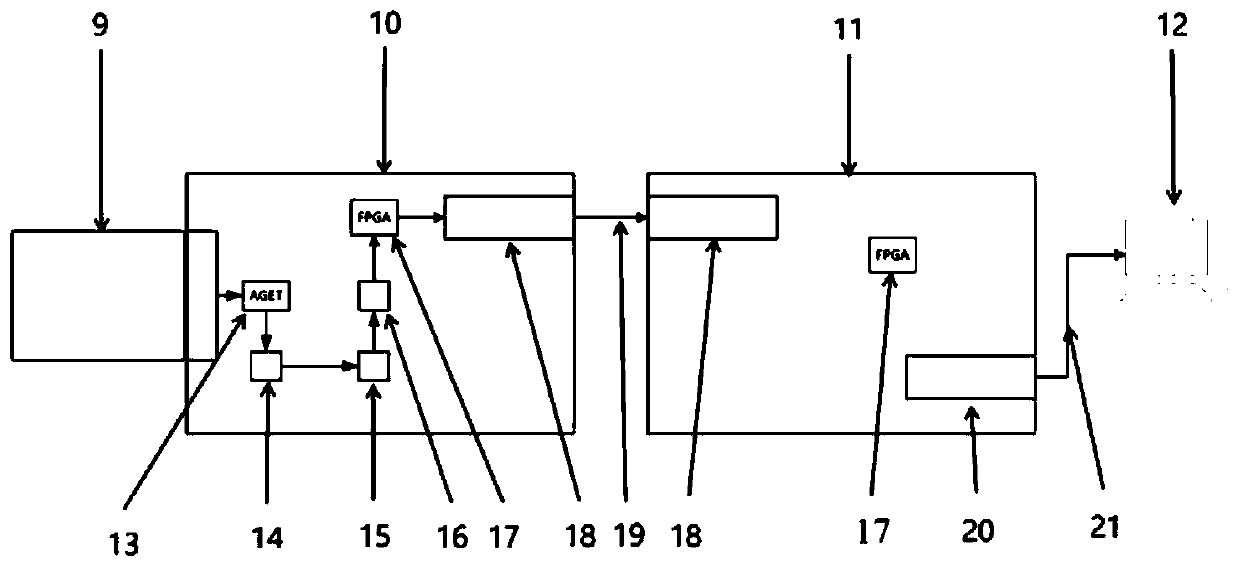

[0030] Such as Figure 1 to Figure 4 As shown, the side-window radiation passing gas detector according to the present invention includes a radiator 1 , a gas detector 2 and a readout electronic system 3 . The specific structure and connection relationship are:

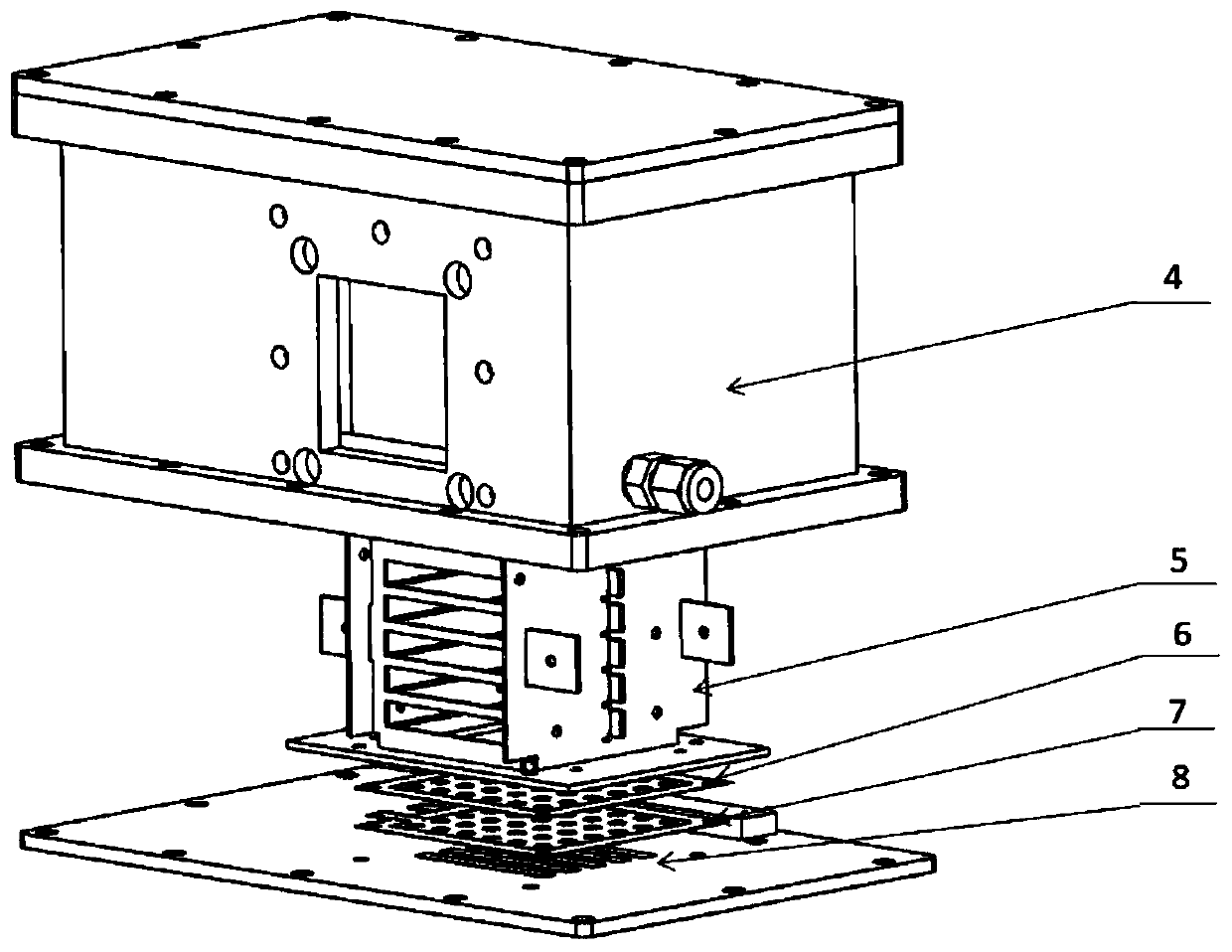

[0031] The radiator 1 is a regular radiator with a multi-layer structure formed by stacking multiple layers of materials with different dielectric constants. The foil material is polypropylene, and air is selected as the gap material. Use glue to stick the polypropylene foil to the PCB spacer frame, then stack each layer of foil together, and fix it with screws to form a multi-layer radiator.

[0032] Described gas detector 2 comprises chamber 4, field cage 5, the first thick type gas electron multiplier membrane plate 6, the second thick type gas electron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com