Cadmium-based metal-organic framework material as well as preparation method and application thereof

An organic framework, metal-based technology, applied in the field of advanced porous and luminescent materials, can solve the problems of MOF materials such as microscopic reaction process, topology and performance are difficult to predict, poor thermal stability and water stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take the material according to the following specific mass or volume: H 4 etc(17.3mg, 0.05mmol), tpt(15.5mg, 0.05mmol), Cd(NO 3 ) 2 4H 2 O (30.8 mg, 0.1 mmol), CH 3 CN (3mL), H 2 O (7 mL). Put the above material in 25mL polytetrafluoroethylene liner, stir for about 0.5h, seal it in a stainless steel reaction kettle, place the reaction kettle in an electric blast oven and raise the temperature to 140°C, after 4 days of reaction, cool naturally to room temperature, A bulk crystal sample was obtained, which was filtered from the mother liquor, washed with distilled water, and dried naturally in air at room temperature.

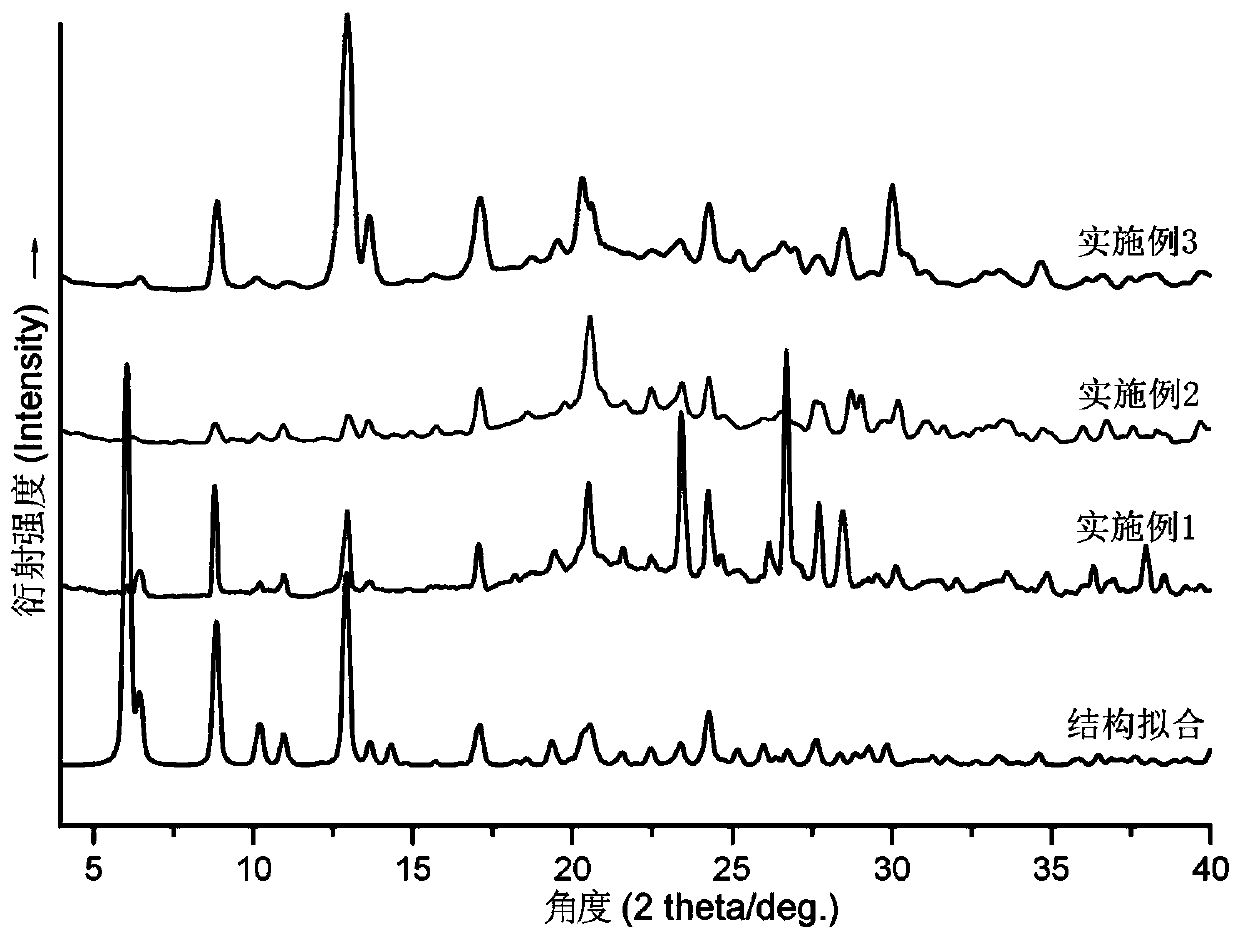

[0032] To the prepared crystal sample, carry out powder diffraction test with Shimadzu XRD-6100 type X-ray diffractometer (see figure 1, abscissa—angle; ordinate—diffraction intensity), the peaks of the test spectrum and the peaks of the crystal structure simulation spectrum (software Mercury) can be well matched, indicating that the structure of the...

Embodiment 2

[0049] Take the material according to the following specific mass or volume: H 4 etc(17.3mg, 0.05mmol), tpt(15.6mg, 0.05mmol), Cd(NO 3 ) 2 4H 2 O (30.8 mg, 0.1 mmol), CH 3 CN (3mL), H 2 O (7mL), HNO 3 solution (30uL, 7mol / L, 0.21mmol). Put the above material in 25mL polytetrafluoroethylene lining, stir for about 0.5h, seal it in a stainless steel reaction kettle, place the reaction kettle in an electric blast oven and raise the temperature to 160°C, react for 5 days, and cool it down to room temperature naturally. A bulk crystal sample was obtained, which was filtered from the mother liquor, washed with distilled water, and dried naturally in air at room temperature.

[0050] The product was characterized by powder X-ray diffraction, and the data obtained were similar to those in Example 1. It shows that the crystal structure prepared by Example 2 does not change, and the product has a higher purity.

[0051] This embodiment is repeated several times, and actually obta...

Embodiment 3

[0053] Take the material according to the following specific mass or volume: H 4 etc(17.3mg, 0.05mmol), tpt(15.6mg, 0.05mmol), Cd(NO 3 ) 2 4H 2 O (30.8 mg, 0.1 mmol), CH 3 CN (3mL), H 2 O (7 mL). Put the above material in 25mL polytetrafluoroethylene liner, stir for about 0.5h, seal it in a stainless steel reaction kettle, place the reaction kettle in an electric blast oven and raise the temperature to 150°C, react for 6 days, and cool it down to room temperature naturally. A bulk crystal sample was obtained, which was filtered from the mother liquor, washed with distilled water, and dried naturally in air at room temperature.

[0054] The product was characterized by powder X-ray diffraction, and the data obtained were similar to those in Example 1. It shows that the crystal structure prepared by Example 2 does not change, and the product has a higher purity.

[0055] This embodiment is repeated many times, Cd 2 - The quality of MOF is maintained at 17.2-21.3 mg, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com