Aluminum-ion battery using MoS2 as positive electrode material and preparation method of battery

A technology for aluminum ion batteries and cathode materials, which is applied in nanotechnology for materials and surface science, electrolyte battery manufacturing, battery electrodes, etc., can solve problems such as high cost and limited safety hazards, reduce preparation costs, and promote development. , the effect of good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

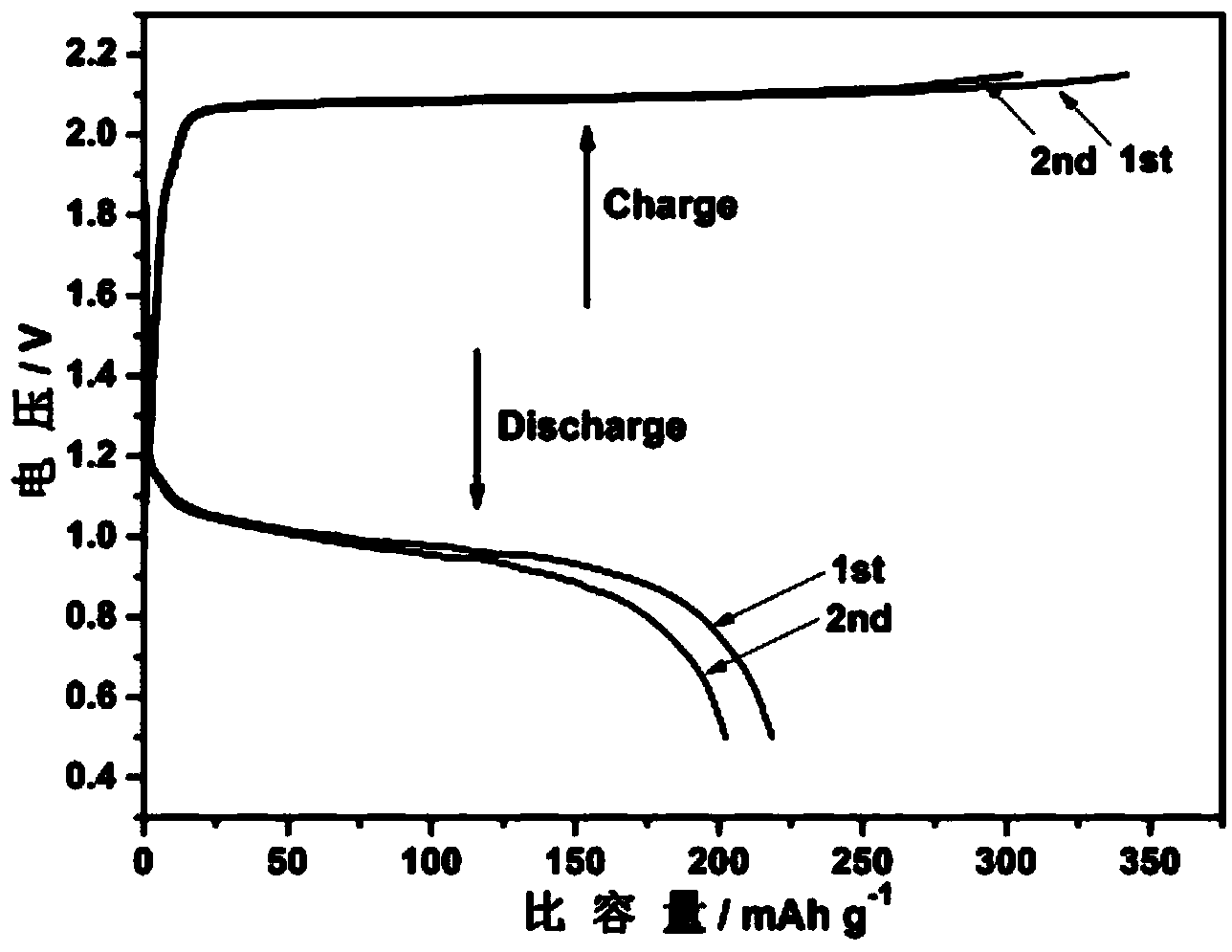

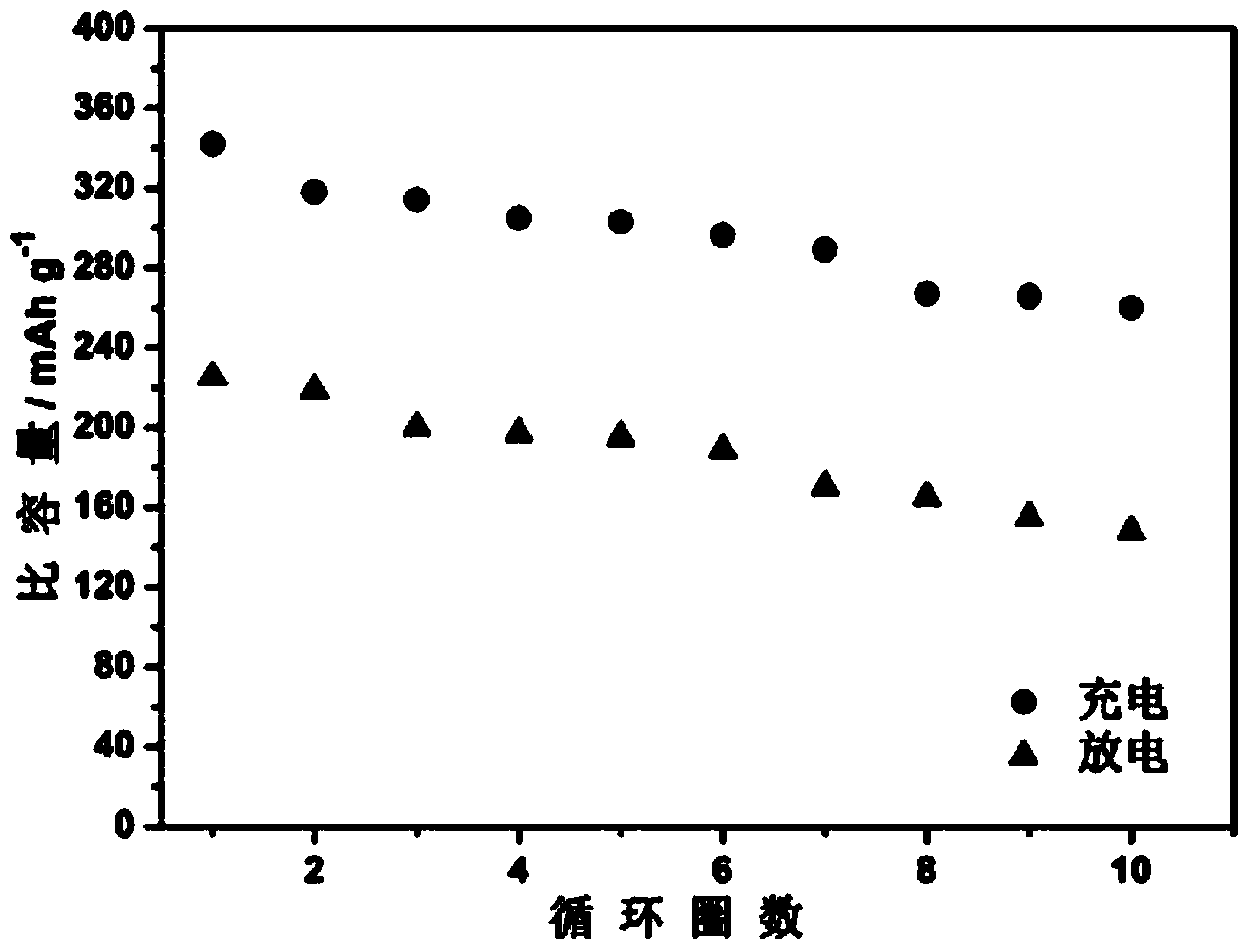

[0031] use MoS 2 As the positive active material, the positive plate is assembled according to MoS 2 : The mass ratio of platinum slurry is 70:30 and mixed evenly, then evenly spread the gel on the molybdenum sheet of 10mm×20mm, and finally put it in an oven at 60-120 degrees Celsius for more than 12 hours and dry it with GF / The D separator material is wrapped as the positive electrode of the battery. The negative electrode is high-purity aluminum, which is soaked in absolute ethanol for 1-2 hours, dried by ultrasonic vibration, and then cut into a sheet of 10mm×20mm as the negative electrode. Anhydrous aluminum chloride and 1-ethyl-3-methylimidazolium chloride are formulated into an ionic liquid in a glove box in an argon atmosphere at a mass ratio of 1.3:1, as an electrolyte for an aluminum ion battery of the present invention. Finally, the prepared positive electrode, negative electrode and electrolyte were assembled into a battery in the glove box. After the battery is...

Embodiment 2

[0033] use MoS 2 As the positive electrode active material, it is mixed with the conductive material Super-P and the binder polytetrafluoroethylene (PTFE) at a mass ratio of 75:15:10, added to absolute ethanol for dispersion, and ultrasonically Shake for 20-30 minutes and mix evenly, then put it in an oven at 60 degrees Celsius and bake until it becomes gel, then spread the gel evenly on a molybdenum sheet of 10mm×20mm, and finally put it in an oven at 60-120 degrees Celsius for more than 12 hours to bake After drying, wrap it with GF / D diaphragm material as the positive electrode of the battery. The negative electrode is high-purity aluminum, which is soaked in absolute ethanol for 1-2 hours, dried by ultrasonic vibration, and then cut into a sheet of 10mm×20mm as the negative electrode. Anhydrous aluminum chloride and 1-ethyl-3-methylimidazolium chloride are formulated into an ionic liquid in a glove box in an argon atmosphere at a mass ratio of 1.3:1, as an electrolyte for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com