Preparation method of lithium ion battery anode material

A lithium-ion battery, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unstable structure and poor cycle performance, and achieve improved mass specific capacity, better cycle performance, and cycle capacity maintenance. rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Will Co 3 o 4 、Al 2 (SO 4 ) 3 , and Li 2 CO 3 According to the chemical formula LiAl x co 1-x o 2 Mole ratio n(Li 2 CO 3 ):n(Al 2 (SO 4 ) 3 ):n(Co 3 o 4 )=1:x:[2(1-x) / 3] Take the corresponding above-mentioned raw materials. In this embodiment, x=0.15, that is, by molar ratio n(Li 2 CO 3 ):n(Al 2 (SO 4 ) 3 ):n(Co 3 o 4 )=1:0.15:0.57 Take the corresponding above-mentioned raw materials. Mix the above raw materials, add absolute ethanol to disperse, wet grind for 4 hours, evaporate to remove absolute ethanol, dry, grind, increase the temperature in the air at a rate of 60°C / hour, and roast at a constant temperature of 850°C for 14 hours. Then drop to room temperature at a rate of 40°C / hour to obtain LiAl 0.15 co 0.85 o 2 product.

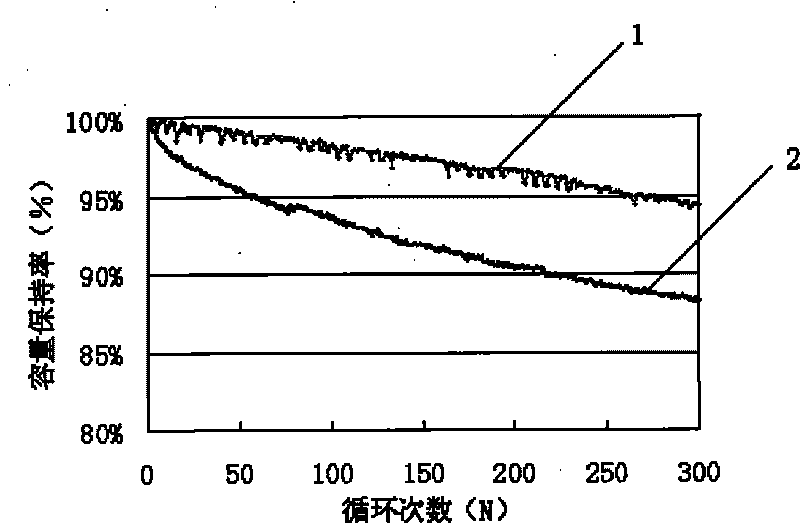

[0020] The above materials were applied to 18650-2.2Ah cylindrical batteries, and their mass specific capacity and cycle capacity retention were tested, and compared with undoped LiCoO 2 For comparison, the results ar...

Embodiment 2

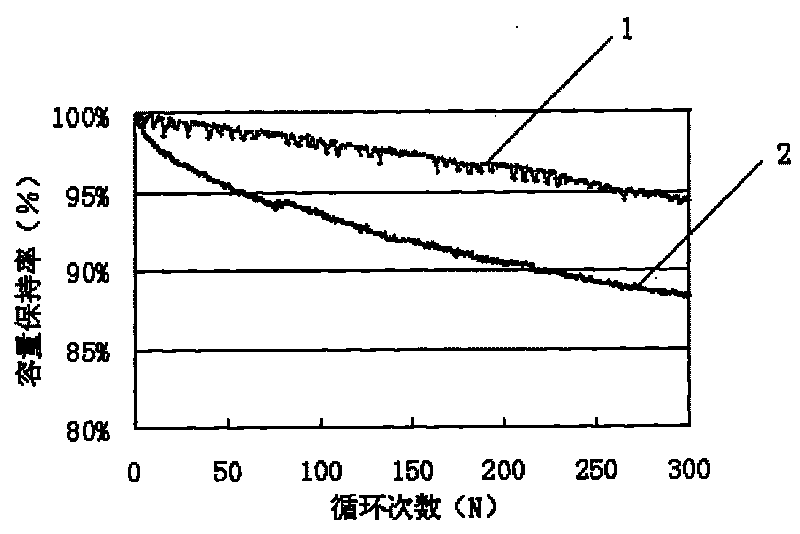

[0024] On the basis of Example 1, under the condition that other conditions remain unchanged, the wet milling time is changed to 3h, 4h and 5h, and the performance of the product is as follows:

[0025] performance / milling time

Embodiment 3

[0027] On the basis of Example 1, under the condition that other conditions remain unchanged, the calcination temperature is changed to 800°C, 850°C and 900°C, and the properties of the product are as follows:

[0028] Properties / Firing temperature

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com