A kind of high damping graphene/polymer composite material and preparation method thereof

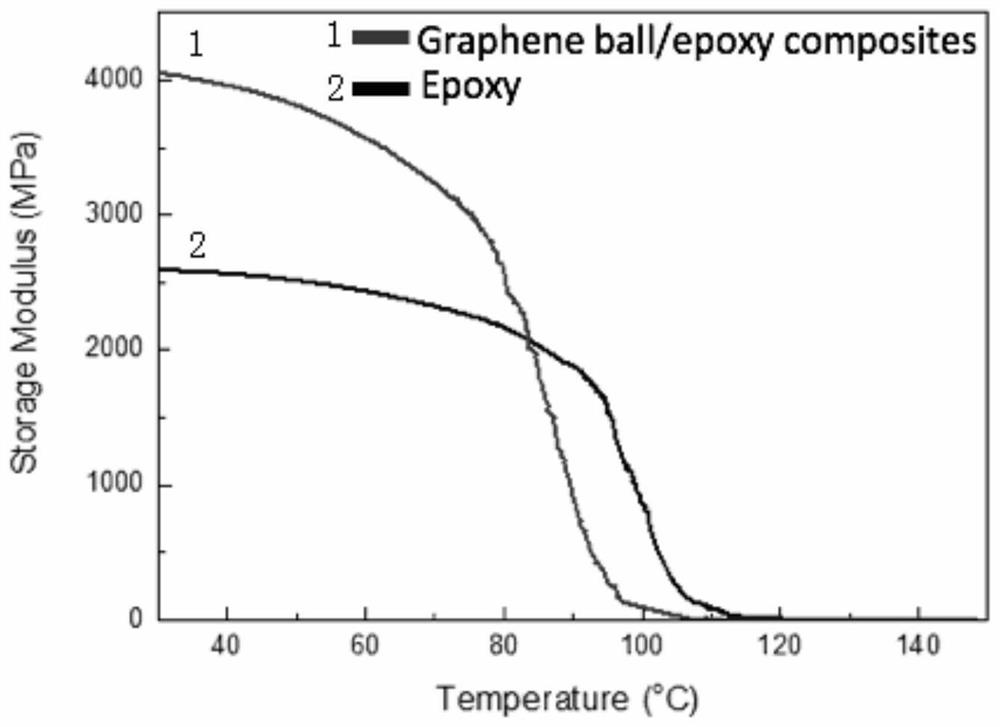

A composite material and graphene technology, which is applied in the field of high damping graphene/polymer composite materials and its preparation, can solve the constraints on the application of graphene/polymer matrix composite materials, the decline in the damping performance of graphene/polymer composite materials, etc. problems, to achieve the effect of improving mechanical strength and damping performance, improving mechanical properties, and excellent damping characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the present embodiment, a kind of high-damping graphene composite material, the content of each component is calculated by weight parts:

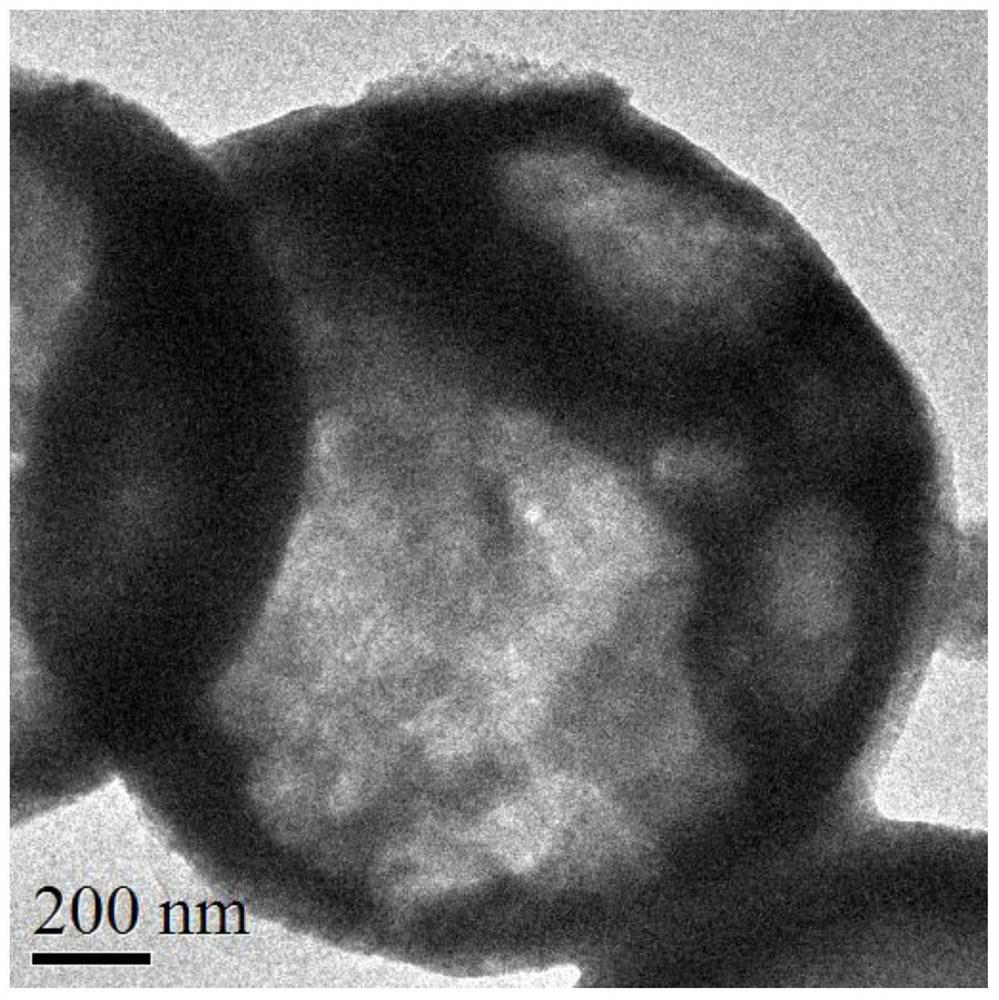

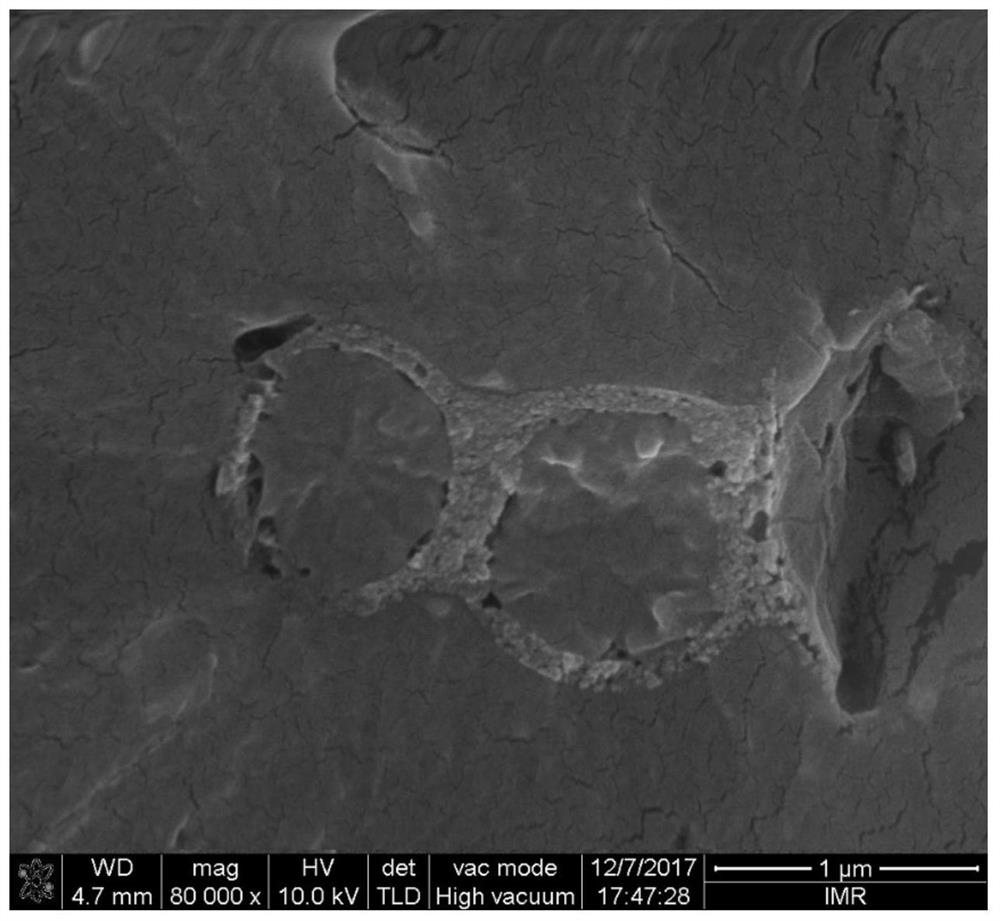

[0032] Spherical graphene prepared by spray drying method: 0.01 part; spherical graphene is a hollow spherical structure, wherein the spherical graphene particle size distribution range is between 1 and 5 microns, and the thickness of the outer wall of the hollow spherical shape is between 0.1 and 0.2 microns;

[0033] T31 epoxy resin curing agent: 25 parts;

[0034] E51 epoxy resin: 100 parts;

[0035] Other fillers: 0 parts;

[0036] The preparation method of described high damping graphene composite material is as follows:

[0037] Weigh 0.01 parts of spherical graphene, add it to 25 parts of T31 epoxy resin curing agent, ultrasonically disperse for 30 minutes under 500W power ultrasound, and magnetically stir evenly; the uniformly dispersed spherical graphene / T31 epoxy resin curing agent mixed system Add it into the epoxy res...

Embodiment 2

[0040] In this embodiment, a high damping graphene composite material, the content of each component is calculated in parts by weight:

[0041] Spherical graphene prepared by spray drying method: 0.1 part; spherical graphene should be a hollow spherical structure, wherein the spherical graphene particle size distribution range is between 0.5 and 1 micron, and the thickness of the outer wall of the hollow spherical shape is between 0.05 and 0.1 micron;

[0042] T31 epoxy resin curing agent: 25 parts;

[0043] E51 epoxy resin: 100 parts;

[0044] Carbon nanotube: 0.05 parts;

[0045] The preparation method of described high damping graphene composite material is as follows:

[0046] Weigh 0.1 parts of spherical graphene, add it to 25 parts of T31 epoxy resin curing agent, ultrasonically disperse for 40 minutes under 500W power ultrasound, and magnetically stir evenly; the uniformly dispersed spherical graphene / T31 epoxy resin curing agent mixed system and 0.05 parts of carbon...

Embodiment 3

[0049] In this embodiment, a high damping graphene composite material, the content of each component is calculated in parts by weight:

[0050] Spherical graphene prepared by spray drying method: 0.5 parts; spherical graphene should be a hollow spherical structure, wherein the spherical graphene particle size distribution range is between 5 and 10 microns, and the thickness of the outer wall of the hollow spherical shape is between 0.1 and 0.2 microns;

[0051] T31 epoxy resin curing agent: 30 parts;

[0052] E51 epoxy resin: 100 parts;

[0053] Nanoclay: 0.1 part;

[0054] The preparation method of described high damping graphene composite material is as follows:

[0055] Weigh 0.5 parts of spherical graphene, add it to 30 parts of T31 epoxy resin curing agent, ultrasonically disperse for 60 minutes under 800W power ultrasound, and magnetically stir evenly; the uniformly dispersed spherical graphene / T31 epoxy resin curing agent mixed system and 0.2 parts of nanoclay were a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com