A kind of biomass gasification furnace ash discharge system

A gasifier and biomass technology, which is applied in the field of gasifiers, can solve the problems of excessive heavy metal content in ash and slag, large impact on the human body when dealing with dust, and high heat loss rate, so as to achieve convenient and fast maintenance and ash work. Humanization, the effect of improving the efficiency of ash extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

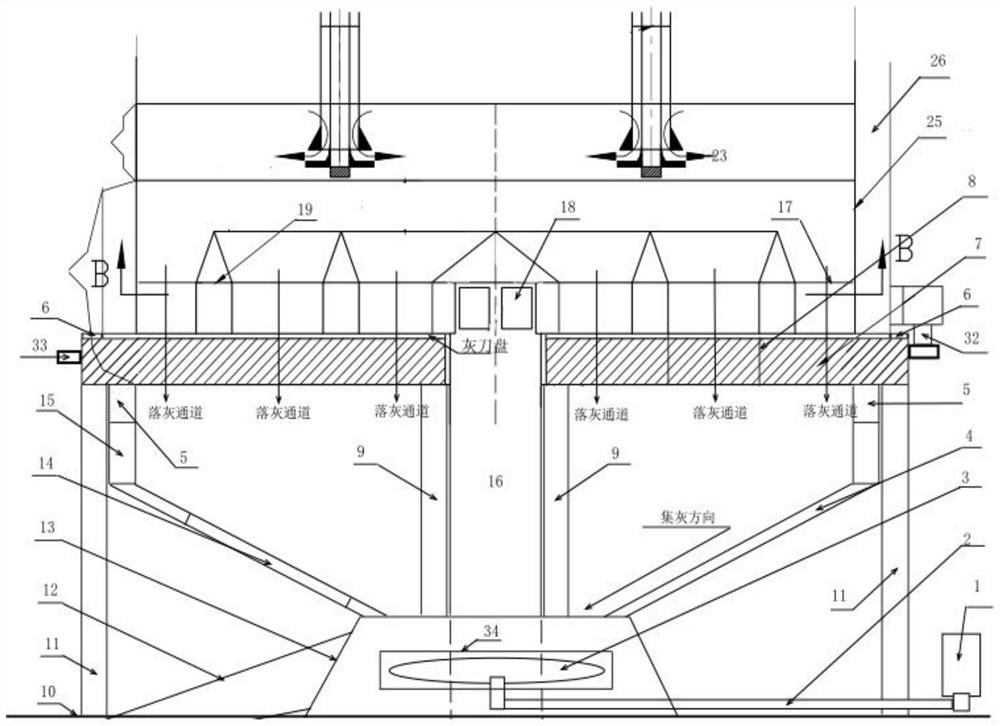

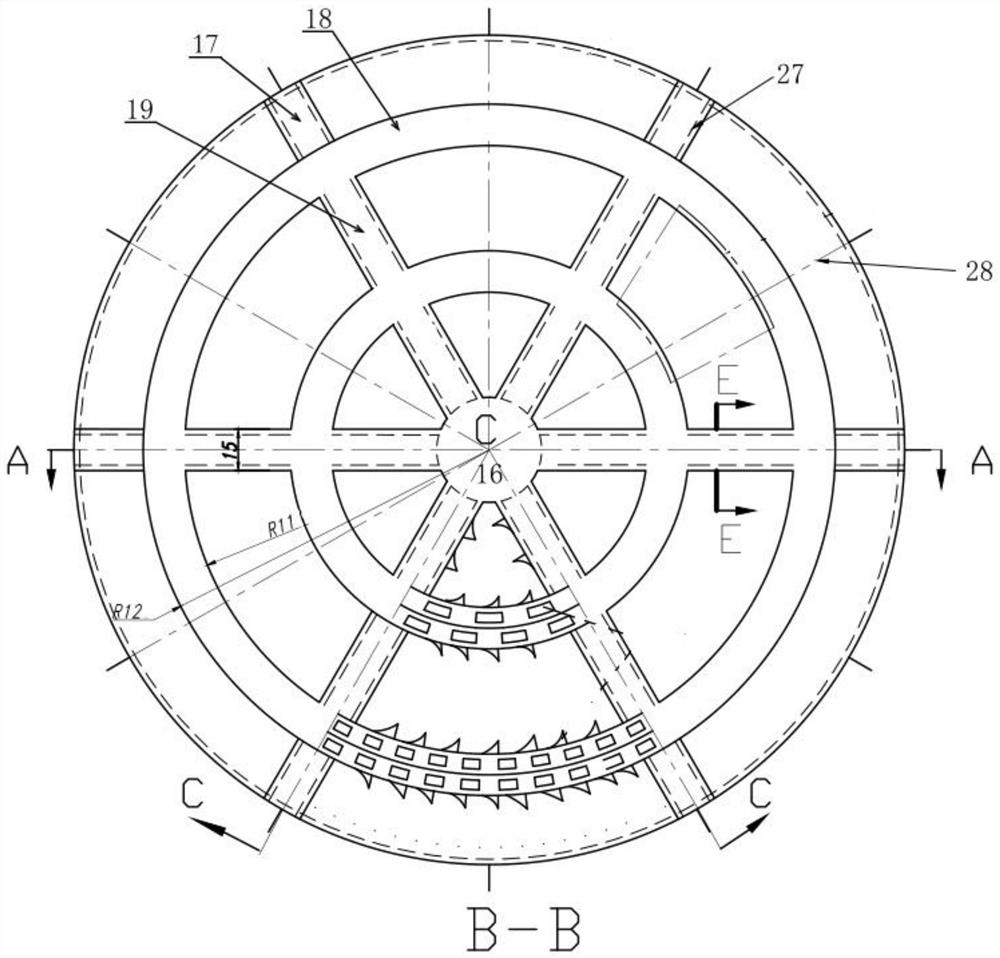

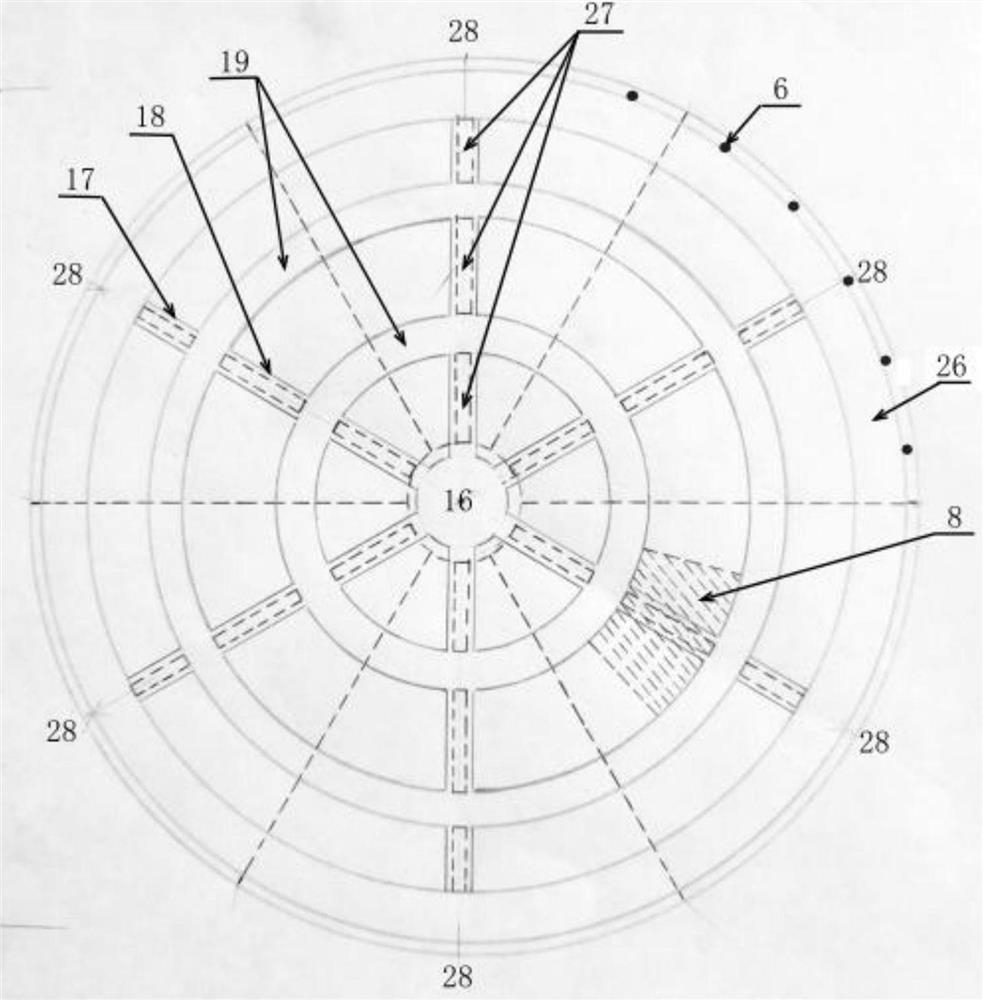

[0039] like Figure 1 to 4 A biomass gasification furnace outflower system, from top to bottom, including ash channel systems, an empty system, a gray system, and a grazing output system, the ash channel system inside the furnace body 25, Extreme system, set ash system and gray residue output system at the bottom of the furnace body 25;

[0040] The ash channel system is a disc-shaped furnace gate; the disc-shaped furnace gate includes an in-air pipe 16, a main wind tube reinforcing tube 17, a main wind tube 18, and a barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com